|

Title: |

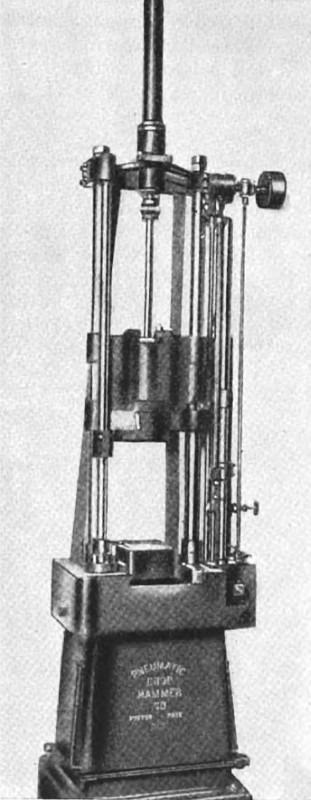

1927 Article-Pneumatic Drop Hammer Co., Drop Hammer |

|

Source: |

American Machinist, V67, 29 Sept 1927, pg. 521 |

|

Insert Date: |

2/12/2019 12:01:10 PM |

An improved type of air-lift, gravity drop hammer, which is a development of the hammer illustrated and described on page 179, Vol. 62, of the American Machinist, is being put out by the Pneumatic Drop Hammer Co., 261 Franklin St., Boston, Mass. The head of this hammer is lifted by air pressure in a cylinder mounted vertically on a tie-bar at the top of the columns in line with the travel. The blow is delivered by the falling weight of the head, unassisted by air pressure, but the force of the blow may be adjusted to any desired amount within the capacity of the machine by adjusting the control valves to give a cushioning effect. This adjustment is made by the single movement of a lever which may be moved at will by the operator to strike light and heavy blows alternately or locked in one position to repeat blows of any desired force indefinitely.

The head slides upon two round columns of steel which are ground accurately to size and parallelism. Two bronze bushings on each side of the head encircle the round columns and provide ample wearing surface to guide the falling head without undue friction yet confine it against looseness and tendency to shake when the blow is delivered.

The head is released to strike the blow by a safety device, entirely pneumatic, which will not permit the release to occur while either of the operator's hands are in the danger zone; or it may be released by a treadle. The valves may be set to operate the head continuously while the treadle remains depressed, or to deliver one blow, only, at each depression of the treadle.

A quickly made adjustment of the safety device renders the treadle inoperative when desired so that the dies may be adjusted or removed without danger of the hammer head falling by reason of accidental depression. The valves are so constructed that the head cannot fall because of failure of the air pressure, or even because of breakage of the supply pipe.

The height of drop may be regulated to any distance within the capacity of the machine, and the valves set automatically to cushion the blow to any desired extent. The head is ordinarily held up by air that is trapped in the cylinder, but a mechanical safety dog is provided to engage and hold it up while changing or adjusting the dies.

The advantages claimed for the hammer are: that it is self-contained and can be set up anywhere without reference to belts, shafts or other power transmitting devices; that it is rapid in action because of the fact that the head is picked up instantly on the rebound by the air cylinder and there is no loss of time, or "shivering" in the return stroke; and that it so simple in construction and operation that it may be operated by unskilled men.

It is made in all sizes from 50 lb. up. The anvils are ordinarily made to weight fifteen times as much as the heads, but may be made in 20-to-1 ratio for special work, if desired. A steel insert in the anvil secures the lower die. |

|

1927 Pneumatic Drop Hammer Co., Drop Hammer

1927 Pneumatic Drop Hammer Co., Drop Hammer

|

|