|

Title: |

1908 Article-Beaudry & Co.-Power Hammer |

|

Source: |

Southern Machinery, V8, Nov 1908, pg. 6-7 |

|

Insert Date: |

10/26/2017 12:41:10 PM |

BEAUDRY HAMMER AND FORGING PRESS

The uses and economics of power hammers in blacksmith shops have become well known. It is certain that few shops, large or small, can afford to be without them. Their first cost, the cost of installation and maintenance, is so small that it places them within the reach of all, and even though the power hammer is called upon to serve but one fire, it will so increase the capacity of that fire and reduce the cost of forgings as to repay the first cost within a short time. It is not, as some people suppose, merely a machine for roughing out work, but a tool for producing finished work and will turn it out more perfectly and evenly than could possibly be done by hand, and of course in a small fraction of the time. This is especially true of large, unwieldy pieces.

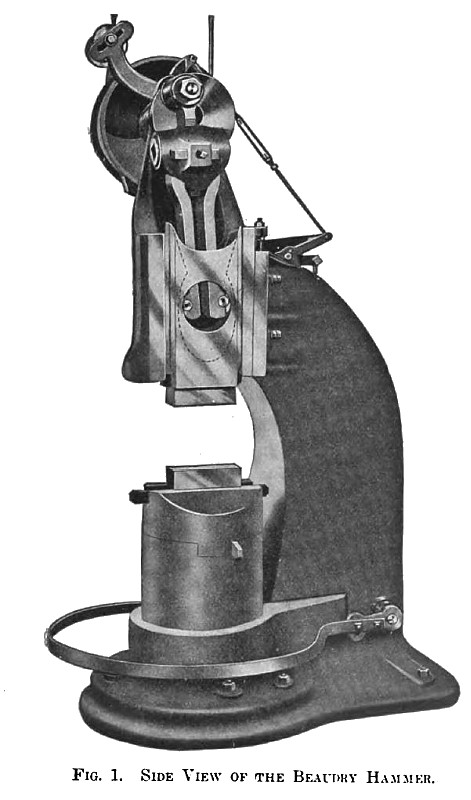

The Beaudry Champion power hammer, Figs. 1 and 2, is built in sizes from 50 to 500 pounds weight of ram, and strikes a maximum blow estimated at from 300 to 3,000 pounds, according to size. It is adaptable for a general line of forging, handling anything from the smallest up to a 7-inch piece. It is radically different from many styles of hammers and is a highly efficient and powerful machine, enabling the operator to work widely varying thicknesses of stock without change or adjustment.

In its construction the use of rubber cushions, leather straps, beams, saddles, coiled springs, or any form of spring and link connections has been entirely done away with, the elasticity and force of blow being imparted to machine through two steel arms, each with a tool steel roller at its lower extremities. These operate within the ram on a curved track, shown by the dotted line in Fig. 1, and lift and throw the ram. With increased speed on the hammer these arms acquire increased travel, going the full length of curved track, and thus imparting to the machine an elastic and powerful blow. This simple and positive action perfectly controls the ram and causes it to rebound instantly the blow is struck without reaction or jump, or any sudden or undue strain on any of the hammer parts. Ample provision has been made for both lengthening and shortening the stroke, but it is seldom necessary.

