|

Title: |

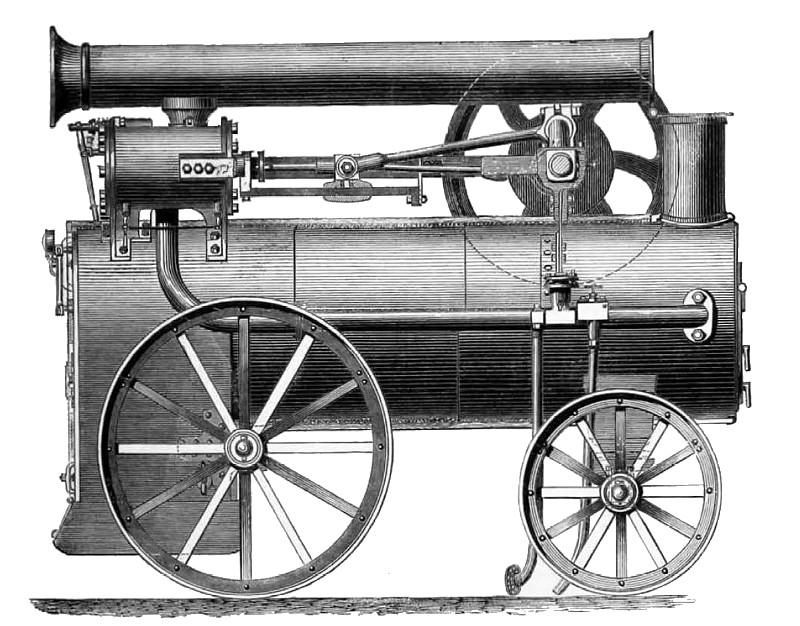

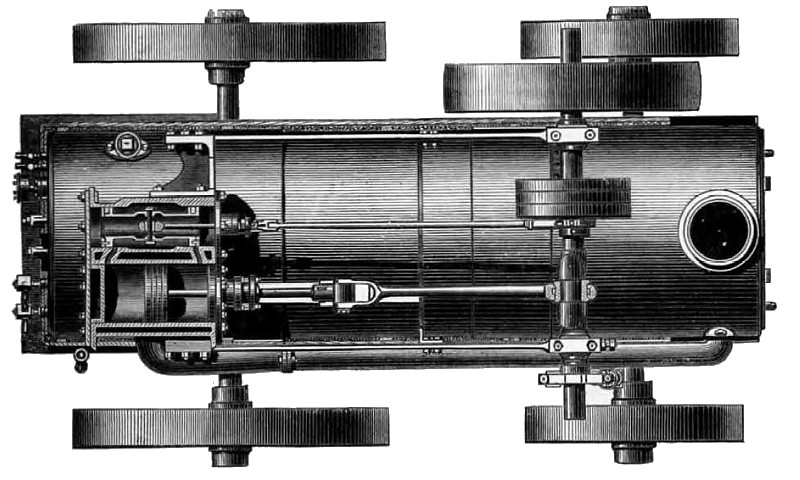

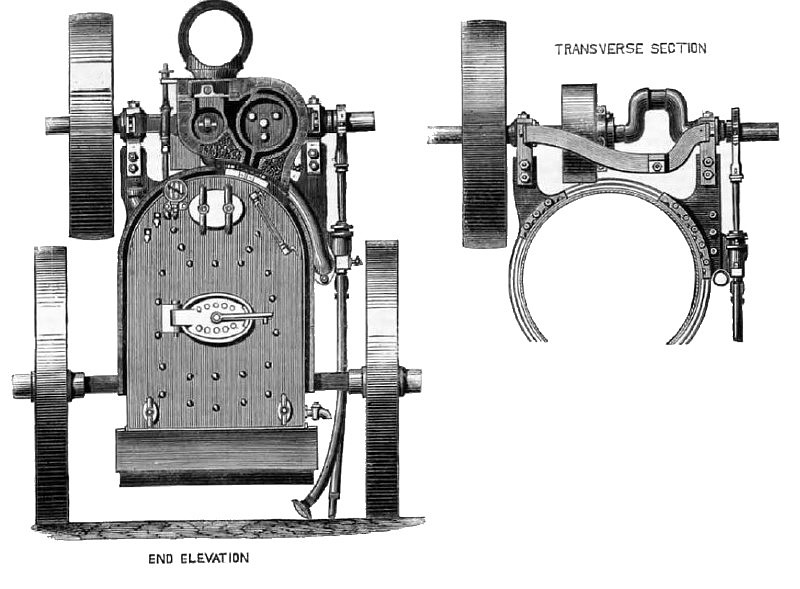

1872 Article-E. R. & F. Turner Portable Steam Engine |

|

Source: |

The Engineer, V 34, 19 Jul 1872, pg. 40 |

|

Insert Date: |

1/7/2017 9:02:10 PM |

This engine embodies the patent of the makers for their piston slide valve, and of Messrs. Hartnell and Guthrie for the governor and side frames. It is especially adapted for high piston speeds and pressure, working during the recent trials at the Cardiff show at 80 lb. pressure, and 360 ft. of piston speed per minute. Under the usual arrangements of portable engines great strain is thrown on the boiler, frequently causing leakage of the seams, and loosening the bolts for securing the crank shaft brackets. In this engine, a rigid connection is formed between the cylinder and crank shaft bearings by means of light wrought iron side frames of rectangular section. These are bolted to the cylinder at one end, and at the other embrace the adjustable bearings of the crank shaft, where they are supported by two transverse plates only, secured to the boiler. Ono of these plates also carries the feed pump. A wrought iron stretcher plate between the frames carries the guide her. The safety valve and starting valve are on the cylinder. The engine is practically self-contained, and nearly all the working stains are borne by the frames independent of the boiler. The engine has no throttle valve, the speed is regulated by varying the position of the slide valve eccentric. The governor is placed in a drum on the crank shaft adjacent to the eccentric, containing two cast-iron weights placed on opposite sides of the shaft connected by a tie rod, so as to radiate in opposite directions. The centrifugal force is counteracted by two strong springs adjusted to give the proper speed. The eccentric is not keyed on the shaft but turns on a point near the circumference. The governor drum is readily moved from the position of forward to backward gear. The governor weights when opening from the overrunning of the engine, push the eccentric towards mid-gear by means of a curved link, and this controls