|

Title: |

1911 Article-Thomas Shanks & Co., Quadruple Geared Double Bed Lathe |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V1, 1911, pgs. 30-32 |

|

Insert Date: |

3/30/2020 9:53:26 PM |

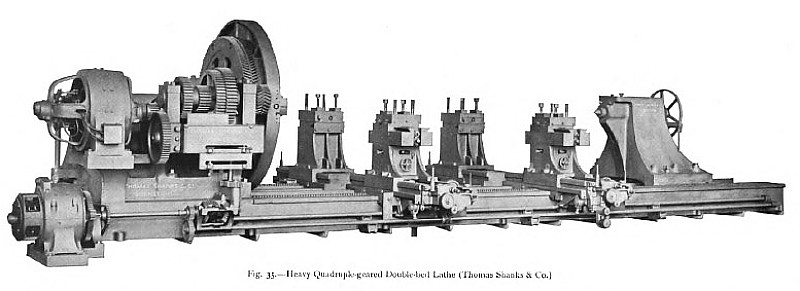

As a final example of the sliding, surfacing, and screw-cutting type of lathe, in which the work is rotated between centres, an illustration is given in fig. 35 of a heavy quadruple-geared double- bed lathe built by Messrs. Thomas Shanks & Co., of Johnstone, who devote themselves more particularly to the construction of machine tools of the heaviest classes. The machine illustrated is intended for heavy-duty work on crank shafts, steel ingots, gun forgings, high-pressure turbine rotors, and general work of a heavy description. Seven different sizes of machines, ranging from 28 to 75 in. height of centres, are made; but larger machines, capable of dealing with work of 18 ft. diameter, are also constructed; and by the use of special packing blocks the capacities of the various machines can be increased. For low-pressure turbine work, much larger machines of the same type are built.

It will be seen from the illustration that the double-slide bed is of great width and depth. It is fitted with very accurate steel guide screws and machine-cut racks.

The fast headstock is of massive design, and the proportions of the forged-steel spindle and the bearings are ample for the heaviest requirements of the lathe. Smooth and silent running and freedom from torsion are ensured by the simplicity and direct ness of the driving arrangements, which are the subject of special patents.

As already stated, the head is quadruple-geared, and the various changes can be readily made by operating the hand lever at the front of the head. On the back of the face plate there is mounted a large-diameter driving wheel the teeth of which are machine-cut. These teeth are usually of the straight type; but, when specially desired, double helical teeth are provided as shown in the illustration.

There are undoubted advantages in the system of direct driving by means of belts, provided the width, thickness, and velocity of the belt are amply sufficient to deal with the heavy cuts and speeds required, and provided arrangements are made for maintaining the correct tension of the belt. In many cases, however, it is desirable to drive the machine by means of a constant-speed, or, if preferred, a variable- speed, electric motor, either direct-connected or through a belt. The illustration shows the machine driven by two direct -connected motors, one of which serves for the feed motions, and the other for rotating the face plate.

Two or more saddles can be mounted upon the beds according to the requirements of the work. Sliding and screw-cutting motions are communicated to each of the saddles through long disengaging gun-metal nuts, and the quick -power movement in either direction is obtained through the machine-cut racks already referred to. In addition, there is provided a hand rack-adjustment. The front saddles have self-acting surfacing rests and compound swivel-slides, while the back saddles have self-acting surfacing rests and top slides specially designed to resist the upward lifting force of the cut. The base of the loose headstock is very wide, and means are provided for accurately adjusting the alignment. It is fitted with a large steel spindle and centre, and with clamping details of a special design. With the exception of the two smallest sizes, the tailstocks of the various machines are moved by power.

The general design and construction of the machine are such that the work is turned truly circular, even under the heaviest cuts, and the arrangement of the saddles and the tailstock is such that work of very small diameter can be turned, and that pieces of exceptionally short length can be machined between centres without necessitating any undue overhang of the loose-head spindle. |

|

1911 Thomas Shanks & Co., Quadruple Geared Double Bed Lathe

1911 Thomas Shanks & Co., Quadruple Geared Double Bed Lathe

|

|