|

Title: |

1869 Article-Delamater Iron Works, Rider's Vertical Steam Engine |

|

Source: |

Manufacturer and Builder, V1, Nov 1869 pg 353 |

|

Insert Date: |

3/5/2017 10:00:46 PM |

The Rider Engine

The importance of using steam expansively is so generally conceded that there is no longer any room for discussion on this point. Now and then we find men who stand ready to deny, the Value of a good cut-off; but so too men have been found to deny the first principles of geometry and the plainest axioms of physics. And if it has happened that men with this obliquity of mechanical vision have sometimes occupied high positions in the service of the state—chief engineer of the navy, for example— still this is not to be wondered at, nor does it prove anything. No man can possibly be so ignorant or stupid that ho is unfit for a government position. Wo have had a postmaster-general so ignorant of natural history as to deny that a nut is a seed; a commissioner of agriculture who did not know that hydraulic presses do not depend for their power upon screws; judges who have denied that birds are animals; and men in every position who firmly believe that whales arc fish. But on the whole, we prefer the general common sense and experience of mankind to the special crotchets of the few, and the weight of opinion is most decidedly in favor of the employment of a good cut-off. The only difference of opinion is in relation to the excellence of the mechanical arrangements employed to secure the desired result. Most of the cut-off valves employed are too complicated, and hence they are adapted only to the largest class of engines. In the engravings, which illustrate this article, however, the reader will find a representation of a form of cut-off valve which is remarkable for its simplicity and efficiency. The following description will, with the aid of the engravings, render its construction and operation perfectly clear:

In short-stroke engines, where the ordinary three-port valve is generally in use, the main slide valve is, in its action, and in the form of its face side, similar to that of the well-known slide-valve, with the exception that its ends are lengthened to admit of steam-ports or openings being formed outside of the valve proper. These openings or ports are. on the fate side of the valve, rectilinear and rectangular to the motion of the valve, that is, they run parallel with the ports in the cylinder or disposed square across the valve-seat. On the back of this main valve, where the cut-off valve is fitted, these steam ports are oblique, and at opposite angle's to each other, the use of which will be presently explained. The cut-off valve is a sector of a cylinder, with its ends cut off obliquely in opposite directions; so that the extremities or acting ends of the cut-off valve respectively conform to the lines of a right and left-hand screw of high pitch, corresponding to the obliquity or angle of the steam-ports in the back of the main slide-valve. This cut-off valve just described is fitted into a semi-cylindrical recess in the back of the main slide-valve, and between the spiral openings. It is operated lengthwise by a separate eccentric, to which it is attached in the usual manner, excepting that it has a swivel-joint to permit its partial rotation. A portion of the valve-stem is made square, or sometimes arranged with a " feather," and at this place, on the valve-stem, is fitted a sector, engaging a rack on the lower portion of the governor-spindle, Bo that as the governor rises or falls, the cut-off valve will partly rotate. Thus, the cut-off valve is moved lengthwise by the eccentric, and, at the same time, has imparted to it, by the governor, an adjusting motion on its axis. As a consequence of the radial motion imparted by the governor, and the spiral form of the steam ports and acting ends of the cut-off valve, the distance be. tween the openings and the ends of the valve is varied within very wide limits, the effect being to cut off the steam at any point of the stroke. The arrangement may be compared to a right and left-hand screw, formed by the shape of the valve ends and the openings. This device is extremely sensitive to the action of the governor, as the rectilinear motion by the eccentric causes the radial or axial movement of the cutoff valve to be effected by the least possible amount of force. This compound motion also highly favors the perfection and durability of the surface. In engines of a larger size, where it is desirable to have short steam-passages, the main and cutoff valves are divided through the centre, and each end carried outward to act on the steam-ports of the cylinder at its ends, as is usual with the ordinary slide-valves as severally constructed.

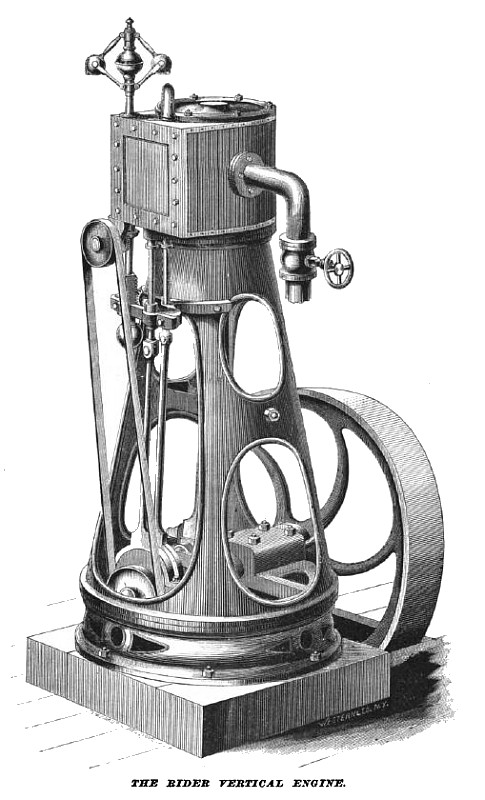

The vertical engine, of which our engraving will give a good idea, is remarkably compact, neat, and efficient. At the late fair of the American Institute one of these engines, rated at about eight horse-power, was kept in constant operation, and from the small space occupied by it, and the economy of fuel which it exhibited, it gave very general satisfaction. Alongside this upright engine was placed a which it absorbed in the boiler on being changed from liquid water into gaseous steam; this latent heat is given off, set free, when the steam arrives in the steam coil, and there condenses from gaseous steam into liquid water. |

|

1869 Delamater Iron Works, Rider's Vertical Steam Engine

1869 Delamater Iron Works, Rider's Vertical Steam Engine

|

|