|

Title: |

1921 Article-Jackson Machine Tool Co., -#6A & #10A Vertical Milling Machines |

|

Source: |

Machinery, V28, Oct 1921, pg. 161 |

|

Insert Date: |

6/21/2016 7:19:19 PM |

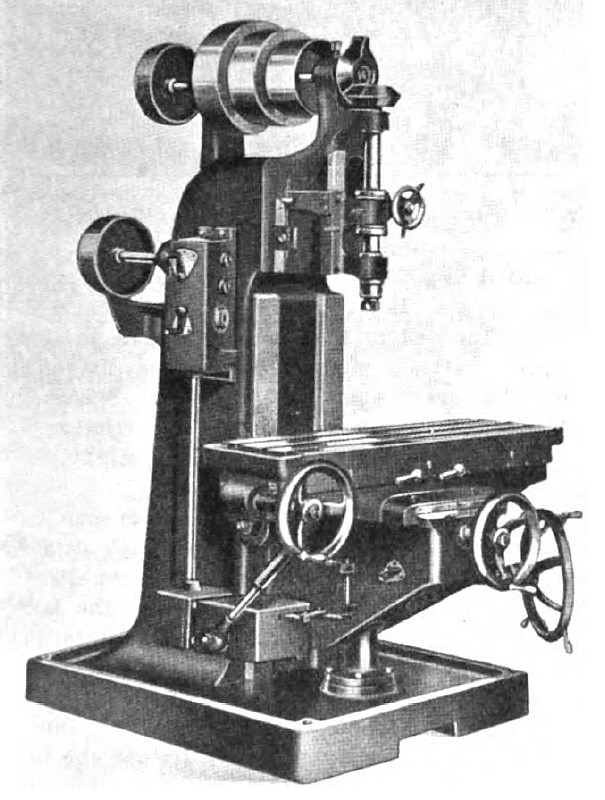

The accompanying illustrations show improved types of vertical-spindle milling machines built by the Jackson Machine Tool Co., Jackson, Mich., for manufacturing and die-sinking purposes. The machine shown in Fig. 1 is known as the No. 6-A, and has power feeds. A machine known as the No. 5-A is similar to the No. 6-A machine except that the feeds are by hand, the table surface is smaller, and some of the traverses are less. The machines are very much the same as the Nos. 5 and 6 Jackson die-slnkers, but they are not equipped with a cherrying attachment.

To facilitate operation, the spindle has a vertical movement, manipulated by hand through a mechanism permitting both hand feed and rapid traverse. Near the lower end of the spindle is a vertical sliding housing, which carries both the lower main spindle bearing and the thrust bearing and is operated for a slow feed by the hand-wheel shown at the right. The rapid traverse is obtained through a four-spoke pilot wheel located near the hand-wheel. The slow feed is quickly engaged or disengaged by a slight turn of a small knurled hand-wheel, and when the slow feed is disengaged, the rapid traverse is free to operate. The spindle and housing are counterbalanced by a weight inside the column, which is slightly greater than the weight of the spindle and attached parts, in order that all lost motion between the cutting tool and the hand-wheel may be taken up. A micrometer stop is provided for determining the depth of cut and the vertical position of the spindle. The spindle housing may be clamped in position for a longitudinal or a transverse cut when the proper depth is once obtained.

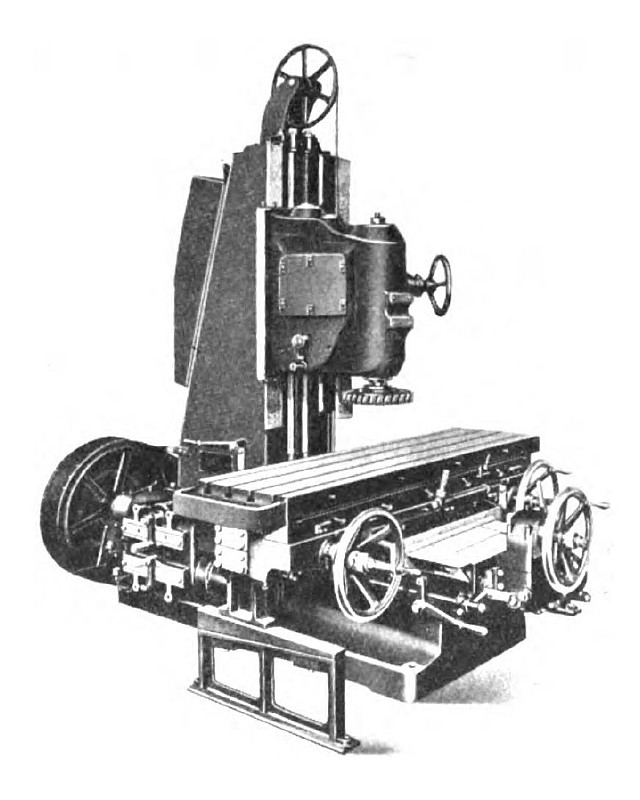

Fig. 2 shows the No. 10-A milling machine. Another machine known as the No. 10-B is similar to the No. 10-A, except that the latter has a table and cross-rail feed ranging from 0.001 to 0.015 inch per revolution of the spindle while the No. 10-B machine has a range of feeds from 5/16 inch to 16 inches per minute, regardless of the spindle speed. These milling machines are practically the same as the No. 10 die-sinker, the only difference being that they are provided with a head containing a heavy vertical milling spindle, whereas the die-sinker is equipped with a head containing a vertical spindle and a cherrying mechanism. Inside the milling machine head is a back-gear arrangement, whereby thirteen changes of spindle speeds ranging from 8½ to 310 revolutions per minute are obtained. A pull-pin lever on the head provides means for quickly shifting from direct to back-gear. All other speeds are secured through the change-gear box on the left-hand side of the base near the driving pulley.

The lower end of the spindle has an integral flange 6½ inches in diameter and having a ¾-inch keyway running across the face and two holes for securing and driving large cutter-heads. It also has a hole, 13/16 inch in diameter running its entire length for a draw-in bolt, and a No. 13 Brown & Sharpe taper hole at the bottom. All feed changes are controlled at the feed-change box on the right-hand side of the base near the rear end. A circular table 36 inches in diameter may be provided for circular and continuous milling. This table may be used as an attachment on the milling machine table, so that it may be removed when not in use, or it may have its bearing on a specially designed cross-rail. Standard sizes of cutters are made for these machines, the cutters being 4, 6, 8, 10, 12 and 14 inches in diameter. All cutters are made from standard stock and may be used with any cutter-head. The larger heads have backing rings for more securely holding the cutters. |

|

1921 Jackson Machine Tool Co.-#6A Vertical Milling Machine

1921 Jackson Machine Tool Co.-#6A Vertical Milling Machine

1921 Jackson Machine Tool Co.-#10A Vertical Milling Machine

1921 Jackson Machine Tool Co.-#10A Vertical Milling Machine

|

|