|

Title: |

1894 Article-Buffalo Woodworking Machine Co.-Segment Resawing Machine |

|

Source: |

The Woodworker, V13, April 1894, pg. 24 |

|

Insert Date: |

10/13/2016 8:11:09 PM |

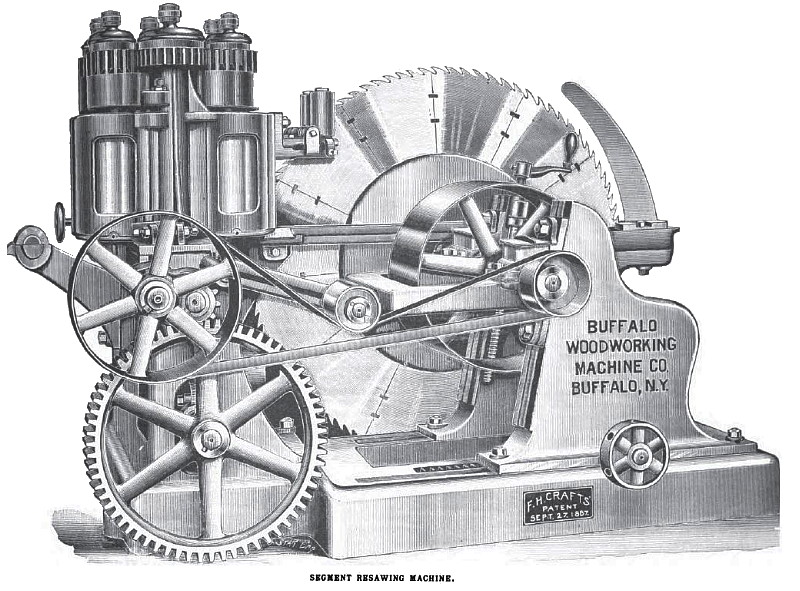

SEGMENT RESAWING MACHINE.

The careful observer will discover by the appended engraving that a radical departure has been made in the construction of segment resawing machines. The demand for a strong, heavy, durable machine, that would stand up to its work in cottonwood, yellow pine and hard wood, led to the production of this machine. The beauty of this tool is its compactness. The metal is placed where it will do the most good. The foundation is a heavy bed-plate, cast in one piece, with the component parts securely bolted thereto. The saw arbor is of steel, 2½ inches in diameter, and runs in patent journal boxes. The boxes are heavily yoked together, and will always remain in perfect alignment. The yoke is securely fastened to a heavy pedestal and can be raised or lowered from 12 to 16 inches. This adjustment provides for the reduction of spread of the saw collar, as the collar can be thrown entirely below the table, only leaving sufficient width of the blade above the table to reach through the work that the saw is doing. Practical men will at once see the importance of this improvement, as by the displacement of the collar certain kinds of work can be done that cannot be done on any other machine.

This machine has a new roller-clamping device for preventing stub shorts, which is an important feature. If parties wish to slice up a plank into veneers, the right-hand rolls (after being set to proper thickness) are made rigid. The saw is made straight on left-hand side. The veneer passes on the collared aide, while the thick piece passes on the straight side of saw. Under skillful management saws as thin as 18-gage can be successfully used. The machine can also be used for sawing siding. This is done by placing two pulleys on saw arbor of unequal diameters, the larger pulley being used for resawing, the small one for siding. A 14- inch saw is used for sawing siding. By changing the belts, proper speed is applied to the saws of different diameter.

The pedestal (that carries saw arbor) has rack and pinion adjustment and can be moved to and from the rolls to accommodate wear of saw, or for any change that may be made from large to small saws. The feed rolls are six inches in diameter, and the frames upon which they are hung swings upon a steel pin 1 7/8 inches in diameter; by loosening two bolts the four rolls can be placed at any angle desired. The rolls can be instantly reversed and lumber fed sway from the saw. The saws can be changed in ?ve minutes. This is a great advantage, as when the machine is run constantly as a resaw, two saws can be used, thereby causing no delay to ?le and set the saw, as the operator can take off the dull saw, replace it with a sharp one, and fit the dull one up at his leisure. A gain of about 4,000 feet can be made in ten hours by using two saws. A swing tightener is used on the countershaft to take up slack as the saw is raised or lowered.

These machines are also made without raising or lowering device, in several sizes, by the Buffalo Wood-Working Machine Co., corner Hudson and Seventh streets, Buffalo, N. Y.

Image & article courtesy of Daniel Warner |

|

1894 Buffalo Woodworking Machine Co.-Segment Resawing Machine

1894 Buffalo Woodworking Machine Co.-Segment Resawing Machine

|

|