|

Title: |

1889 Article-Providence Steam Engine Co., Greene Steam Engine |

|

Source: |

American Engineer, V18, 14 Aug 1889, pg. 55 |

|

Insert Date: |

10/14/2018 9:22:40 PM |

|

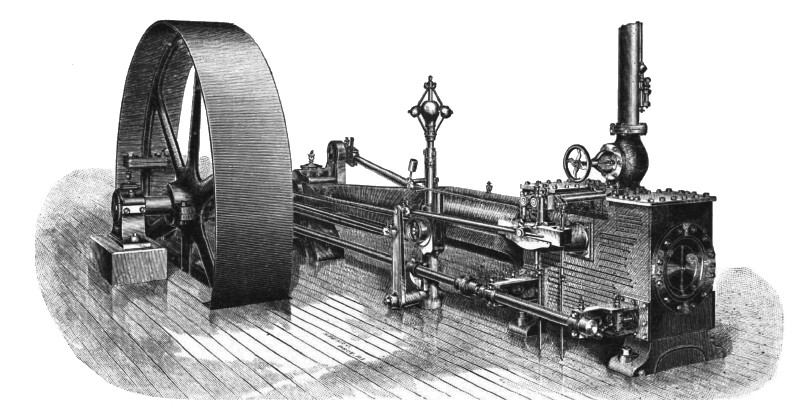

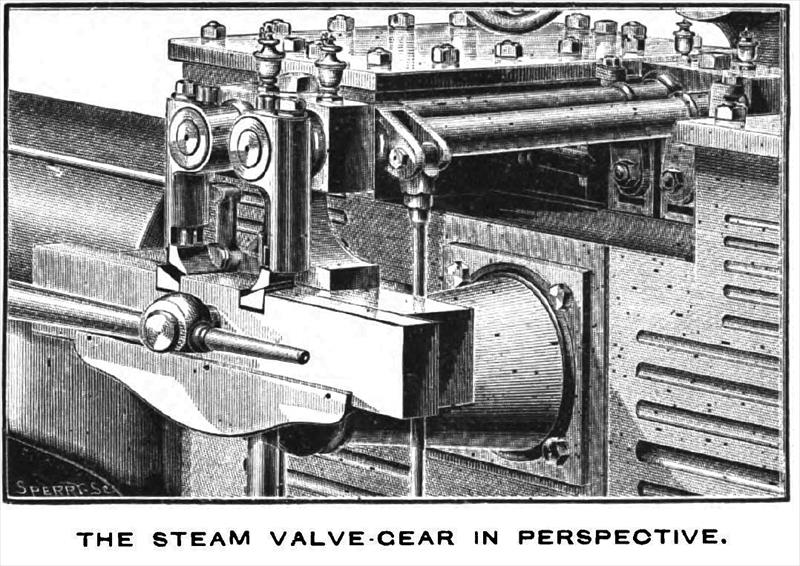

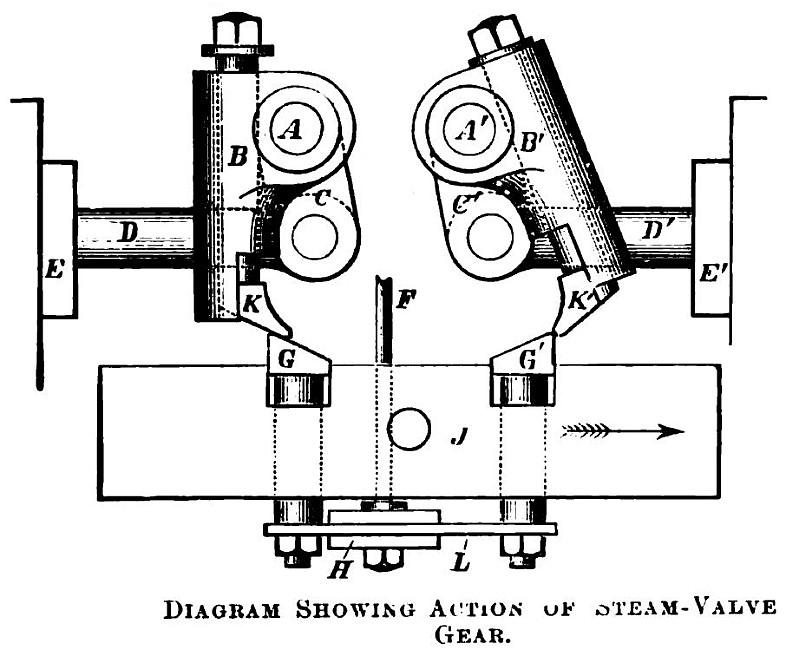

The accompanying engravings illustrate a horizontal automatic cut-off steam engine constructed only by the Providence Steam Engine Company, of Providence, R. I. The engine has been known for several years as one differing in design from any other. It has flat slide-valves, both steam and exhaust, a steam closing mechanism and a safety stop on the regulator. From time to time, it has received such additions, changes and modifications as appeared desirable for appearance, strength, proportion and a more efficient operation, until it has reached a form and arrangement that seem to admit of no further improvement. The excellent workmanship and good finish reflect great credit upon the makers. It is especially known as an engine that has the only liberating valve gear, without spring, catch, or wedge, thus removing all strain upon the governor while tripping the valves. The bed-plate is of the girder pattern, symmetrical in appearance, and of ample strength. The slides are cast separate and secured to bedplate by dowels and bolts. The main journal boxes are made in four pieces and provided with set screws and check nuts which permit of convenient and accurate adjustment. The governor is of the “Porter” pattern and is driven by a flat belt from the main shaft. The valve gear is detachable and is so controlled by the governor that the cutting off may be affected from zero to three-quarters of the entire stroke. The valves are four in number– two steam and two exhaust—and are of the flat-slide pattern. The power which moves them is applied parallel to, and in line with their seats, so that they cannot rock or twist —thus obviating the tendency to wear unevenly. The steam-valves when tripped are shut by a combined action of a weight and the pressure of the steam on the large valve-stems, thereby insuring a quick cut-off, and the positive closing of the port, under all circumstances of speed and pressure. The steam valves are operated by toes, on the inner ends of two rock-shafts that connect with the valve-stems outside the steam chest. The outer ends of the rock-shafts are furnished with steel tipped toes. There is a sliding bar carrying tappets, which receives a reciprocating rectilinear motion from an eccentric on the main shaft. Below the sliding bar is a gauge-plate connected with the governor, which receives an up and down motion from a reverse action of the governor balls. The tappets in the sliding bar are attached to the gauge-plate and elevated or depressed in the bar by the action of the governor. As the sliding bar moves in the direction of the arrow, one of the tappets is brought in contact with the inner face of the toe on the rock lever, causing it to turn on its axis, thereby opening the steam-valve at one end of the cylinder. At the same moment, the other tappet comes in contact with the outer face of the other toe and as the surfaces are beveled, the toe is forced up into the socket until the tappet passes under, when it drops by gravity alone into its original position to be