|

Title: |

1893 Article-F. H. Crafts, Engine Lathe |

|

Source: |

Iron Trade Review, V26 22 Jun 1893, pg. 13 |

|

Insert Date: |

2/23/2017 12:53:04 PM |

New Driving Device for Engine Lathe

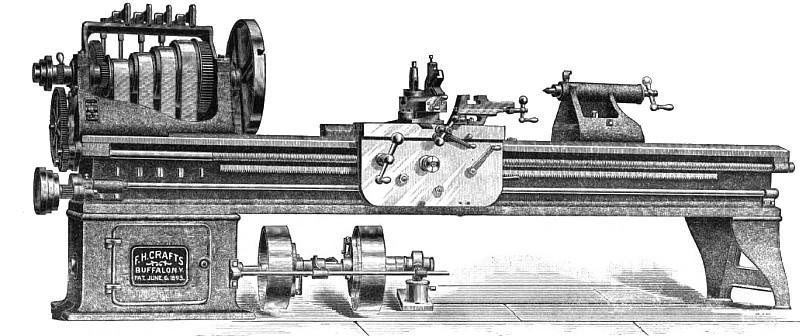

F. H. Crafts, senior member of the Buffalo Wood-working Machine Co., Buffalo, N. Y., has invented a driving device for engine lathes and other machines employing cone pulleys. The accompanying cuts give front and rear views of a 22” swing engine lathe embracing the new device. The lathe was built in Cincinnati, by leading tool-builders, and at the experimental trial a number of manufacturers were present, and expressed their satisfaction with the results. The lathe has been subjected to the severest tests, with gratifying results, and there seems to be no doubt of its future.

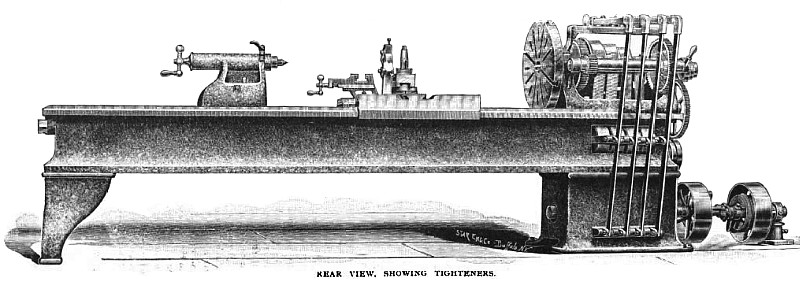

The usual methods employed in driving engine lathes are completely reversed by the substitution of this device, as the countershaft is placed directly underneath the spindle. Each one is provided with a light double endless belt, entirely free from rivets. In other words, a four-step cone would have four belts. Each belt has its own tightener. These tighteners are controlled by a series of levers having notches planed in them at intervals of one-half inch. This insures perfect control of the belts, and any tension can be secured suitable to the character of the work done. As the belts are now pulling down on the spindle, they counteract the influence of the up thrust of the tool, and the strain is taken off the top of the head stock. By the employment of tighteners more lap of the belts are secured, and less tension of the same is required to accomplish the work. When the lathe is not in operation, the belts being in a slack condition, the same will take up and retain their elasticity, thus prolonging their life indefinitely. The countershaft can be reversed, and the same can be belted from below or above as occasion requires. Independent of the means employed to drive the above lathe there are many other good features embraced in its construction, which will commend themselves to all practical men.

The spindle is of crucible steel, is hollow and runs in carbonized phosphor-bronze bearings. The front bearing being 3 1/4” diam., 5 5/8” long, back bearing 2 3/8” diam., 4 3/8” long, and with the means employed to insure perfect lubrication, there should be no perceptible wear on the boxes for years. The feed—belt is made endless, and can be instantly tightened if it should become slack. This is accomplished by placing the cone on an independent stud, the plate carrying the stud being arranged to swing on the feed-shaft. The cross feed is simply and quickly adjusted, and when in use the table is firmly clamped to the ways by the use of lever shown in cut. All parts of this machine are made unusually heavy and independent of the driving device. The lathe swings 22” over ways and 14’ ’ over carriage. Improved noiseless friction clutches are provided 14” diam., 4” face, and the same should make 140 turns per minute. Preliminary steps have been taken to build all sizes of lathes and other machines employing cone pulleys, in which will be embraced drills, shapers, milling machines. pulley lathes, chucking mills, cutting-off machines, boring and turning mills and other. All driving belts on the cones and the feed belt will be furnished with the lathe unless otherwise ordered. The weight of the 22” lathe, 12’ bed, is 4,100 pounds. The inventor, F. H. Crafts, or the Buffalo Wood-working Machine Co., Buffalo, N. Y., will gladly answer inquiries. |

|

1893 F. H. Crafts, Engine Lathe

1893 F. H. Crafts, Engine Lathe

1893 F. H. Crafts, Engine Lathe (Rear View)

1893 F. H. Crafts, Engine Lathe (Rear View)

|

|