|

Title: |

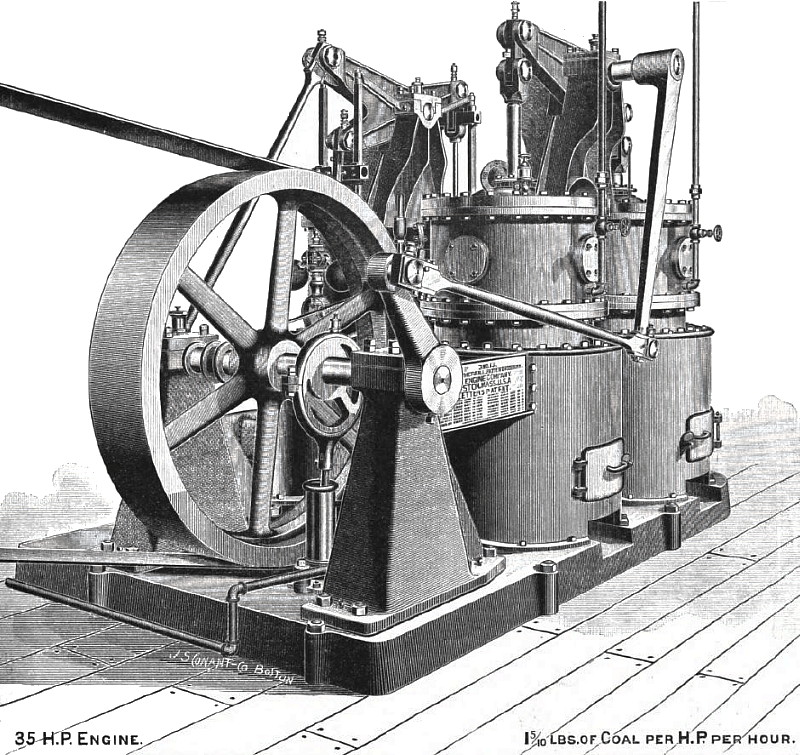

1889 Article-Woodbury, Merrill, Patten and Woodbury Air Engine Co., 35 H.P. Hot Air Engine |

|

Source: |

American Engineer, V18, 25 Sept 1889, pg. 109 |

|

Insert Date: |

10/22/2018 8:43:07 PM |

The engine is constructed with two operating or “working” cylinders, and two other cylinders called “reversers;” each reverser is provided with a reverser heater, placed within a furnace; a regenerator, consisting of wire cloth of large, superficial area, extending from the cooler to the bottom of the reverser heater; a cooler, consisting of a large number of thin, copper tubes surrounded by water, and a displacer piston, having metallic packing rings, and adapted to reciprocate within the cooler. Each working cylinder is provided with a working piston having metallic packing rings. Each reverser is connected by means of pipes with the working cylinders as follows: The hot chamber below the displacer piston is connected with the bottom of the working cylinder directly opposite, and the cold chamber above the displacer piston is connected with the top of the working cylinder diagonally opposite. The means employed of converting the reciprocating motion of the pistons into a rotating motion are all of the common type. A small single acting air pump, having a leather packed piston, is operated by an eccentric fastened to the main shaft. The pump is used to compress the air to the initial pressure required, and to maintain this pressure, which is subjected to a loss by leakage around the piston rods. The regulation of the speed is obtained in a simple manner by the adaptation of a common centrifugal governor. The power produced is due to the energy exerted upon the working pistons by the alternate raising and lowering of the temperature of the same mass of air within the reversers. When sufficient heat has been imparted to the reverser heaters, by the combustion of any kind of fuel within the reverser furnaces, the engine may be started by the use of the compressed air (previously compressed into a small reservoir) admitted into the engine in an alternate manner, similar to the starting of a Corliss engine, by means of starting valves.

The cooling medium used is any kind of water, or a blast of air circulated through the coolers. A very small quantity of water is required, and the same water may be used over and over again. This improved air engine is not an exhausting engine, like the steam engine. It uses the same mass of air over and over again, simply expanding and contracting it by alternate heating and cooling, and thus generates a power in accordance with the well known laws of the expansion of gases, which power is developed by the working cylinders. It has neither admission nor exhaust valves, and its motion is as regular and uniform as the best steam engines. It is an absolutely safe power producer, and there is no possible danger from explosions or ruptures. It will run as long as it is fed with fuel, and when the fire goes out will stop. That is all the danger there is to it.

