|

Title: |

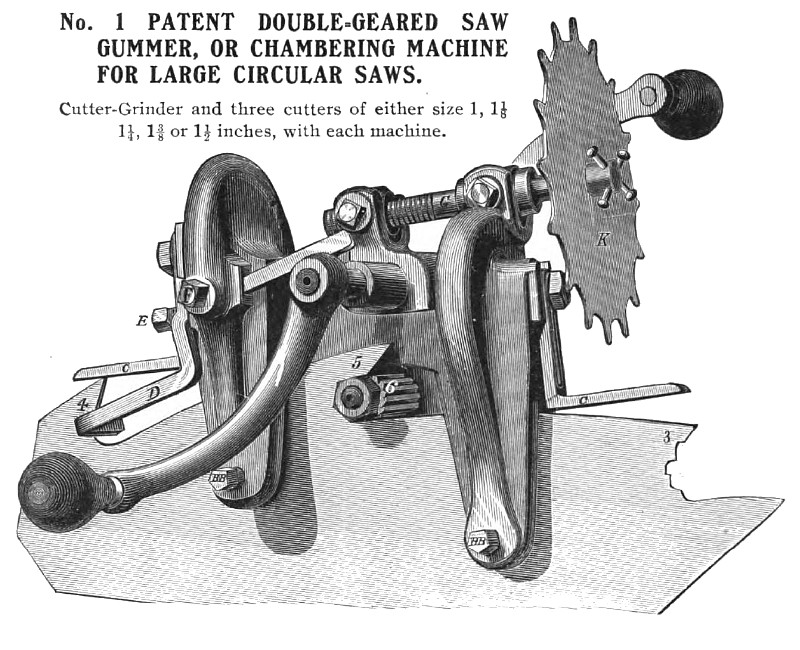

1912 Article-Henry Disston & Sons, #1 Patent Double-Geared Saw Gummer |

|

Source: |

Disston's Lumberman Handbook, 1912, pg. 46 & 47 |

|

Insert Date: |

11/29/2018 8:47:19 PM |

Before using the gummer see that the oil holes are clear. A few drops of oil will be sufficient for from three to five hours' use. After using the gummer remove the chips or turnings that accumulate back of the cutter. If allowed to remain they will cause trouble by getting into the working parts of the machine. Run the cutter back by means of screw G as far as necessary. Then place the machine on the saw, with the cutter close up in the chamber of the tooth to be gummed.

If the teeth are regular and the same distance apart, start the cutter in any chamber; but if they are irregular, make them even by commencing in the smallest tooth. After gumming the saw a few times the teeth must become regular. E is a set screw to regulate the depth of gullet. Fasten the machine to the saw by means of the screw BB, and proceed to gum the first tooth, one of the points of the star being struck at each revolution by a projection on the handle the cutter is steadily fed in until arrested by set screw E. Remove the machine to the next tooth, after having run the cutter back and proceed as before until all the teeth are gummed. Should the gullet or chamber be worn smooth, and the cutter fail to bite, rough the gullet with a file. The cutter is so arranged as to slide on its axis, and when one portion becomes dull, by removing a washer from back to front, a new sharp cutting surface will be presented, so continuing to change the washers until the whole face of the cutter becomes dull.

To take the cutter off the shaft, put the pin, hanging to the gummer, in the hole in the ratchet wheel, to keep the shaft from turning while unscrewing the nut, which has a left-hand thread. The hand wheel on end of feed screw, outside of the star, is to allow the operator to feed easily and gently with the hand when starting in to cut rough gullets, until the cutter gets a bearing, when by tightening the jam-nut on opposite side of star, the machine is made self-feeding. The rachet by which the cutter is moved, effectually prevents any back motion, which has hitherto been a serious objection.

To grind the cutters the stone should have a perfectly straight face and turn from the operator. Lower the adjustable frame of grinder until the cutter touches the stone, then adjust spring in proper position. When properly adjusted, the backs of teeth of cutters can be ground so the cutting edge will be a little the highest and the cutters round and sharp. Furnished with either No. 1, 2 or 3 (Pin) shaft. |

|

1912 Henry Disston & Sons, #1 Patent Double-Geared Saw Gummer

1912 Henry Disston & Sons, #1 Patent Double-Geared Saw Gummer

1912 Henry Disston & Sons, #1 Patent Double-Geared Saw Gummer Cutter Holder

1912 Henry Disston & Sons, #1 Patent Double-Geared Saw Gummer Cutter Holder

|

|