|

Title: |

1911 Article-Jones & Lamson Machine Co., New Flat Turret Lathe Plain Turning Tools, Rotary Turner & Cross Slide |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V1, 1911, pg. 87-88 |

|

Insert Date: |

4/18/2022 5:00:41 PM |

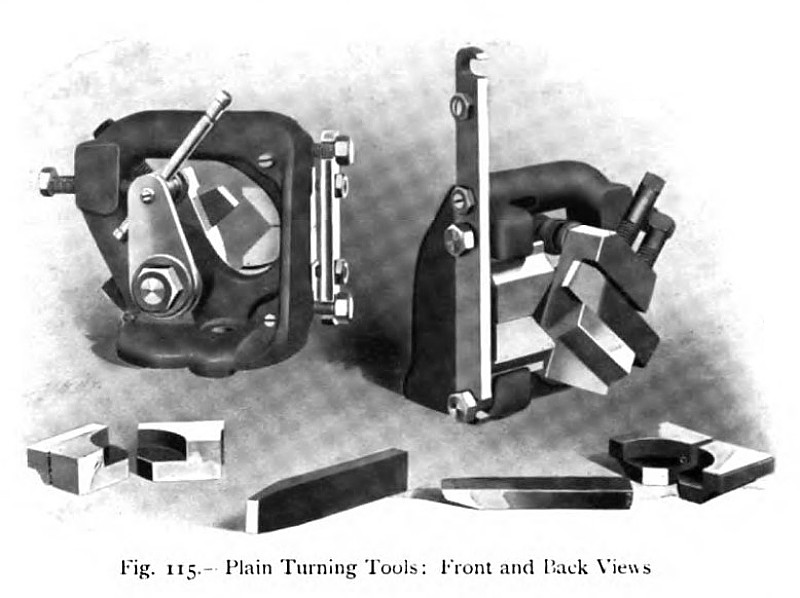

The plain turning-tool arrangement, suitable for bar work, is illustrated in fig. 115. In this case the cutting tool is a rough piece of 1-in. by 1/2-in. high-speed steel, carried in a pivoted tool-block of forged steel, which, in turn, is mounted upon the tool-box frame, as shown in the illustration. As this tool is not intended for very rapid work, it is provided with ordinary fixed back rests, which are capable of adjustment, and which can also be readily removed, together with the cutter, to enable the turner to pass over a large-diameter portion of the work. The frame of the toolbox is hollow, and serves as a conduit for the oil, which enters through a hole in the base and emerges at the oblong hole visible in the figure over the cutter. Owing to the use of simple back rests, this tool can deal with all diameters of bar work, within the range of the machine, down to sizes of 3/8 in. or even less diameter, whereas, in the case of the roller-back-rest arrangement, the smallest diameter that can be dealt with is 5/8 in. This latter tool is shown in fig. 116, mounted in position on the turret; and one of the rolls is shown separately in the hand of the operator. Two independent adjustments are provided for turning two different diameters and as in the previous case, the parts can be rapidly opened to pass a large diameter portion of the work, and then quickly closed again to whichever of the two sizes the tool is set for. The rolls may be set to precede or follow the cutter, and the tool can operate when moving towards or from the chuck.

When the cutters are carried upon a cutter bar, as indicated in fig. 113, the bar is securely mounted in tool-holders of the type illustrated in fig. 117, which are also used for drill chucks, reamers, taps, and similar parts. In the same figure is illustrated the turret cross slide, which serves for cutting off the bar or for holding a forming tool. The cutting tool is held in a sliding block, gibbed to the frame, which is securely bolted down upon the turret face; and it will be seen that the tool is placed close to the sliding surfaces, to reduce, as far as possible, the effect of any slight slackness of the guides. A pinion gears with a rack on the tool slide and, by means of the long hand lever, the latter can be fed against the work for cutting-off purposes.

In certain of the tools the cutting edge is ground to an acute angle of from 45 to 55 degrees, instead of about 70 degrees, as is common practice. The metal is, therefore, wedged off instead of being scraped away, and the keenness of the cutting edge is preserved for a longer period than is the case with tools of less acute angles. Difficulty is often experienced, in the use of sharp-angled tools, through the edge being too weak to stand the severe cutting strain; but, in the present example, the difficulties are overcome by giving the tool practically no clearance, and by holding the tool in such a way that it can adjust itself until its face rests upon the work.

Under such conditions the two faces of the sharp cutting edge bear against, and are supported by, the work and the chip respectively; the latter being wedged off rather than scraped away. It will be evident, therefore, that the tendency to break down the cutting edge is greatly diminished. To enable the cutter to adjust itself to the work, the underside, which rests on the cutter block, is curved to a cylindrical form, the axis of which approximately coincides with the cutting edge. |

|

1911 Jones & Lamson Machine Co., New Flat Turret Lathe Plain Turning Tools

1911 Jones & Lamson Machine Co., New Flat Turret Lathe Plain Turning Tools

1911 Jones & Lamson Machine Co., New Flat Turret Lathe, Rotary Turner

1911 Jones & Lamson Machine Co., New Flat Turret Lathe, Rotary Turner

1911 Jones & Lamson Machine Co., New Flat Turret Lathe, Turning Tool Holder & Cross Slide

1911 Jones & Lamson Machine Co., New Flat Turret Lathe, Turning Tool Holder & Cross Slide

|

|