|

Title: |

1911 Article-D. & J. Tullis, #1 Radial Drill Press |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V2, 1911, pgs. 22-23 |

|

Insert Date: |

4/20/2020 12:58:28 PM |

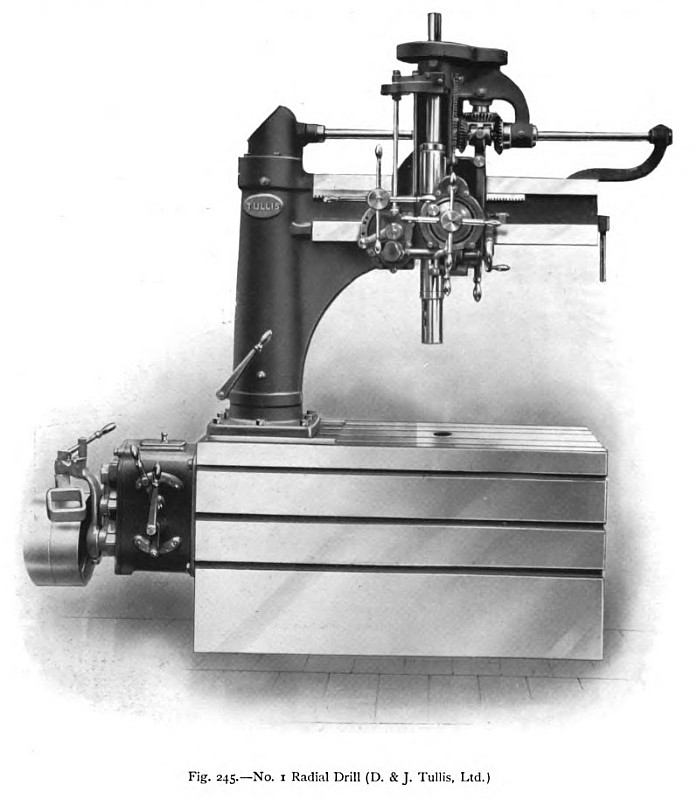

A compact and rigid radial machine, driven positively through gearing from a single high-speed belt-driven pulley, is illustrated in fig. 245, which represents the No. 1, 42-in. radius drilling and tapping machine manufactured by D. & J. Tullis, Ltd., of Clydebank. The column is mounted upon a table or foundation, which consists of a strong cast- iron box, provided on the top and sides with T slots, to which the work can be secured. The arm of the machine is carried by the column upon a ball bearing, which enables it to be freely rotated to the required position; and near the foot is provided a strong clamp operated by the hand lever shown in the illustration. Owing to the spindle saddle being mounted on the side of the arm, the latter has to withstand certain twisting forces, in addition to the bending forces due to the thrust of the drill. To withstand these forces the arm is of box section and is made exceptionally strong and rigid.

Upon the narrow-machined guide of the arm face is mounted the spindle saddle, which can be rapidly adjusted along the arm through a distance of 30 in. by means of a handwheel. A locking handle is also provided to prevent any motion of the saddle during the drilling operation. Friction, due to the thrust of the drill, is reduced by the use of a ball bearing, and the weight of the spindle is counterbalanced, so that it can be raised and lowered rapidly when the feed is released. The long spindle sleeve is fed by a rack-and-pinion gear through a distance of 15 in. It can be fed slowly by a hand worm and worm-wheel gear, or more quickly by means of the sensitive feed star handwheel shown at the front of the head. There are three self - acting feeds provided, namely, 60, 90, and 120 cuts per inch, and these may be changed immediately while the spindle is running. An automatic release gear, fitted with an indicator disk, disengages the worm of the feed gear and stops the feed when the drill reaches the desired depth, for which the release gear is set. Upon the end of the bed is mounted the change-speed box, from which a series of eight speeds ranging from 83 to 500 revolutions per minute can be obtained by the manipulation of the lever and hand- wheel shown. As already stated, the power is transmitted to the gears from a single constant-speed belt pulley, and there is, therefore, no exceptional loss of power at the lower speeds, as in the case of the cone-pulley arrangement. All the operating handles are placed within convenient reach of the operator and the machine can be readily controlled. |

|

1911 D. & J. Tullis, #1 Radiall Drill Press

1911 D. & J. Tullis, #1 Radiall Drill Press

|

|