|

Title: |

1851 Article-Brown & White, Taper Turning Lathe |

|

Source: |

Scientific American, 29 Nov, 1851, pg. 84 |

|

Insert Date: |

4/9/2017 7:44:44 PM |

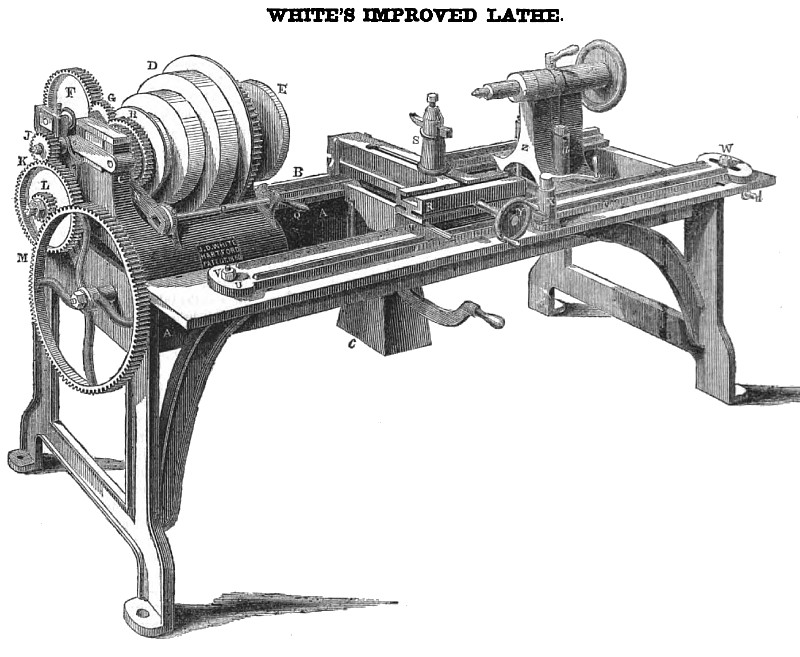

The accompanying engraving represents a Lathe of Mr. J. D. White, of Hartford, Conn., a patent for the principle of taper cutting being granted to him on the 2lst of May, 1850.

The engraving is a perspective view, and the lathe is one of the best construction, and the workmanship is of the best description. On page 267, of Volume 6, is an engraving of Mr. White’s double lathe for turning the axles of railway cars; an account of the nature and principle of this invention, is there set forth, and it requires but little to be said about that at this time. This is a view of the principle applied to the single lathe. That principle is a movable slide to guide the rest, and which can be set at various angles so as to turn tapes, and at the same time it is equally as good as any other lathe for every kind of work a lathe can perform. B is a slide on one side; the other is covered by the way. C is a fixed

The accompanying engraving represents a Lathe of Mr. J. D. White, of Hartford, Conn. a patent for the principle of taper cutting being granted to him on the 2lst of May, 1850.

The engraving is a perspective view, and the lathe is one of the best construction, and the workmanship is of the best description. On page 267, of Volume 6, is an engraving of Mr. White’s double lathe for turning the axles of railway cars; an account of the nature and principle of this invention, is there set forth, and it requires but little to be said about that at this time. This is a view of the principle applied to the single lathe. That principle is a movable slide to guide the rest, and which can be set at various angles so as to turn tapes, and at the same time it is equally as good as any other lathe for every kind of work a lathe can perform. B is a slide on one side; the other is covered by the way. C is a fixed standard of the gearing; D is the train of pulleys; E is the live centre; E G F J K L M are the train of gear wheels and pinions for the different kinds of turning, &c., to give the requisite velocity to the screw shaft, and M is the gear wheel of the same. This shaft passes through the screw eye on the slide rest, (but which cannot be seen) in the usual way. R is the slide rest; S is the tool stock with the cutter inserted in it; Y is the screw for setting the tool at the proper distance to act on the article to be turned; Z is the movable poppet centre head; a is a screw bolt (there is a like one on the other side) to fasten it down on the table; U is the movable way to be set in and out at various degrees, to cut tapers. It guides the slide rest R. V is its pivot axis. W is a screw to fasten it at the movable end. It works in the slot, the use of which will at once be perceived. This

movable guide way is reversed quickly by a pinion on Y, working into a rack, b, on the edge of the guide way. c is the draught weight. Q is a handle to operate the rod, P, and an eccentric lever, N, to throw the gears in and out, with pinions on the back shaft, for changing the velocities as mentioned; d is a screw for setting the movable guide way in and out to the proper distance. This lathe is well adapted to chucking, and its utility for parallel and taper turning is self-evident. By using a card of reference, this lathe can be set in an instant to cut the same taper a year hence, which may be cut today.

This lathe is for sale at Leonard’s machine depot, No. 106 Pearl street, this city, where it may seen, an examination of it will be of interest to all machinists. Mr. White is now manufacturing these lathes. He produces none but the very best work.

US Patent: 7,390

http://datamp.org/patents/displayPatent.php?number=7390&typeCode=0 |

|

1851 Brown & White, Taper Turning Lathe

1851 Brown & White, Taper Turning Lathe

|

|