|

Title: |

1908 Article-Buffalo Foundry & Machine Co.-Combined Steam Drop Hammer |

|

Source: |

Southern Machinery, V8, Nov 1908, pg. 13 |

|

Insert Date: |

10/28/2017 9:48:41 PM |

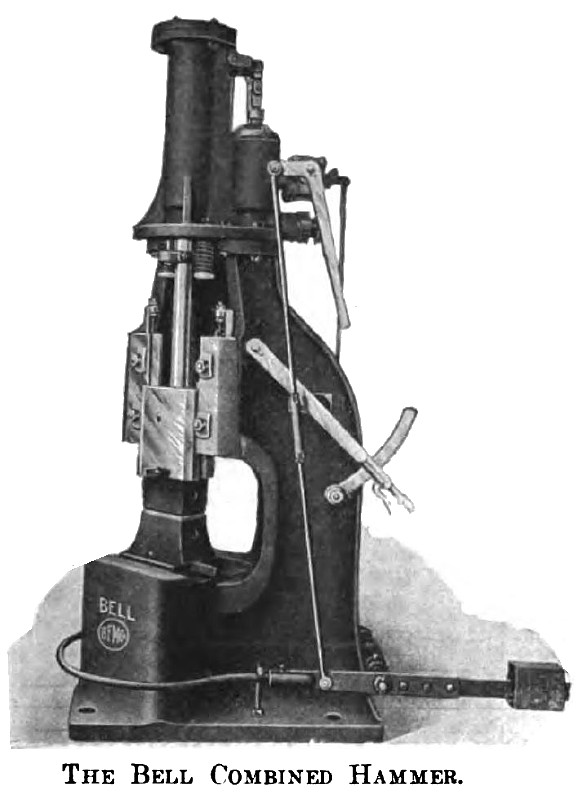

A BELL STEAM HAMMER FOR GENERAL WORK.

ONE of the designs of steam drop hammer manufactured by the Buffalo Foundry & Machine Co., Buffalo, N. Y., is shown in the accompanying illustration. The name of Combined hammer is given this design as it is so built that it is adaptable to light drop forging work, as well as that requiring a guide pattern hammer. The anvil block is cast integral with the main frame, which is of open hearth steel, so that the slides, which are bolted through the frame, have a rigid connection. The manufacturers claim that this construction maintains the dies in perfect alignment at all times so that the hammer may be used with formed dies.

This hammer has a simple and sensitive valve construction, giving the operator perfect control of the blows being struck at all times. The valve mechanism is so constructed that it has a sliding connection with the cylinder, thus eliminating all danger of derangements and breakage from jars struck on the anvil. Steam is admitted either above or below the piston and the hammer may be operated by compressed air, if so desired, without making any change in the valve gear or working conditions.

Cast steel is used for the main frame and it is so proportioned as to overcome all jarring and shearing strains and give a strong, rigid tool. The anvil blocks are set at an angle of 45 degrees, this construction allowing long pieces to be worked either lengthways or crossways as desired. The main frame casting is strongly reinforced where the guides are bolted on, thus insuring the alignment of the dies at all times and under heavy service.

A one-piece casting contains the cylinder and the throttle valve chests, and extra heavy flanges are provided for securing this casting to the main frame. The main valve is of the balanced type, working without friction in a removable cast-iron bushing with port edges finished so as to give sensitive and uniform control.

The hammer head is of hammered steel from one piece and with the V-ways milled therein to fit the ways of the guides, which are secured to the main frame of the casting by through bolts with spring washers. A taper gib for taking up wear is supplied to fit on the guides. The piston rod is fitted into a taper hole in the top of the hammer head and thus securely held. Piston head is forged onto the top end of the piston rod and is a solid steel forging. Steel snap piston rings are provided.

Strong spiral springs are fitted under the reinforced cylinder flange for cushioning the upward stroke and as a protection against careless handling, there being clearance between the top of the piston and the cylinder cover when these springs are compressed solid. An automatic force feed oil pump is provided for lubricating the valves and cylinder when the hammer is being operated.

These combined hammers are built in several sizes for general forging work and each is equipped for both hand and foot operation. The foot treadle is of special design and gives a sensitive control of the hammer, allowing the smith to dispense with the aid of a helper.

This company manufacture two other styles of Bell hammers, the single frame guide and the open frame, in a large number of sizes and equipped for a wide range of work. |

|

1908 Buffalo Foundry & Machine Co.-Combined Steam Drop Hammer

1908 Buffalo Foundry & Machine Co.-Combined Steam Drop Hammer

|

|