|

Title: |

1921 Article-Joshua Buckton & Co., Shop Views |

|

Source: |

The Engineer, 12 Aug 1921, pg.166 |

|

Insert Date: |

1/28/2017 12:48:14 PM |

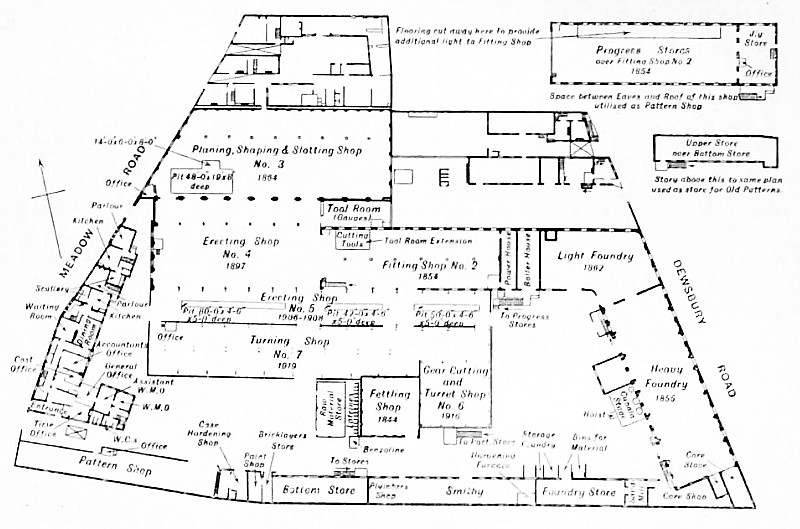

The plan, Fig. 5, gives a very good idea of the growth of the establishment from the early days to the present, the dates of erection of the various buildings being given. An inspection of the buildings provides an object lesson in the evolution of factory construction from the days when wood and cast iron were chie?y used, to the present days of rolled steel and concrete. The most recent extension—it has been carried out since the termination of the war—consists of a new turning shop, to which we shall refer again later. The works, covering an area of 15,200 square yards, are now organized on the principle of grouping together all machines of a similar type. With that object the reciprocating tools, such as planing, shaping and slotting machines of all sizes, are concentrated in one department, the lathes in another, while the drilling and boring machines are distributed about the fitting and erecting shops in order to reduce the movements of heavy parts from one place to another.

The offices front on Meadow Road. On the ground floor are the timekeeping department, the costing and purchasing departments, and the works managers’ offices, all communicating directly with one another. On the first floor the accounts department, correspondence office, directors' office, and drawing-office are found in the order mentioned, with direct communication throughout so an to save walking time on the part of the staff. The top ?oor has room for the storage of drawings and documents not in regular use. There is also on this floor a well-equipped photographic studio containing an electric printing apparatus for drawings and everything essential for the production of photographs of the machines. In this connection, it may be mentioned that Mr. Joshua Buckton claimed to be the pioneer of photographic. illustration of machine tools.

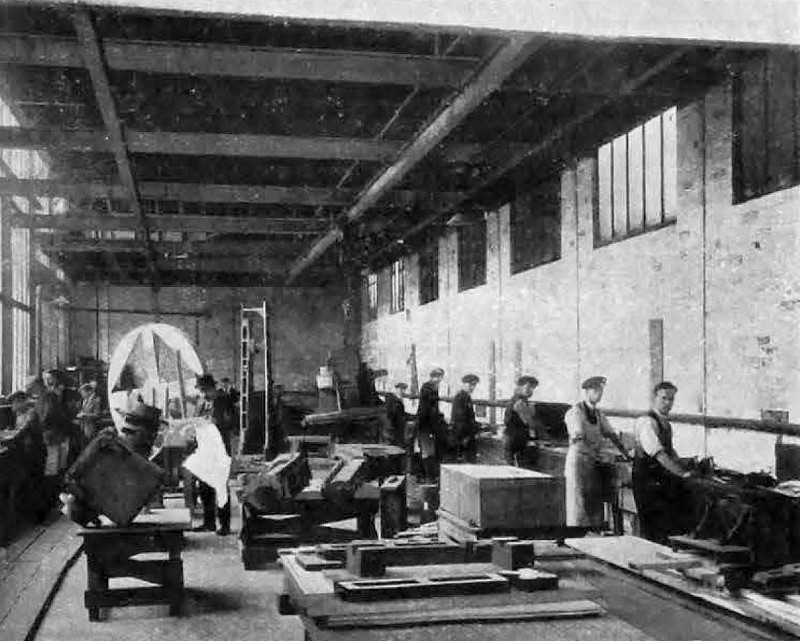

Passing from the offices into the works, we come first to the new pattern shop, a lofty and commodious building measuring 150 ft., by 24 ft., with the front entirely of glass to give ample light.—see Fig. 6. The woodworking machines for this department are in a building at the end of the pattern shop and, in common with all the plant in the works, are driven electrically. The next. building beyond the pattern shop in the original four-story warehouse existing in 1838, which now fulfills a useful purpose as a general store for materials and small goods to be used in the works. In the same line of buildings are the case-hardening and smith’s shops, the latter containing steam and pneumatic hammers. At the far end of the yard is the foundry, which consists of two buildings recently thrown into one, in order to give more flour space for the production of small castings while allowing the space in the main building for heavy work. The foundry in equipped with two overhead cranes, a large core stove, three cupolas, and the usual sand grinding and mixing machinery. It is, so we are informed, capable of producing individual castings up to 25 tons in weight. The yard space in front of the foundry is utilized for the storage of various classes of pig iron and coke. A square building in the middle of the yard, which was once the firm's foundry, is now adapted to fettling purposes. Following the boundary of the site there is a range of buildings recently acquired by Messrs. Buckton for the purpose of extensions, but used meantime as pattern stores.

