|

Title: |

1927 Article-Cincinnati Bickford Tool Co., Super Service Drill Press |

|

Source: |

American Machinist, V67, 08 Sept 1927, pg. 409 |

|

Insert Date: |

7/16/2017 5:46:47 PM |

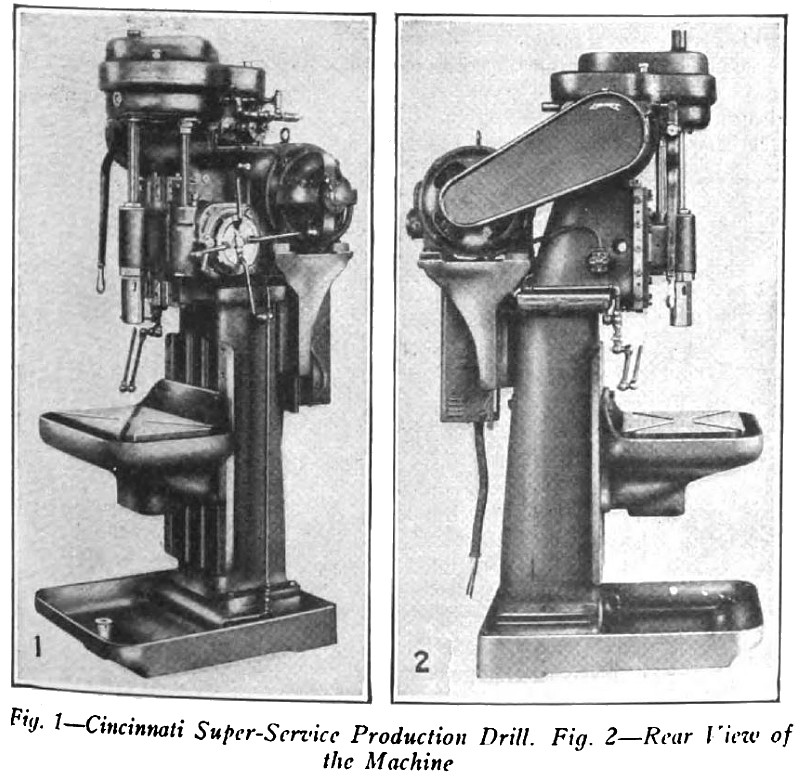

THE Cincinnati Bickford Tool Co., Oakley, Cincinnati, Ohio, has placed on the market the "Super-Service" production drill illustrated. The machine is intended to meet the specific requirements of the automotive and other mass-production industries, and is essentially a one-speed, one-feed, single-purpose machine. It is stripped of the features usually found on general purpose machines, but flexibility has been obtained in the design, so that by merely transposing gears 16 speeds and 16 feeds can l>e obtained.

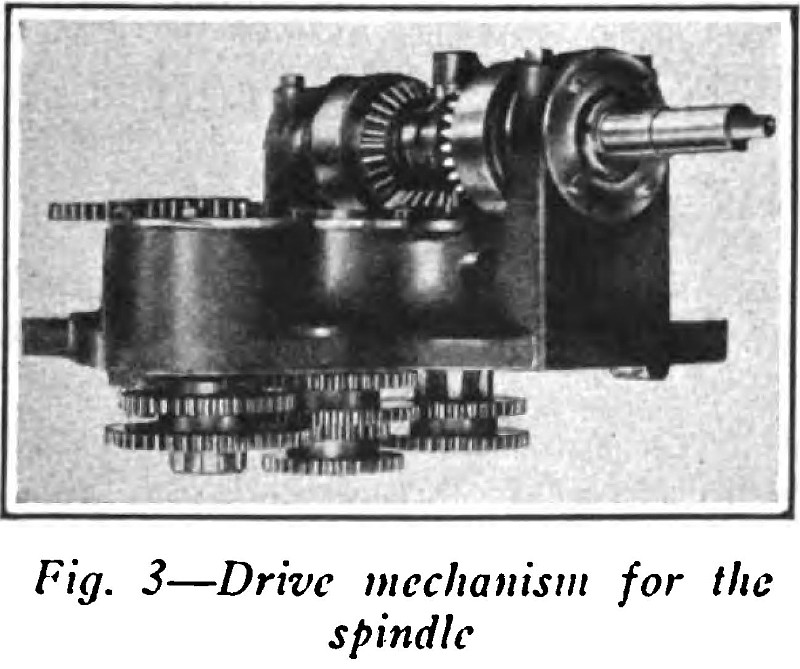

The forward and reverse driving clutches that comprise the tapping attachment are located on the main driving shaft. These clutches have high-power transmission capacity and run at constant speed. These clutches are of the internal expanding type, and are mounted on a continuous sleeve supported at each end by double row, New Departure ball bearings. The clutch mechanism runs in oil.

