|

Title: |

1909 Article-J. A. Fay & Egan Co. #227 Twin Band Saw |

|

Source: |

Woodcraft Nov 1909 |

|

Insert Date: |

12/17/2015 7:58:19 PM |

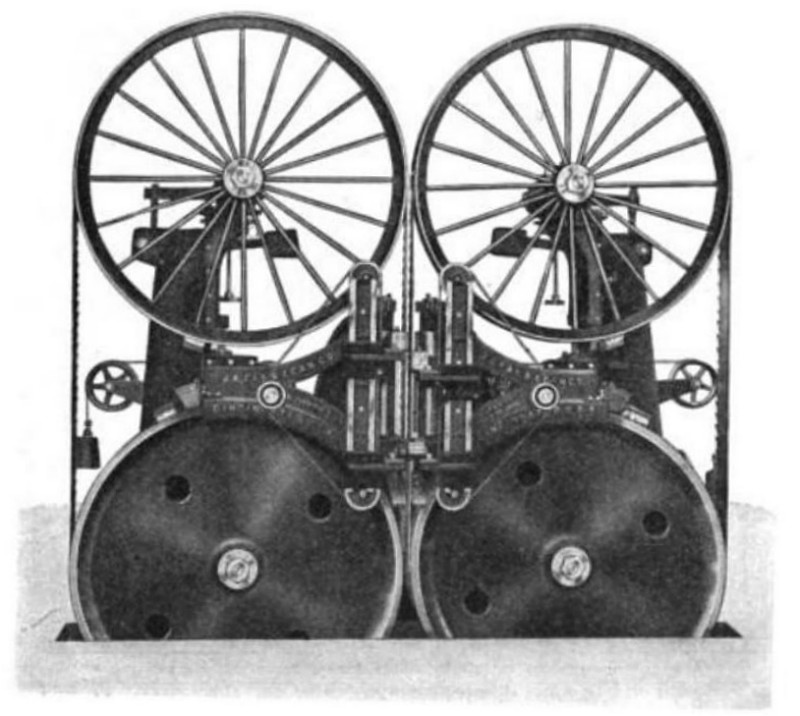

Fay & Egan's Twin Band Resaw

The J. A. Fay & Egan Co., Cincinnati, illustrates herewith the latest production in the line of resaws, the No. 227 twin band resaw. The machine will resaw timbers up to 24 inches wide and 10 inches thick. It will saw a board into three pieces 3/16 inch thick, or three of any other thickness up to 3 inches each. It will saw one piece 3, one 6 and one 1 inch, or any combination less than these. By adjusting the movable saw out of the way, the machine may be used as an ordinary resaw, sawing up to 3 inches on one side and 6 inches on the other.

The Fay & Egan Co., in describing this machine, calls attention to its valuable and novel features of merit thus:

The feed consists of four rolls heavily geared and driven by variable frictions. The first rolls are 5 inches in diameter and the second 4 inches, bringing them very close to the blade and permitting the feeding of short pieces. The rolls may be set for self-centering or with one pair rigid. They are provided with foot treadle to open them instantly and release the stock. The mechanism is under instant control by lever convenient to the operator and is provided with an automatic lock.

The frame is a massive cored casting on which are mounted the housings carrying the upper wheel bearings and those carrying the feed rolls.

The straining device is the manufacturer's patent knife-edge balance. The upper wheel is hung solely on a knife-edge and counterbalanced by a compound lever and weights. It is said to be the most sensitive strain known and is claimed to enable the machine to run at twice the speed of other resaws at the same time carrying the thinnest gage blade without danger of buckling or breaking.

The wheels are 54 inches in diameter, are very heavy (the lower one being solid) and are taper fitted to shafts running in self-oiling bearings. The upper wheels are fitted with steel spokes cast solid to the rims and hubs. The bearings are carried on saddles which are fitted in wide dovetail ways with gib take-up for wear. The rising screws are mounted on ball bearings for ease of adjustment. The lower wheel bearings, on the stationary side of the machine, are carried in the base, and on the adjusting side they are mounted in hangers suspended from movable housings, making the machine entirely self-contained.

The saw guides are new wood block type with brass plates between the blades. They are fitted with hand wheels and rope drums, permitting them to be adjusted from where the operator stands, and requiring nothing to be moved when taking off the saw blades. |

|

1909 J. A. Fay & Egan Co. Twin Band Saw

1909 J. A. Fay & Egan Co. Twin Band Saw

|

|