|

Title: |

1908 Article-Bethlehem Steel Co., Steam Powered Drop Hammer |

|

Source: |

Southern Machinery, V8, Nov 1908, pg. 3 |

|

Insert Date: |

10/26/2017 1:18:46 PM |

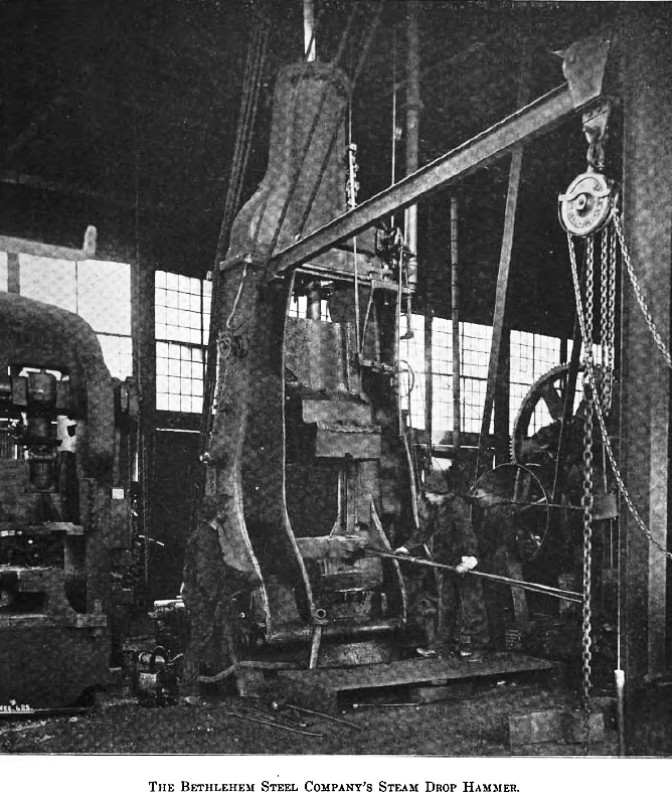

BETHLEHEM STEAM DROP HAMMER

The ordinary drop hammer is made practically through-out of cast-iron and is too light for the hard service required. In the forge shop of the Bethlehem Steel Co., South Bethlehem, Pa., hammers failed so seriously that they were forced to make improvements in the designs and construction. The ratio between the falling weight and base was increased to 20 to 1, which increased the efficiency and by using open hearth steel, the cracking of the base has been prevented, the sub-base being satisfactorily made of cast-iron.

The bottom of the upright and top of the hammer base are planed flat to give a maximum bearing surface. The alignment of the uprights is maintained by having a sliding-machine fit where the upright extends down the sides of the hammer base, which surface being vertical, prevents the lodgment of scale and consequent wear.

To distribute the side thrusts on the uprights, due to having the forging out of center, they are rigidly connected by heavy tie bolts connecting lugs cast on the base of each upright. This construction prevents any spreading, and minimizes any torque action of the drop.

On the Bethlehem hammer both screw and nut for die hammer base. To make renewals it is only necessary to remove a hard steel plate (serving also to protect the upright), which permits sufficient forward movement to clear the angle on the lug, allowing the bolt and nut to be removed, and new ones inserted.

The hammer is automatic, double acting, and readily operated by hand. The valve gear is simple in construction and design, giving perfect control of the hammer and requires but little attention for adjustment. A piston retarding device, in addition to steel buffer springs, is provided for protecting the cylinder from careless handling. The piston rod glands are made in halves, thus facilitating their removal, and the piston rings may be examined or replaced without removing the ram from the rod. The rod and piston are of high-grade steel, forged in one piece.

Steel uprights are heavy and provided with adjustable guides to take up wear due to the ram, and these may be removed without dismantling the hammer.

Ample bearing is provided for the uprights on the base, and the surfaces are arranged so that the lodgment of scale, with is consequent wear, is prevented. |

|

1908 Bethlehem Steel Co., Steam Powered Drop Hammer

1908 Bethlehem Steel Co., Steam Powered Drop Hammer

|

|