|

Title: |

1921 Article-Stolp Co., Inc., Automatic Seam Locking Machine |

|

Source: |

Machinery, V28, Sep 1921, pg. 78 |

|

Insert Date: |

6/22/2016 8:00:11 PM |

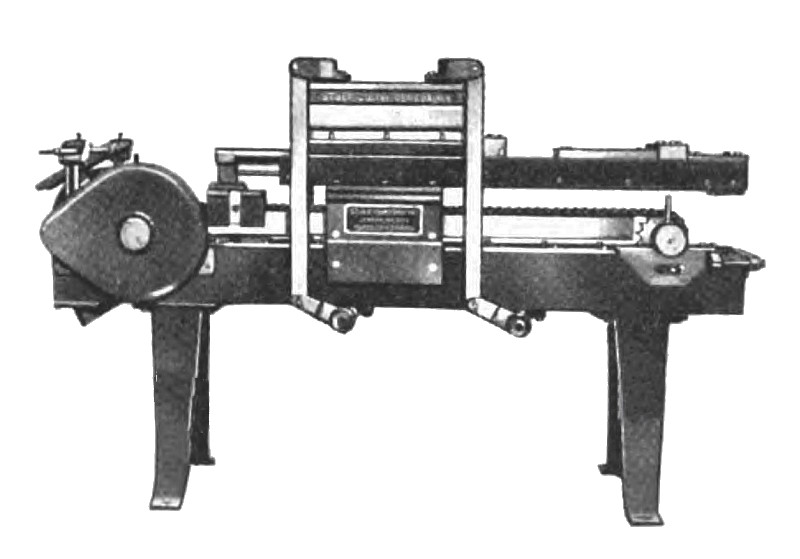

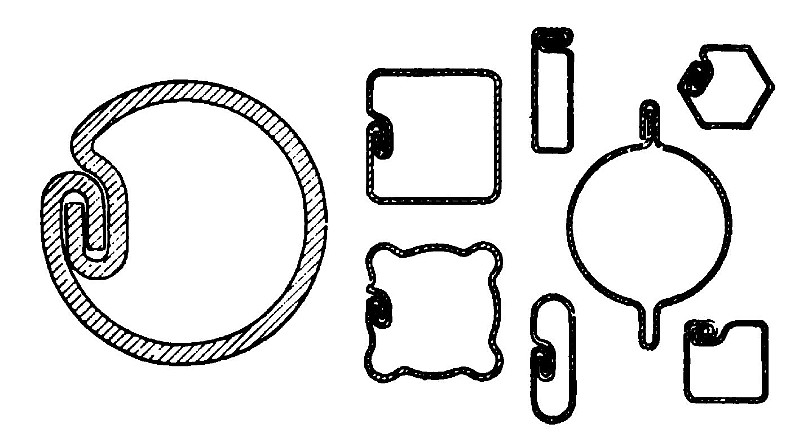

An automatic machine for bending and lock-seaming sheet metal parts from strips or coils of stock by a patented process is illustrated in Fig. 1, while Fig. 2 shows some of the sections which can be formed. This machine is a recent development of the Stolp Co., Inc., Geneva, N. Y. The machine is equipped with a self-feeding attachment. The stock, on being fed into the machine, is first pressed into a U-shape by a punch, after which a round mandrel enters the blank from the rear and pushes it endwise through lock-seaming dies. The mandrel is fastened to a crosshead connected to a chain. This chain runs continuously and carries the crosshead back and forth the entire length of the frame.

As the mandrel reaches the farthest back position, the if-shaped punch descends and presses the blank into a position in line with the mandrel. The mandrel enters the blank as the punch leaves it and carries the work forward as previously explained. The lock-seaming dies have no moving parts, but they are so constructed that the blank is closed and the lock-seam produced in one operation. The machine will lock-seam taper tubes within certain limits. Among the many parts which can be produced on this machine are tubes for mufflers and radiators, blowers and ventilators. |

|

1921 Stolp Co., Inc., Automatic Seam Locking Machine

1921 Stolp Co., Inc., Automatic Seam Locking Machine

1921 Stolp Co., Inc., Automatic Seam Locking Machine (Samples of Lock Joint)

1921 Stolp Co., Inc., Automatic Seam Locking Machine (Samples of Lock Joint)

|

|