the engine. The main peculiarity of the piston slide valve is that the metallic packing rings are fixed and flush with the body of the piston for a distance sufficient to cover the ports, while they are elastic through the remaining portion of the circle, thus securing as perfect an admission of steam as is obtained in common slide valves, but with the important advantage of being equilibrium.

The cylinder is 9 in. in diameter, the stroke 12 in., the steam ports 5½ in. by 1 in., about 3 in. long, the lap 7/8 in., the exhaust ports 3½ in. by 1¾ in. It is surrounded by a steam jacket, which drains to the steam boiler. The first cover is also steam jacketed, the back cover contains a hollow space, but not communicating with the boiler for convenience of removal when the steam is up. The steam is supplied to the cylinder independently of the jacket by means of an internal pipe perforated near the smoke box end.

The boiler has fifty-five tubes, 1 7/8 in. in diameter, 6 ft. 2½ in. long between the tube plates. The fire-grate is three and a-half square feet in area, total heating surface of 184.25 square feet. The exhaust is carried outside the boiler to the smoke-box, its emission taking place through a 2 7/8 in. orifice just above the upper row of tubes. The communication with the exhaust is so arranged that sufficient exhaust steam is condensed to heat the water in the feed tank to a temperature from 140 to 180 degrees.

At the recent trials, this engine made its longest run yet made without separate expansion valves and it is well observed that the quantity of water used per dynamometrical horse-power per hour is much the same as that of the best engines with double valves. The engine is not intended to be a racing engine proper, but only as an exact specimen of work turned out for general use. |

|

1872 E. R. & F. Turner Portable Steam Engine (Side View)

1872 E. R. & F. Turner Portable Steam Engine (Side View)

1872 E. R. & F. Turner Portable Steam Engine (Top View)

1872 E. R. & F. Turner Portable Steam Engine (Top View)

1872 E. R. & F. Turner Portable Steam Engine (Rear & Section Views)

1872 E. R. & F. Turner Portable Steam Engine (Rear & Section Views)

|

|