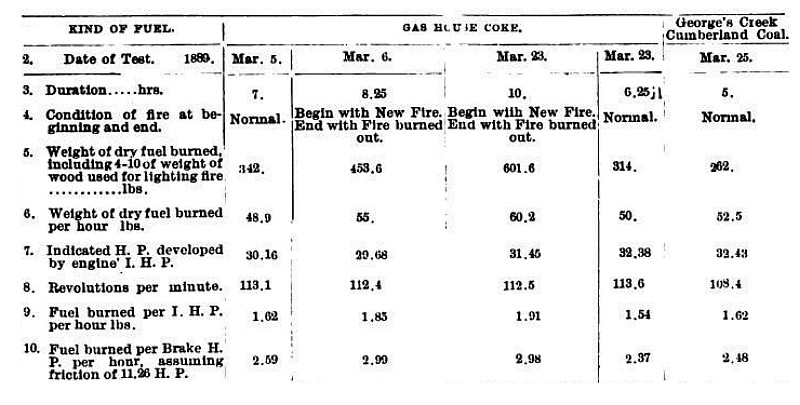

The accompanying engraving is an elevation of No. 13 Air Engine, in operation at the works of the Downer Kerosene Oil Company, West First Street, South Boston. Mass. Recently a series of tests were made by George H. Barrus, M. E., to determine the economy as to consumption of fuel with which the engine works. The following is a brief summary of the principal results. “On all the tests except the last, the principal load on the engine consisted of a No. 35 Sturtevant Exhausting Fan, with 72-inch case which makes 535 revolutions per minute when the engine makes 110 revolutions per minute. On the last test, the principal load consisted of the same fan, and in addition, a Sturtevant Fan, with 60-inch case, No. 123, which made about 625 revolutions per minute. The friction of the engine was determined by subtracting the average power absorbed by a Prony Brake, applied to the fly-wheel, from the indicated horse power developed at the same time, on the occasion of supplementary tests, a part of which were made March 7th, and a part, March 22nd, the number of these tests being fourteen. The average Indicated Horse Power was 31-18 and the average Brake horse power, 19.92.”

“It appears from the table, taking the test of March 23rd as a proper indication of the performance of the engine, that the amount of coke used in a ten hours run, including the wood and coke required to start the fire, beginning with a cold engine, was 1.91 lbs. per indicated horse power per hour, and 2.98 lbs. per brake horse power per hour. On the same test, for a period of 64 hours, after the engine had attained its normal conditions of work, the quantity of coke consumed was 1:54 lbs. per indicated horse power per hour, and 2.37 lbs. per Brake horse power per hour. During the test of March 6th, the quantity of water which passed through the coolers amounted to an average of 3612 lbs. per hour, which is equivalent to 7.2 gallons per minute. This water was supplied at a temperature of 36 degrees, and discharged at a temperature of 102.8 degrees.” “I do not regard these results as the best that can be obtained from the engine, for there is a considerable loss of heat from the unprotected exterior surface of the furnaces, due to radiation, which can easily be prevented by the use of suitable covering.” “Taking the results as they stand, however, the consumption of fuel per effective horse power transmitted through the belt, is not more than one-half of that required for the best non-condensing steam engines of small power, which are commonly used.”

The inventors of this engine are Messrs. Jas. A. Woodbury, Joshua Merrill, George Patten and Edward F. Woodbury of Boston and foe more than 35 years, these gentlemen, or some of them, have been engaged in its projection, so to speak. They were the first Americans to patent an air engine in this country or in Europe, their first patent being dated 1853. Further information may be obtained from Joshua Merrill, treasurer of the Woodbury, Merrill, Patten & Woodbury Air Engine Company, 8 Exchange Place, Boston, Mass. |

|

1889 Woodbury, Merrill, Patten and Woodbury Air Engine Co., 35 H.P. Hot Air Engine

1889 Woodbury, Merrill, Patten and Woodbury Air Engine Co., 35 H.P. Hot Air Engine

1889 Woodbury, Merrill, Patten and Woodbury Air Engine Co., 35 H.P. Hot Air Engine (Specifications)

1889 Woodbury, Merrill, Patten and Woodbury Air Engine Co., 35 H.P. Hot Air Engine (Specifications)

|

|