|

Title: |

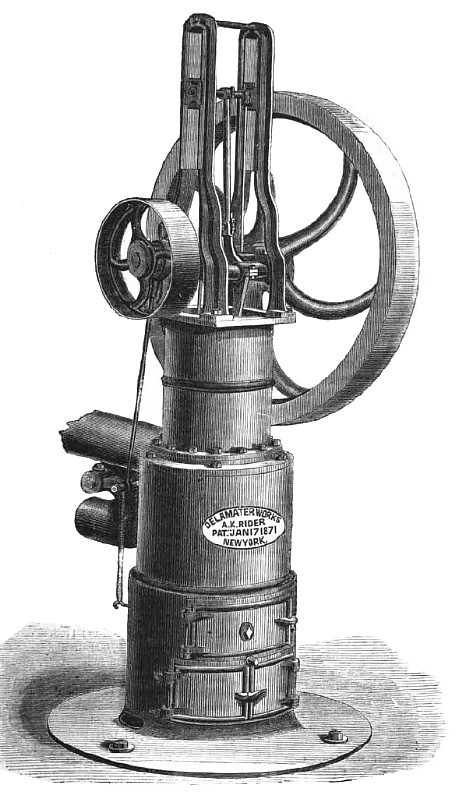

1871 Article-DeLamater Iron Works, Rider's Hot Air Engine |

|

Source: |

Manufacturer & Builder, V3, Sept 1871, pg. 209 |

|

Insert Date: |

2/25/2017 12:27:54 PM |

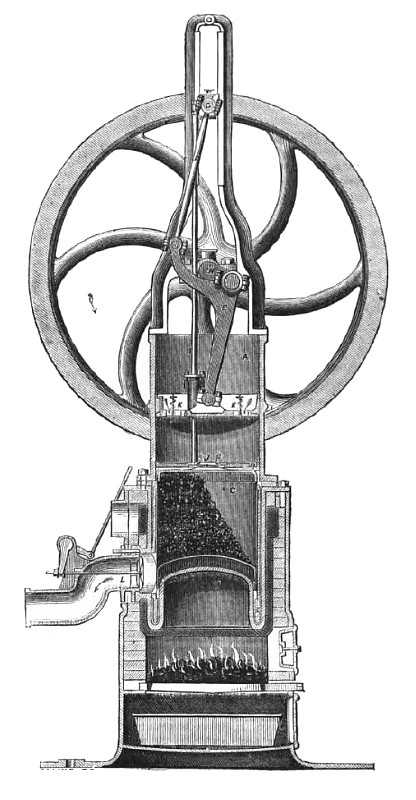

The Rider Caloric-Engine

Explosions of steam-boilers with attending disastrous consequences have of late become so frequent that the public feel the necessity and importance of a motor in which their use shall be obviated. In many instances, as where power is required for light manufacturing purposes, or where a saving in fuel or hands is desirable, the use of the steam-engine with its boiler may for various reasons become objectionable, and the substitution of some other machine, which can be easily managed and is of sufficient power, becomes preferable.

It is in such cases that the caloric-engine has been found useful, and in consequence it may. in a measure supersede the steam-engine; and as it fulfills the conditions of economy, facility of management, and freedom from danger, its use has resulted successfully in a number of instances.

The Rider caloric-engine, the subject of our illustration, is claimed to be one of the best of the many of its class. Its construction is based on the application of correct principles, established by careful trials with all forms of hot-air engines, and is so simple as to require but a brief description.

The cold air is drawn in through valves in the upper or main piston, by the rapid descent of the shifter, which movement at the same time expels the heated and power-exhausted air below it through the exhaust valve L. When the main piston has reached half-way down its stroke, the shifter is at the bottom of the cylinder, and the space between the pistons is full of fresh, cold air. At this point the exhaust-valve closes, and as the main piston progresses in its stroke downward, the air is compressed into a much smaller space, and consequently has a higher pressure; the shifter now returning on its up-stroke, rapidly approaches the main piston, causing the cold and compressed air to pass through the valve J into the heater, as shown by the arrows. Here it is dilated by the heat, and, by increased volume and pressure, drives both pistons (which have now come into close contact) upward to the termination of the up-stroke, at which point the exhaust-valve opens and the operation is repeated.

It will be seen that the side-motion of the connecting-rod imparts a peculiarly regulated vertical motion to the cross-head G, through the links F, and thence to the shifter through the rods t, t; this simple device accurately producing the graduated motion of the shifter, on which the efficiency of the engine so much depends.

It will also be seen that the cold air is drawn through the main piston at each stroke ; this keeps the main piston and packing cool, and adds greatly to the durability of the packing and cylinder. The great advantage of dispensing with a separate pump is also apparent in the economy of material and friction.

It has many other advantages claimed for it, some of great importance. In common with its class, it uses no water, and consequently cannot explode, freeze, nor rust; its cost is less than that of the steam-engine, while it may be used in many cases where the same is inadmissible or inapplicable. As before stated, the construction is simple, and it is economical of fuel and repairs, while it requires but little skill and attention in management. The Delamater Iron-Works, in West Thirteenth street, in this city, now make two styles of this engine, one for power purposes for printers, founders, machinists, etc., and the other for pumping for residences, hotels, breweries, railroad water-stations, etc. The latter style is made in two sizes, 9 and 13 inches diameter of working piston. The 9-inch engine will raise 850 to 900 gallons of water per hour to the height of 50 feet, and the 18-inch will raise to the same height 2,700 gallons per hour, or a proportional quantity any required distance. The power engines are manufactured of 1, 2, and 4 horse-power, with diameters of cylinder respectively of 13,18, and 25 inches, and work at 80 revolutions per minute.

No pains have seen spared. The materials and the workmanship of this engine are of the best quality, and the well-known reputation and extensive experience of its manufacturers will insure its being fully up to the highest standard.

US Patent: 111,087

http://datamp.org/patents/displayPatent.php?number=111087&typeCode=0 |

|

1871 DeLamater Iron Works-Rider's Hot Air Engine

1871 DeLamater Iron Works-Rider's Hot Air Engine

1871 DeLamater Iron Works-Rider's Hot Air Engine (Sectional View)

1871 DeLamater Iron Works-Rider's Hot Air Engine (Sectional View)

|

|