|

Title: |

1915 Article-Greene, Tweed & Co., Rochester Automatic Lubricator |

|

Source: |

Practical Engineer, V25, 01 Sept 1915, pg. 852 |

|

Insert Date: |

12/14/2018 1:26:26 PM |

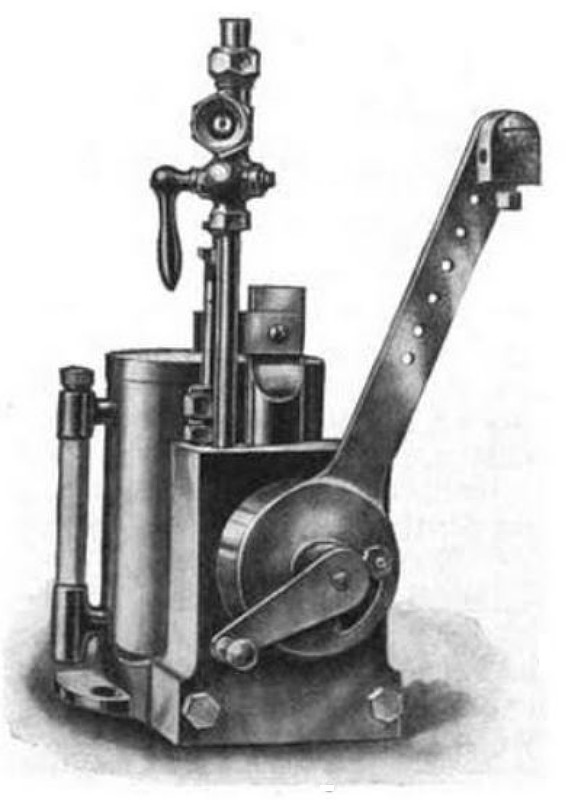

The New Rochester Automatic Lubricator

After successful tests covering more than a year on one engine running at 800 r.p.m. and another at 275 r.p.m., Greene, Tweed & Co. announces The New Rochester Automatic Lubricator, Fig. 1, embodying some of the most important improvements ever made in that well-known lubricator during its 20 yr. service in power plants.

Innovations make considerable change in the appearance of the Rochester. First, as seen in the illustration the familiar pawl and ratchet is replaced by a clutch drive, and this drive is perhaps the chief improvement. It does away with the noise of the pawl, which is objectionable in plants where quiet running, high speed engines are in use, giving a noiseless lubricator and positive lubrication. Notwithstanding that it is a clutch drive, there is a regulating device, whereby more or less lost motion can be given to the actuating arm, by changing the position of the adjustment pin in that arm.

Also, the stuffing box is made stronger and larger, permitting the use of more Palmetto packing, insuring tight stuffing boxes and smooth-running pistons.

Every lubricator user who has experienced the breaking of a lubricator gage glass and the consequent spilling of the oil from the bowl all over the floor, will appreciate the automatic gage glass fixture on the New Rochester. If the gage glass breaks, a valve in the lower fixture automatically shuts off the oil and the lubricator keeps on just as if nothing had happened.

The principal working parts are encased and protected from dirt and grit, yet all parts are easily get-at-able. All mechanism is compactly centered in a steel pump block, which can be almost instantly detached from the bowl or reservoir, giving easy access to all working parts for cleaning or repairing, without disturbing the reservoir attached to the engine. Figure 2 shows the New Rochester being inspected at the end of a year's test in the Union Brewing Co.'s plant at Newark. Attached to a Ridgway high speed engine of 75 kw. output, the New Rochester has stood up under a year's run producing no noise in the running. Neither is there sign of wear or slippage. Chief Engineer, Frank J. Sturgis of the plant says: “The New Rochester has worked noiselessly and the new clutch drive is absolutely positive. The stuffing-box prevents leakage and the lubricator has saved 75 per cent in oil. The New Rochester is everything that a lubricator ought to be.”

Close regulation of feed is a sterling feature of the Rochester and 3 ways of adjustment are offered, any one of which insures perfect regulation. These ways are: By changing the position of the adjustment pin in the actuating arm; by adjusting the screw in the plunger; and by changing the position of the rod connection on the actuating arm. Once adjusted to feed any amount of oil from the tiniest drop to an almost continuous stream, it feeds that amount steadily for any pressure, vacuum or temperature. No working pressure can overcome the constant feed because the internal design of the Rochester is mechanically right. Each independent feed is equipped with an improved vacuum and check valve, so they are unaffected by any vacuum in the cylinder that might otherwise syphon the oil from the oil line. Each feed of every New Rochester is also equipped with a Multiplus sight feed, which is a combination of the 3-way cock, as formerly furnished with Rochester lubricators, and a patent sight feed device. The 3-way cock shows the size and number of drops discharged by the pump. The sight feed shows the movement of the oil as it passes to the point of delivery.

The sight feed is constructed so that the oil passes through a circular chamber enclosed by a heavy glass disk. The outlet in the center of this chamber contains a hollow plug or plunger and to pass through this outlet the oil must compress the plunger, which moves in and out, flashing or blinking exactly according to the pulsations of the pump, showing plainly the movement of the oil being delivered as it passes the sight glass to its destination and while it is in a solid column under pressure.

In appearance, the New Rochester is ornamental to pump, compressor or engine.

Perfect lubrication is secondary to the great economy in oil consumption that the New Rochester effects as savings as high as 75 per cent have been recorded with this lubricator. |

|

1915 Greene, Tweed & Co., Rochester Automatic Lubricator

1915 Greene, Tweed & Co., Rochester Automatic Lubricator

1915 Greene, Tweed & Co., Inspecting the Rochester Automatic Lubricator

1915 Greene, Tweed & Co., Inspecting the Rochester Automatic Lubricator

|

|