operated upon in its turn, when the motion of the sliding bar is reversed. As a result of this motion, the tappets always give the valves the same lead and as the bar moves in a straight line, while the toe describes the arc of a circle, the tappet will pass by and liberate the toe, which is brought back to its original position by a weight, and the steam pressure on the large valve-stem, which thus closes the valve and cuts off the steam. The liberation of the toes will take place sooner or later according to the elevation of the tappets; that is, the lower the tappets are, the sooner the toes will be liberated, and vice versa. By the elevation or depression of the gauge-plate, the period of closing the valves is changed, while the period of opening them remains the same. The adjustment of the gauge-plate is affected directly by the governor. Both the exhaust-valves and seats are convenient of access and removable from the outside of the cylinder. The valves receive their motion from a separate eccentric, thus allowing of easy adjustment, without interference with the steam-valve mechanism. All the connections are on the outside, are few in number and have ample bearing surfaces insuring freedom from rapid wear and derangement. A safety stop-motion is combined with the governor, preventing the admission of steam should the governor belt run off or break. The cross-head gibs are directly opposite the centre of pin, thus avoiding any cross strain upon the piston rod: aa lack of attention to the point has been the cause of many serious accidents. The steam-ports are large, thus insuring the full pressure of steam to the point of cut-off. The engine is extremely sensitive to the action of the governor and is, therefore, particularly adapted to those situations where perfect regulation is required. All parts are well proportioned, made of the best material, accurately fitted, and highly finished, A A' are the two rock levers; BB the sockets attached to them and within which the toes R K are contained; C C’ the arm of the levers attached to valve-stems; D D' the valve-stems; E E the steam-chest; F the governor-rod; G G" the tappets; L the gauge-plate; H the gauge-plate guide, and J the sliding bar. The sliding bar J is shown moving in the direction of the arrow, causing the tappet G' to operate upon the toe K’, giving an opening movement to the valve-stem D', the tappet G meanwhile passing under and lifting the toe K. The amount of opening of steam-valves is determined by the height of the tappets G G', the positions of which are always under control of the governor. The toes drop by gravity, no springs being used, thus relieving the governor of all strain while tripping. The Providence Steam Engine Company has patterns on hand 1 or engines from 15 to 1200 horse-power. From a list of numerous recent orders, we note that the company is constructing for the West Side Cable Railway, Chicago, two engines of 1200 h.p. each. |

|

1889 Providence Steam Engine Co., Greene Steam Engine

1889 Providence Steam Engine Co., Greene Steam Engine

1889 Providence Steam Engine Co.-Greene Steam Engine (Valve Gear)

1889 Providence Steam Engine Co.-Greene Steam Engine (Valve Gear)

1889 Providence Steam Engine Co.-Greene Steam Engine (Valve Gear)

1889 Providence Steam Engine Co.-Greene Steam Engine (Valve Gear)

|

|