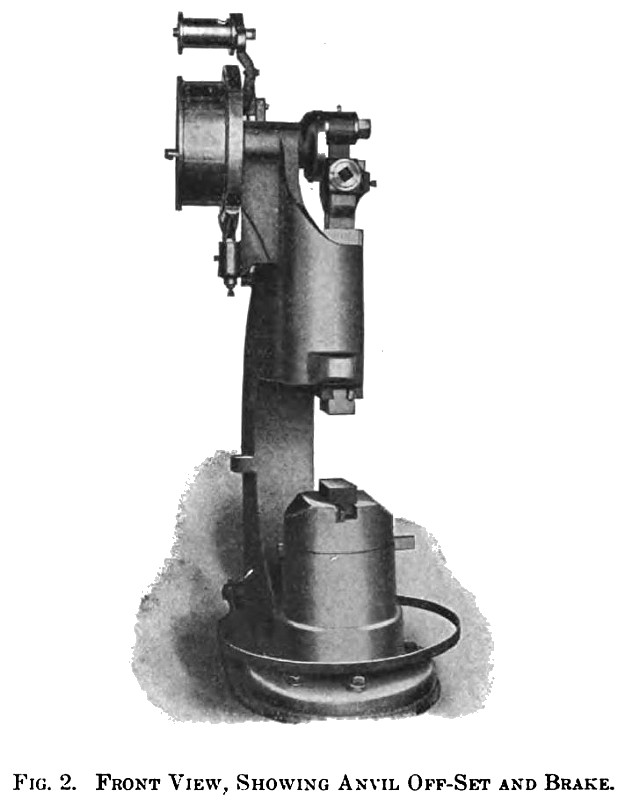

The machine is self-contained, rigid and occupies but small floor space. Its anvil is entirely separate from the frame, and sets off to one side, thus making possible the working of any length bars lengthwise as well as across the die. The ram is of steel carefully machined and fitted into heavy V-shaped guides with a flattened top. A wedge-shaped gib, shown in Fig. 1, is provided for taking up wear and lost motion. The ram is always well engaged in the guides and strikes a square, true blow at all times, there being absolutely no side play possible. All working parts are of such ample dimensions and material as to insure great durability. The shaft is of large diameter and long bearing, as is the crank pin, both of which run in phosphor bronze bushings. All working parts are of steel. A weight in the hammer pulley compensates for the weight of the ram and gives a balanced machine.

Particular attention is called to the cam brake as shown in Fig. 2. This is positive, instantly stopping the machine the moment pressure is released from foot treadle with the ram at its highest position and ready for the next piece of work.

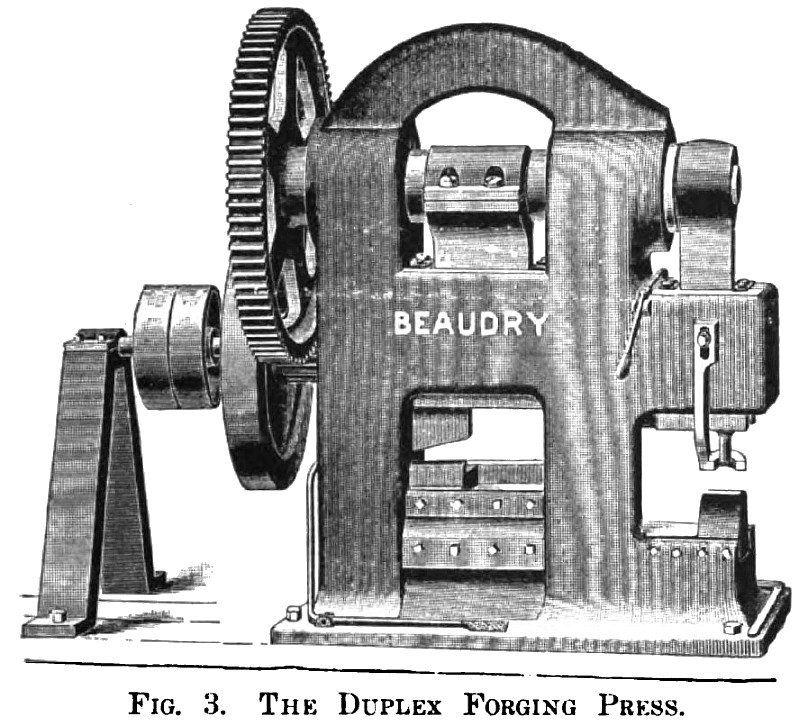

This hammer is built by Beaudry & Co., Inc., 141 Milk St., Boston, Mass. The duplex forging press shown in Fig. 3 is also manufactured by this company. It will be seen that there are two plungers on one crank shaft. These are so arranged that either one or both may be operated, as desired. The illustration shows the press arranged for doing shearing and punching, but provision is also made for inserting dies for forging, pressing or doing any other operation of this nature.

This press is built in a thoroughly substantial manner with each part of ample size and strength. The manufacturers claim that the solid rectangular housings especially adopt this machine to severe forging work, such as stone hammers, sledges, draw-bar heads, axe polls, eye bolts, as well as general forging and bending, cutting and punching structural shapes. This machine is regularly built with a stroke of 2 1/2 inches, will cut 2 1/4 round stock, flats 8 x 1, and will punch 1 1/2 x 3/4 inches. It can, however, be furnished with a stroke of 3 1/4 inches if desired |

|

1908 Beaudry & Co.-Power Hammer (Side View)

1908 Beaudry & Co.-Power Hammer (Side View)

1908 Beaudry & Co.-Power Hammer (Front View)

1908 Beaudry & Co.-Power Hammer (Front View)

1908 Beaudry & Co., Duplex Forging Press

1908 Beaudry & Co., Duplex Forging Press

|

|