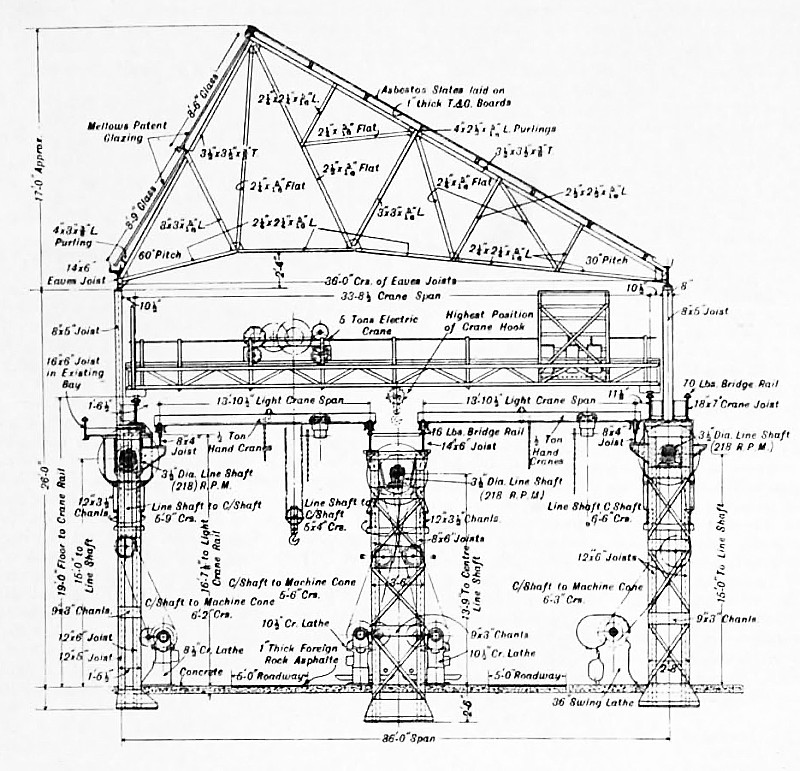

Immediately to the west of the foundry is the boiler-house, containing a Lancashire boiler, the purpose of which is now solely to supply steam to the hammers and heating apparatus. Next to the boiler-house is the engine-room, containing a horizontal steam engine kept as a stand-by in case of failure of the electric power supply derived from the Corporation mains. The same house contains the hydraulic pumps and a motor transformer. The current supplied by the Corporation being of the alternating variety, it is necessary to transform a portion to direct current for use by the electric cranes and machines driven by variable-speed motors. Adjoining these departments are the main shops, the most southerly being the new turning shop—Fig. 4—measuring 258 ft. by 36 ft., with an annex containing automatic and capstan lathes. As will be seen from the drawing, Fig. 4, and the half-tone engraving, Fig. 7, the main turning shop has three line shafts extending from end to end. each being driven midway in its length by an alternating current motor of 50 horse-power. This building is a steel structure with brick footings, the roof being of the right-angled saw-tooth type, close boarded and covered with asbestos tiling on the south and glazed on the north aide. The two outer line shafts are carried on the main structure of the building and the central shaft is supported on a gantry very strongly and rigidly constructed of steel joists and channels. Provision is thus made for driving four lines of lathes, with ample working space for the men and for the handling of materials. Running the whole length of the shop and spanning right across it is a 5-ton electric overhead crane, and spanning each half of the shop from the gantry to the side girders are hand-operated cranes capable of lifting 30 cwt. These latter cranes am at the individual disposal of the turners. In this shop we noticed. lathes from 6½ in. to 18 in. centres, many of which are quite new. Them are also cylindrical and surface grinding machines, the practice of finishing spindles and shafts by grinding having been definitely adopted by the firm. There is a number of gear-cutting machines of various makes, the latest being of the Sunderland type.

Here it should be mentioned that Messrs. Buckton have for some years adopted a special stub tooth form of their own. It is of the short involute variety, and consequently the cutters used are made specially to produce it. In the early days of the firm and before the introduction of machine-cut gearing, Messrs. Buckton mad a special feature of cast gearing which was noted for its accuracy. As far back as “ the ‘forties " they constructed and sold wheel-cutting machines designed for the accurate production of patterns for cast teeth. It will be seen, therefore, that accurate and well-designed gearing is no new thing in these works, and the present practice of machine matting gear wheels has been evolved through many years of study of the subject. |

|

1921 Joshua Buckton & Co., Cross Section of New Turning Shop, Fig. 4

1921 Joshua Buckton & Co., Cross Section of New Turning Shop, Fig. 4

1921 Joshua Buckton & Co., Plan of Well House Foundry, Fig. 5

1921 Joshua Buckton & Co., Plan of Well House Foundry, Fig. 5

1921 Joshua Buckton & Co., New Pattern Shop, Fig. 6

1921 Joshua Buckton & Co., New Pattern Shop, Fig. 6

|

|