|

Title: |

1871 Article-Taylor, Williams and Jordan, Wood Carving Machine |

|

Source: |

Scientific American, V24, #17, 22 Apr, 1871, pg. 255 |

|

Insert Date: |

9/12/2020 7:05:33 PM |

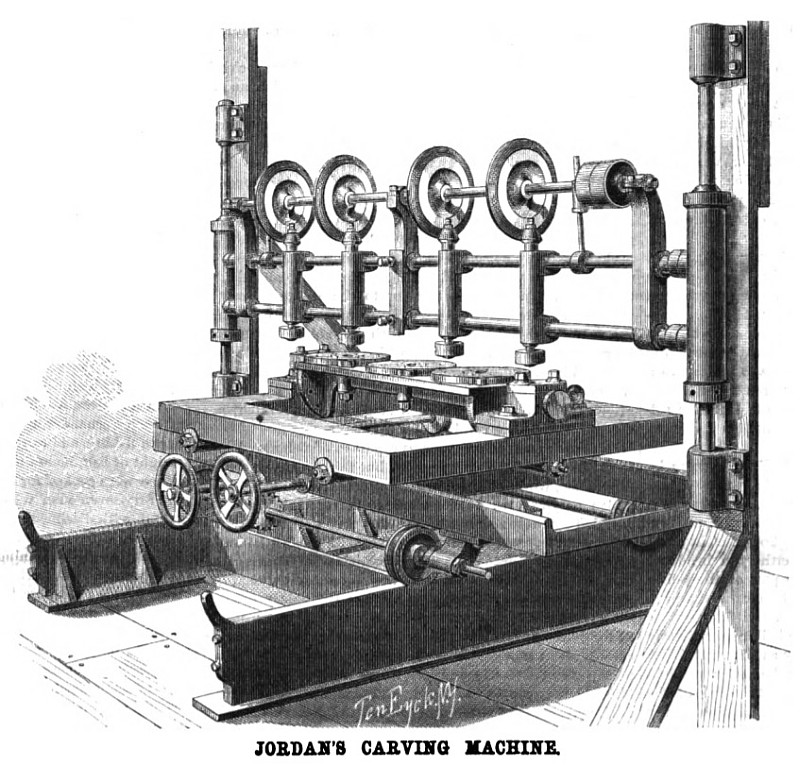

This machine, the engraving and description of which we copy from Engineering, was specially designed by its inventor, Mr. Jordan, for assisting in the production of the vast amount of carved decorations required for the walls and ceilings of the Houses of Parliament, London, and it was so employed during the entire progress of the work. The late Sir Charles Barry was so well satisfied with it, that he frequently declared it would have been impossible to have accomplished the work without it. The department of Woods and Forests employed five of the machines at the Government Works, Thames Bank, for several years; and the machines have now passed into the hands of Messrs. George Trollope and Son, and are still used in the same building. Other leading firms have them in use, and the works first established, by the patentee, at Belvedere road, are still in full operation, principally on church fittings. The new machines are like the originals in principle and general construction, but are greatly improved in some of the details, especially in those which tend to facilitate the production of works on the round, or such as require a large amount of under and through cutting. The large machine consists of two principal parts: the first, a horizontal part, is a bedplate having two parallel rails, on which a frame, fitted with double-flanged wheels, travels; this frame, in like manner, presents two parallel rails at right angles to the former, on which the top casting, or floating table, rolls by its wheels, for flat work, such as the paneling of the House of Lords. This iron table is covered with wood, as the readiest means of fixing the work to it; but for round work another apparatus is fixed on it, called a turntable; this is fitted with three chucks, which revolve in it and are identically divided by deep square notches in their edges; and the table is fitted with detaining latches, which fall into the notches and keep each chuck securely fixed, in any position the workman gives it, in the plane of the table. The table itself is also fitted to revolve in bearings, which are fixed on the permanent horizontal table of the machine, and the motion can also be arrested, and the table fixed at any angle given it by the workman. The pattern, of which it is desired to make copies, is fixed on the center chuck, and the pieces of wood, or other material for the work, are fixed on the other two chucks.

The second or vertical part of the machine is supported by side columns from floor to ceiling. It consists of a stiff parallel frame, which extends across the horizontal portion of the machine, and is fitted with mandrils which carry the carving tools, and a central head which carries the tracer. The whole of this frame is capable of motion in a vertical plane only, and its weight is very nearly balanced by a heavy treadle, with which it is connected by overhead levers and suspension rods, in such a way as to bring the vertical motion of the cutter and tracer under the management of the workman's foot.

The revolution of the cutters at the high velocity required is obtained by beveled friction gearing, in which the elasticity of vulcanized rubber is well introduced.

The manipulation of the machine will now be readily understood. The workman takes his stand in front of the machine, with one hand on each of the hand wheels, and one foot on the treadle; with the right hand he can traverse the table from side to side; with the left, he can roll it to or from him, and by aid of these two motions he can bring any point of the pattern under the tracer; and since the cutters on each side are at the same distance from it as the centers of the respective chucks, they will always have the same relative positions to the blocks being carved. Hence, when the tracer has in succession been brought in contact with every point of the pattern, two exact copies of it will have been produced. But, in order to bring every point of a round pattern under the tracer, it is requisite to present all its sides upwards at various angles, and this is done by the two revolving motions of the turntable, previously described.

Mr. Jordan has also brought out a smaller machine, to be worked by hand wheel, which is capable of carving any statuette, or other subject within its range; this he calls the amateur carving machine, and, we doubt not, it will shortly become popular with the lovers of mechanical art, since it is capable of producing very closely elaborate work in hard or soft wood, ivory, alabaster, and marble, or in any other material which can be worked with a steel drill; and, indeed, we see no reason why it should not be applied to the harder materials, also, by substituting the abrasive tools of the lapidary for the steel cutters.

GB Patent: GB-184,510,525

http://datamp.org/patents/displayPatent.php?number=184510525&typeCode=0 |

|

1871 Taylor, Williams and Jordan, Wood Carving Machine

1871 Taylor, Williams and Jordan, Wood Carving Machine

|

|