|

Title: |

1911 Article-Webster & Bennett, Four Spindle Gang Drill |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V2, 1911, pgs. 11-13 |

|

Insert Date: |

4/13/2020 9:59:45 PM |

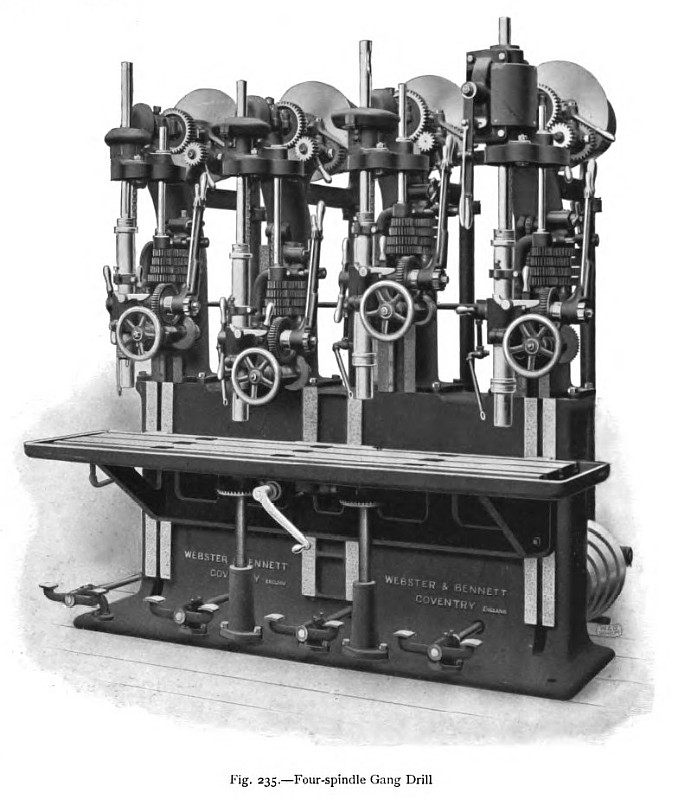

Greater rigidity, such as is required for the successful use of high-speed drills, is obtained by mounting the drill columns upon one strong base frame of box section, as in the example (fig. 235) of a four-spindle gang drilling machine manufactured by Webster & Bennett, Ltd., of Coventry. Each drill can be operated independently of the others, separate cone pulleys and gearing being provided; and the countershafts are carried upon the base at the rear, thus making the machine self-contained. There is one common table for the four spindles, the table being guided upon machined faces on the front of the base, and raised and lowered by two screws, operated by one handle through suitable bevel gearing. The work to be operated upon is moved by hand along the table from one spindle to the next, depending upon the sequence of operations; and in the particular machine illustrated the spindles are arranged for drilling, facing or recessing, reaming, and tapping operations. Any other sequence of operations can be provided for in the first instance. Thus, for example, two of the spindles instead of one can be f1tted with reversing gear for tapping, and a second drilling head can be substituted for the reaming head.

Eight speeds in geometrical progression are provided for each of the spindles, the speeds being arranged to suit the class of operations for which the sp1ndle is intended. At the side of each spindle will be seen the cone feed gears, from which four feed rates are obtained by suitably operating handwheels provided with indicating dials. Handwheels are also provided for facing and recessing, and ratchet levers for such operations as light drilling. In the case of the tapping spindle a ratchet lever is provided for starting the tap. In the machine illustrated the tapping spindle is at the right end, and the reversing handle is indicated at the top front side of the head. From the centre of the spindles to the front of the columns the distance is 10 in., and the maximum distance from the table in its lowest position to the spindle ends is 30 in. Between the spindle centres the spacing is 20 in., and the vertical feed of the spindles is 10 in. |

|

1911 Webster & Bennett, Four Spindle Gang Drill

1911 Webster & Bennett, Four Spindle Gang Drill

|

|