|

Title: |

1945 Article-Kearney & Trecker Co.-Milwaukee Autometric Jig Borer |

|

Source: |

Machinery, V52, Oct 1945, pg. 201 |

|

Insert Date: |

7/13/2017 1:08:57 PM |

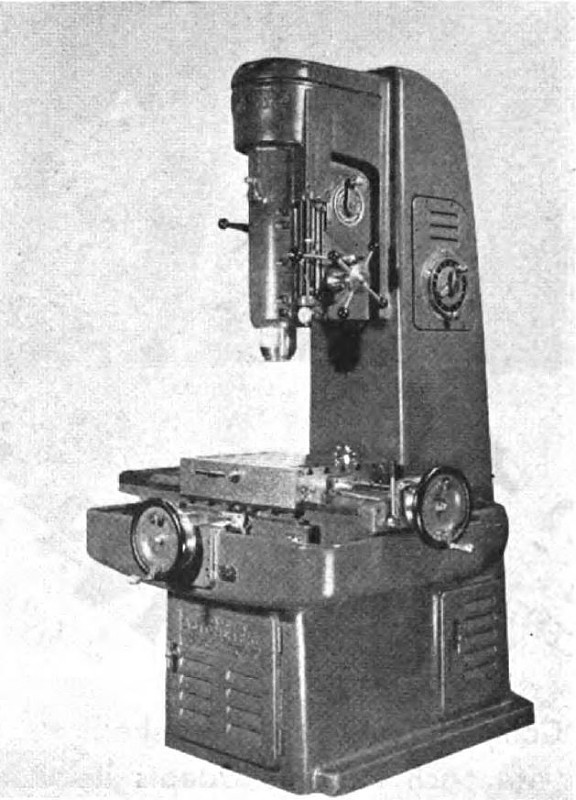

Milwaukee "Autometric" Boring Machine

The Kearney & Trecker Products Corporation, Milwaukee 14, Wis., has brought out a Model C Milwaukee "Autometric" boring machine, designed to handle a wide variety of precision boring ranging from the finest tool-room work to precision production jobs. The bed, column, and chip guard of this ma chine are cast in one unit, and the stationary boring spindle head is mounted on the machine column to provide a long bearing for the spindle quill. The head, spindle, and quill are specially constructed to permit sufficient quill travel to take care of the entire vertical range of the machine without increasing its over-all height, which is only 90 1/2 inches. The spindle has a No. 40 National Standard taper and a quick-change nut for convenience in changing tools. The spindle is driven directly by multiple V-belt from a 1-H.P. motor in the machine base, and the rapid traverse mechanism for the quill is driven by a 1/4-H.P. motor.

The precise transverse and longitudinal movements of the table are obtained by precision measuring screws equipped with large-diameter micrometer dials and verniers with 0.0001-inch graduations. Mechanical counters, which are set at zero during the initial set-up, show the exact table position in inches and tenths of an inch. The five pitch measuring screws give the table a movement of 0.2000 inch per revolution.

A lubricating system meters circulating oil to most of the running parts, including the spindle bearings. The outstanding features claimed for this machine include a high degree of accuracy, rigidity, and simplicity of operation. The lead of the measuring screws is accurate to 0.0001 inch in 1 inch and 0.0002 inch in 12 inches. All alignments affecting the accuracy of the work are held to within a non-accumulative error of 0.0002 inch in 12 inches.

The table has a working surface of 14 by 22 1/2 inches, a transverse travel of 12 inches, and a longitudinal travel of 18 inches. The maximum distance from the table top to the spindle nose is 17 inches, and the vertical quill travel is 11 inches. The spindle speeds are infinitely variable from 50 to 2500 R.P.M. Eight quill feeds are available, ranging from 0.0005 to 0.0148 inch per revolution of the machine spindle. |

|

1945 Kearney & Trecker Co.-Milwaukee Autometric Jig Borer

1945 Kearney & Trecker Co.-Milwaukee Autometric Jig Borer

|

|