|

Title: |

1921 Article-Joshua Buckton & Co., More Shop Views |

|

Source: |

The Engineer, 12 Aug 1921, pg.167 |

|

Insert Date: |

2/8/2017 7:33:34 PM |

|

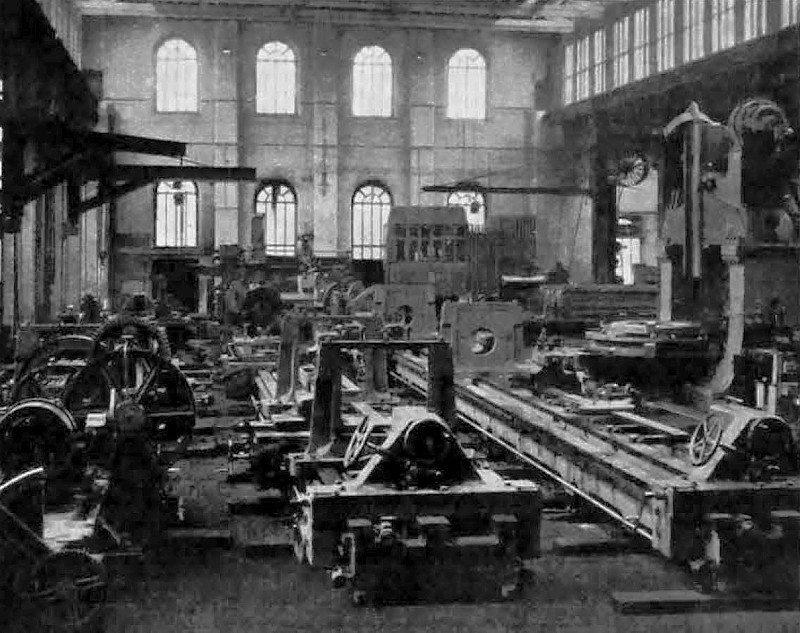

Adjoining the turning shop is the light erecting shop—see Fig. 8—which at the time of our visit was chiefly occupied by testing machines and machine tools under construction, the latter ranging up to 20 tons in weight. The shop is served by 7½ ton overhead electric cranes. Next to it again is the erecting shop for the heavier tools—see Fig. 9. It is served by a 25-ton overhead electric crane and has direct communication with the fitting shop, where detail parts are prepared for the erectors. In the tool-room adjoining the cutting tools, reamers, drills, &c., are made and stored, being kept, in order, checked and issued to the workmen as required. The same department takes charge of the limit gauging system, which is in universal throughout the establishment, in spite of the fact that repetition work as usually understood is conspicuous by its absence. Messrs. Buckton's work is almost exclusively individual and covers a wide variety of machines built to comply with special requirements. Nevertheless, the proprietors are firm believers in the advantages of limit gauging. The gauges are issued from the tool-room only as required for the jobs at hand. They are returned to the same department on the completion of each job, carefully checked and, where necessary, adjusted before re-issue. Very accurate measuring apparatus is made use of for this purpose, and its use is confined to a very limited number of persons, thus, as far as possible, eliminating variations due to the human element. The working drawings indicate whether the parts of machines are to be made running fit, a keying-on fit, &c. Suitable “go " and “not go " gauges are than issued to the borers and turners, who do not need to be further concerned with the exact dimensions of these parts, saving, of course, to make the work be the gauges issued. The next shop contains all the reciprocating machine tools, such as planing machines, varying from those capable of dealing with objects from 3ft. wide by 3 ft. high up to 12 ft. wide and 10 ft. high, slotting, shaping and boring machines. This shop is served by a 20 ton overhead travelling crane. All the machines in this section, as well as all the larger lathes and drilling machines, are of Buckton’s own make. The individual motor drive is adopted for the planing machines, the larger machines being provided with reversing motors and the smaller ones with constant-speed motors and change-speed gear-boxes. A certain amount of erecting work is also performed in this department, which serves as an overflow the main erecting shop. Over the fitting shop is a large store-room where finished end semi-finished parts of machines are stored under the charge of a foreman and re-issued when required for further processes. This obviates the confusion, loss and deterioration, which ensues in some shops in which finished work is allowed to lie about the shop. The northernmost portion of the works. comprises a block of buildings, the upper stories of which are used as pattern stores and the ground is fitted up as a comfortable and commodious canteen. The latter is divided into two sections with the kitchen in between, the larger portion being used by the workmen and the smaller side for the office staff and foremen. The canteen is managed entirely by a committee of the employees, which fixes the prices of consumables, makes the purchases, and has general control of the arrangements. It says much for the management that practically all the firm's workers who do not live near enough to the works to go home for their meals, and many who do patronize the canteen. |

|

1921 Joshua Buckton & Co., New Turning Shop, Fig. 7

1921 Joshua Buckton & Co., New Turning Shop, Fig. 7

1921 Joshua Buckton & Co., Light Erecting Shop, Fig. 8

1921 Joshua Buckton & Co., Light Erecting Shop, Fig. 8

1921 Joshua Buckton & Co., Erecting Shop for Heavy Tools, Fig. 9

1921 Joshua Buckton & Co., Erecting Shop for Heavy Tools, Fig. 9

|

|