Image

|

Title: |

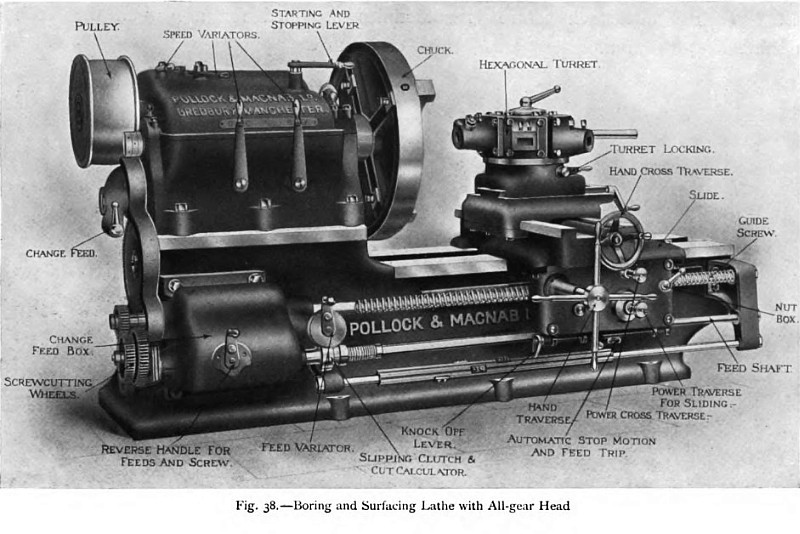

1911 Article-Pollock and MacNab, Ltd.-Boring & Surfacing Lathe |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V1, 1911, pgs. 34-35 |

|

Insert Date: |

4/1/2020 12:50:56 PM |

|

A typical example of the boring and surfacing lathes manufactured by Messrs. Pollock & Macnab, Limited, of Manchester, is illustrated in fig. 38. This machine is of the all-gear headstock type, driven by a single constant-speed pulley, an arrangement which ensures constant cutting power on all diameters within the capacity of the lathe. Sixteen direct spindle speeds are obtainable through the gears without countershaft multiplication, and the various speeds can immediately be applied by the suitable operation of the hand levers. If desired, a two-speed overhead countershaft can be used in conjunction with the geared head, in which case there are thirty-two speeds available. It is doubtful, however, whether the general need for so large a range of speeds is sufficient to warrant the use of a two -speed countershaft arrangement, which occupies valuable space and requires frequent supervision. The lathe is stopped and started by means of the horizontal lever on the top of the head, which operates a friction clutch on the pulley spindle. The carriage has automatic cross and sliding traverses in the forward and back ward directions, in addition to the screw-cutting motions, and the usual interlocking arrangements are fitted to prevent the engagement of the screw-cutting nut while the feed shaft is in use. When cutting odd threads, the nut can only be engaged correctly with the screw in certain positions, and to avoid the necessity of chalking the screw, as is frequently done, a revolving dial indicator is fitted on the apron so that the correct position can at once be found, and mis takes be avoided. Instant disengagement of the apron effected by dropping a worm out of gear with its wheel, and the driving pressure of the worm when engaged is taken upon a ball thrust, which reduces the strain on the feed wheels and the wear correspondingly. On the feed shaft is mounted a slipping clutch, which ensures the safety of the gearing in the event of any portion of the mechanism becoming obstructed, and, in addition, the device serves as a telltale as to whether the operator is working the machine up to the full capacity, at which point the clutch will commence to slip. For the belt drive of the head, a motor drive may be substituted, and, owing to the large range of speeds of the all-gear type of headstock, a simple constant-speed motor can be adopted, thus avoiding the use of the more complicated variable-speed type of motor, which is generally less econ |

|

1911 Pollock and MacNab, Ltd.-Boring & Surfacing Lathe

1911 Pollock and MacNab, Ltd.-Boring & Surfacing Lathe

|

|

|

|