|

Title: |

1886 Article-S. A. Woods Machine Co., Joslin's Circular Resawing Machine |

|

Source: |

Manufacture & Builder, V18, May 1886, pg. 97 |

|

Insert Date: |

11/7/2019 9:10:14 PM |

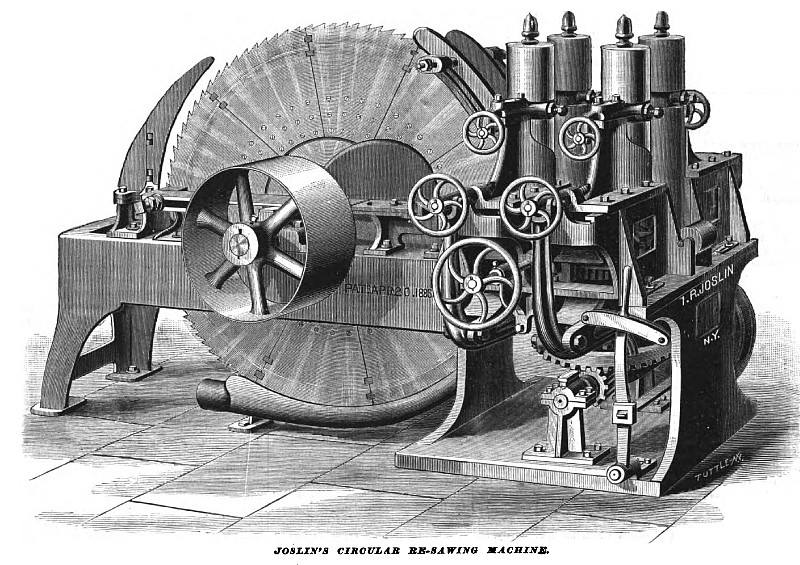

Joslin's Circular Re-Sawing Machine.

We have lately had the opportunity of examining the construction and witnessing the operation of the circular re-sawing machine shown in the accompanying engraving. It has been designed and patented by Mr. I. R. Joslin, of the S. A. Woods Machine Co., 91 Liberty street, New York, and, while retaining the general features common to this class of wood-working machines, embodies a number of original features of pronounced merit, which render it notably simple, strong and compact in construction, convenient to run and operate, and highly efficient in performance. In brief, the net result of Mr. Joslin's improvements has been the production of a machine, which, in the admirable manner in which it meets every essential requirement, stands in the front rank among machines of its class.

The special features of superiority here referred to, reside in the simplification and substantial improvement of the feed mechanism, by which the roils are made accurately self-centering and capable of every form of adjustment, either jointly or independently, sis the requirements of the work may demand, and by which the lumber is presented to the saw in the most advantageous manner and under better control, throwing less strain upon the sides of the saw, and permitting, as a consequence, the use of a saw of lighter gauge than has hitherto been found practicable, and hence making a decided saving in saw kerf, at the time we witnessed the operation of this saw it was working on box lumber 12 to 14 inches in width, making less than 1/16-inch kerf, and in the adoption of a greatly improved mechanism by which the forward and backward feed is operated with a single belt and with one lever.

The principal features of construction will be understood from the following description: The frame is cast in two pieces, which are bolted together in such a manner that they may readily be taken apart for convenience in shipping where a saving of space may be desirable. As to the feed works, these are made heavy and strong, and the working parts compactly and conveniently disposed, so that all movements and adjustments shall be readily commanded by the operator. The guides for the roll stands, it will be observed, are brought well up to the central point of the board to be sawed, giving a free action of the slides in opening and closing the rolls, and insuring an equable pressure on the whole width of the board and allowing the rolls to work perfectly on lumber of unequal thickness.

The mechanism by means of which the movements and adjustments of the feed rolls are controlled are simple and effective. The rolls are connected together with arms having what the inventor terms "equalizing bars" and bell cranks, each pair being independent in action, and provided with independent means of adjustment. When connected up with the equalizing bars the rolls are accurately self-centering. By disconnecting the long arm from the roll stand and equalizing bar, and bolting the bar fast to the sliding plate, the operator may hold the rolls on one side rigid in any desired position for slabbing from the side of a board. For this work, the handwheels shown on both sides of the machine are called into play to adjust the rolls independently of each other in the desired position, the large hand wheel seen on the left enabling the operator to move the feed works bodily across the machine. Thus, it will be seen, these joint and separate movements and adjustments of the rolls are so complete and perfect as to provide for every requirement that may be thrown upon them.

A feature of special merit, furthermore, is the method by winch the forward and backward feed is obtained by the use of a single belt and the lever seen on the left of the machine. The mechanism by which this is affected is in the form of a clutch engaging: or disengaging appropriately disposed gearing. It is simple, strong and durable, and not liable to become disarranged.

It will be observed, likewise, that the frame of the machine is so designed that the operator may approach close to the saw blade to file and set the saw when needful, without requiring him to climb on top of the frame to reach it.

The machine is built in the best manner, all shafts are of steel, and the saw flange is of hammered steel, to ensure proper stiffness and at the same time allow of a thin flange. The machine is furnished with either a segment blade, as shown in our illustration, or with a solid saw, and with either solid or inserted teeth, as the user may prefer. The inserted teeth are made as light as 17 gauge, and the solid teeth as light as 21 gauge, though the makers recommend for rough hard work a saw of 19 gauge.

Four sizes of this machine are built, which differ only in the size of saw and weight of machine. The sizes are:

60 inches diameter, cutting 26 inches wide.

56 inches diameter, cutting 24 inches wide.

50 inches diameter, cutting 21 inches wide.

46 inches diameter, cutting 19 inches wide.

The machine, in its present form, embodies the results of a long experience with this class of machinery, and the makers confidently claim for it that it is capable of turning out a large amount of work of the very best character; that it makes a notable saving in saw-kerf, since its construction permits of the use of a lighter gauge saw than has heretofore been found possible on other machines of its class using circulars; and that it is capable of performing satisfactorily the work of re-sawing lumber of almost every description, from picture-backing to the heaviest lumber that can be handled on a machine of its class. We commend it to the attention of mill men.

For further particulars and detailed description, address the S. A. Woods Machine Company, 91 Liberty street, New York; 172 High street, Boston, or 61 South Canal street, Chicago.

US Patent: 340,444

http://datamp.org/patents/displayPatent.php?number=340444&typeCode=0 |

|

1886 S. A. Woods Machine Co., Joslin's Circular Resawing Machine

1886 S. A. Woods Machine Co., Joslin's Circular Resawing Machine

|

|