|

Title: |

1872 Article-Thorne & De Haven, Portable Drilling Machine |

|

Source: |

Modern Machinery, V4, Jan 1872, pg. 1 |

|

Insert Date: |

2/28/2017 1:05:30 PM |

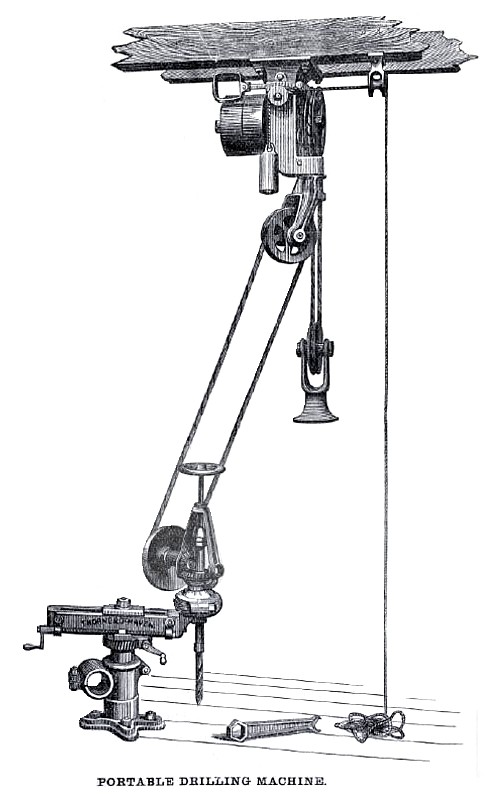

New Portable Radial Drilling-Machine

EVERY mechanic who has ever had occasion to use the ordinary ratchet-drill, will at once appreciate the many 'advantages of the ingenious invention depicted in our engraving. The great practical utility of an instrument which, while combining all the advantages of the heavy upright drill, is easily transported to any part of the shop and readily adapted to any variety of work, cannot but be apparent to everyone.

The operation of the machine is as follows: The counter-hanger is bolted to the ceiling or other convenient place, and receives power from the "line-shaft” by a flat belt on the fast and loose pulleys. The frame carrying the “idlers” rotates on a hollow stud, through which the round belt passes to the grooved driving pulley. The rotation of this frame permits the belt to be led to the drilling-machine in any direction radially from the hanger, while the rise and fall of the weighted "idler" permits it to be led to any point within the scope of this rise and fall, say 10 to 15 feet or more. By inserting sections of belt by means of the hook-couplings, any distance can be reached.

The post of the drilling-machine is intended to be bolted or clamped to the piece to be drilled. Its height can be adjusted to suit the different length of drills and chucks used in the spindle. The rest of the ma chine is then fastened to the post, the position of the drill being adjusted by means of the radial slotted arm or jib. When it is required to drill parallel with the base, the jib is held in\the clamp on the side of the post. There is a shoulder turned on the bottom of the ball on the gear-frame, and a half collar fitted to it and bolted to the jib. This keeps the spindle square with the base, avoiding the necessity of setting it when the cone is being adjusted in line with the belt. “when this half collar is removed, the spindle can be set to an angle (under 30 degrees) in any direction.

These machines can be placed with greater facility than a ratchet-brace, and will drill at any angle, in any position, at any distance, and in any direction from the power. They are adapted to drilling bolt-holes in cylinder flanges, steam-chests, beds, etc., of engine-work, and in all pieces of machinery which are inconvenient to move, or which cannot be readily adjusted under stationary drilling-machines. They are specially needed in locomotive, marine, and all erecting ~ shops, and can be used in yards adjoining shops, on columns, architectural work, water mains, iron ships, iron bridges, etc. They are useful in boiler-shops for drilling the plates when in position. For railroad repair-shops they are a tool long needed, and soon pay for themselves in the saving of time and excellence of work. For small machine-shops, they supply the place of a radial drill at a fraction of the cost. For foundries, they supplant the tedious, inaccurate, and expensive hand-drilling with the ratchet.

The time required to set and adjust them is much less than required to rig up a ratchet-brace or “old man”. The speed of drilling is equal to that of a stationary drill-press. The workmanship on these machines is equal to that of the best machine tools made. The spindles and shafts are of steel, the bearings of brass, and the gears of malleable iron. The No. 1 machine will drill up to 1¼ inches diameter. The spindle is of 1¼ inches, steel, and its socket is the same as the No. 2 Morse twist drill-socket. It has 6 inches feed. The post has 5-inches vertical adjustment. The cone has three steps, suited for ½-inch round belt. The jib has 12-inches radial adjustment. Price, complete with wrenches and driving apparatus, $200. Weight of portable machine, 100 pounds. Weight, complete, boxed, about 320 pounds.

The No. 2 machine will drill up to 2¼ inches diameter, “in the solid," and bore up to 3¼ inches with boring-bar and cutter. The spindle is of 1½ inches steel, and its socket is the same as a No. 3 Morse twist drill socket. It has 6 inches feed. The post has 6-inches vertical adjustment. The cone has 4 steps, suited to ½-inch round belt. The jib has 15-inches radial adjustment. Price, complete with wrenches and driving apparatus. $250. Weight of portable machine, 180 pounds. Weight, complete, boxed, 450 pounds. |

|

1872 Thorne & De Haven, Portable Drilling Machine

1872 Thorne & De Haven, Portable Drilling Machine

|

|