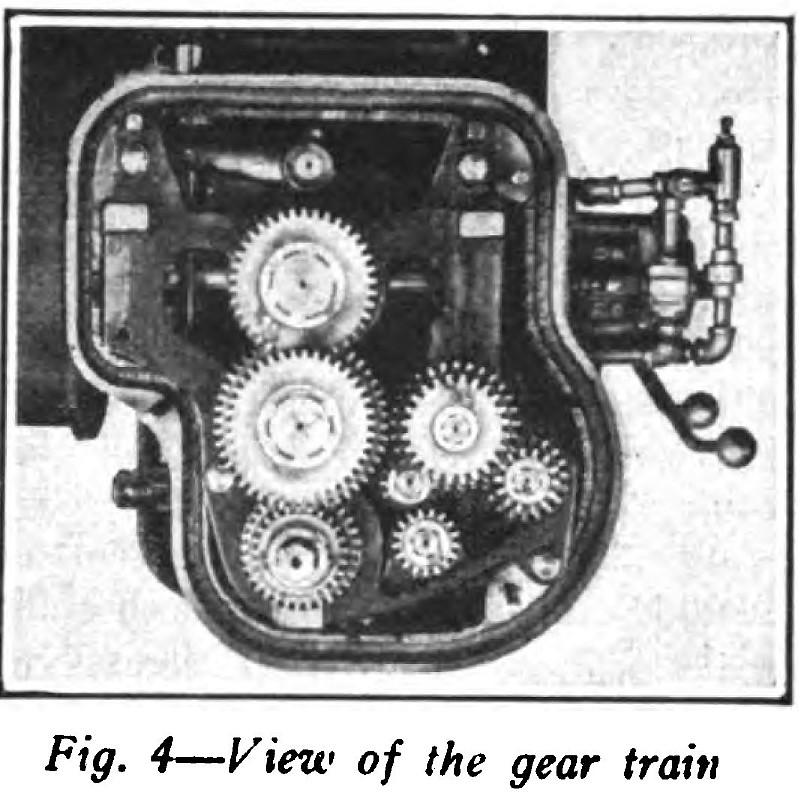

The speed gear train consists of four cluster gears of two gears each, which are interchangeable on three vertical shafts, so that sixteen gear combinations are possible. The speeds are graded, and range from 263 to 1,233 r.p.m. The gears are of heat-treated alloy steel, and each shaft is multiple splined and revolves in New Departure ball bearings.

The feed gear train is composed of four cluster gears of two gears each. These cluster gears are interchangeable on' four vertical shafts, giving sixteen closely graded feeds ranging from 0.0004 in. to 0.025 in. Both gears and shafts are of heat-treated alloy steel, and the feed gear train is lubricated by a splash system. The gears and shafts in the gear train are numbered for easy identification.

The spindle of the "Super-Service" drill runs in roller bearings. The upper bearing is Timken, and the lower is a Hoffman. The feed pressure is taken by a large ball thrust bearing. These bearings are packed in grease and require oiling attention only once in two or three months. The spindle is of special alloy steel, and is multiple splined. The spindle is attached to a slide, giving stiffness and rigidity at the spindle nose.

There is claimed to be no need for frequent vertical positioning of the work table on a machine of this type, and the usual raising and lowering mechanism has. therefore, been eliminated. The table is bolted to the face of the column, and holes spaced at close intervals permit of positioning the table according to the work to be done. This class of table is claimed to give greater rigidity. The column is of a heavy rectangular type, and consists of two sections. The construction permits of inserting raising blocks of various heights between the two sections when greater distances from the spindle nose to the work table are desired. For gang drill construction, it is merely necessary to mount the required number of upper sections on a common base.

The work table is surrounded by a deep, wide groove of large chip capacity, which is connected by large cored openings with a discharge on the underside of the table. Chips and cutting lubricant pass through the table and are discharged into the steel hopper beneath. The lubricant pump is driven from the main driving shaft and runs at a constant high speed.

The motor drive is through an enclosed silent chain running in oil. The motor recommended is 5 hp., 1,200 r.p.m., constant speed. |

|

1927 Cincinnati Bickford Tool Co., Super Service Drill Press

1927 Cincinnati Bickford Tool Co., Super Service Drill Press

1927 Cincinnati Bickford Tool Co., Super Service Drill Press (Spindle Drive)

1927 Cincinnati Bickford Tool Co., Super Service Drill Press (Spindle Drive)

1927 Cincinnati Bickford Tool Co., Super Service Drill Press (Gear Train)

1927 Cincinnati Bickford Tool Co., Super Service Drill Press (Gear Train)

|

|