|

Title: |

1865 Article-L. D. Fay, Combined Screw Lathe & Milling Machine |

|

Source: |

Scientific American, V13, 25 Nov, 1865, pg. 335 |

|

Insert Date: |

1/4/2018 10:56:09 PM |

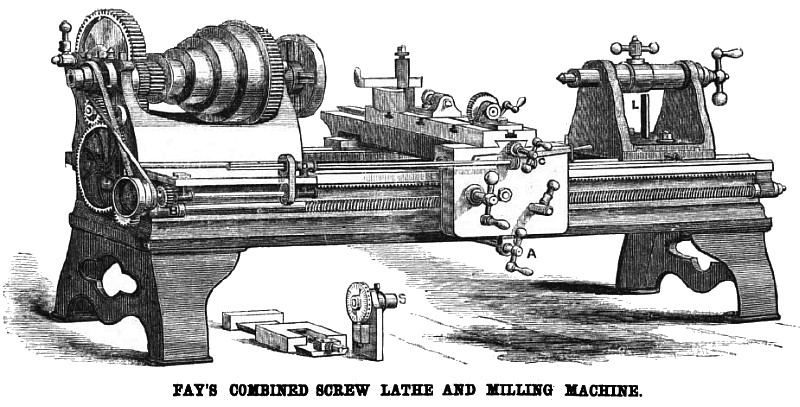

Combined Screw Lathe and Milling Machine.

A noticeable feature in modern American workshop machinery is the several uses to which the same tool can be applied. Time was when a lathe was merely a rude affair for making an object round, but it has been vastly improved upon by the efforts of ingenious men, and the different attachments which have been made to it render it one of the most indispensable tools.

The lathe here illustrated is a strong and well-designed machine: it swings 28 inches, and is a screw-cutting and milling machine combined; besides this it can be used for a variety of purposes, such as boring, that other lathes are not well adapted to.

A novel feature in this lathe is the addition of cross-feed. This is a most important advantage on some kinds of work, as it is done more expeditiously than by hand, and of a much better quality. The arrangement can be seen in the engraving where the feed screw shaft has a small pinion cut on it, in which a worm runs; the worm is driven by a small countershaft and belt on the shears near the cone pulleys. This arrangement can be easily detached and thrown out of gear by removing the box, D, and releasing the thumb screw, C. The carriage and slide rest is raised or lowered so as to adjust work thereon by the handle, A, which works a vertical screw by bevel gears on the back of the lathe.

The variety of work for which this lathe is adapted Is as follows:—It may be used as a common turning and screw-cutting engine lathe, with the advantage of a cross-feed, which is not usually obtained with lathes of this size. It may be used as a boring engine. The work can be easily fastened to the table and afterward adjusted perpendicularly or laterally with the same facility as in the improved boring engines now in use in the best shops. It is eminently adapted for use as a heavy milling machine. One of its merits, in this respect, is the facility with which it can be adjusted perpendicularly, enabling the workman to make two or more cuts upon any piece and then return the lathe to exactly its first position, ready for the first cut on another piece by simply turning one handle. The machines have been used during the past year for working pieces of wrought iron and steel of larger dimensions than are commonly worked in milling machines, doing the work quicker and getting a smoother surface than by the planer. It may be used as a gear cutter for any size within its range, for the making of reamers and cutters, fluting of taps, slabbing of bolt heads, etc. For cutting bevel gears the spindle, S, has a joint attached capable of adjustment at any angle.

For further particulars, address L. D. Fay, Worcester, Mass. |

|

1865 L. D. Fay, Combined Screw Lathe & Milling Machine

1865 L. D. Fay, Combined Screw Lathe & Milling Machine

|

|