|

Title: |

1921 Article-Monarch Machine Tool Co., Small Engine Lathe |

|

Source: |

Machinery, V28, Oct 1921, pg. 153 |

|

Insert Date: |

6/18/2016 1:03:52 PM |

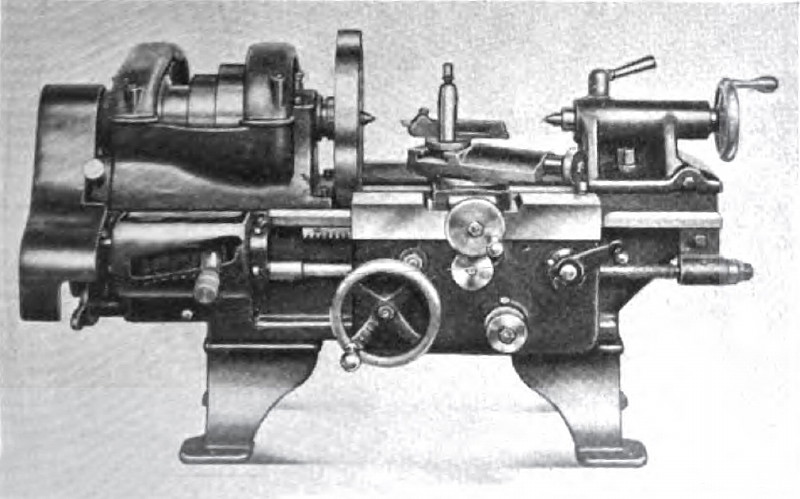

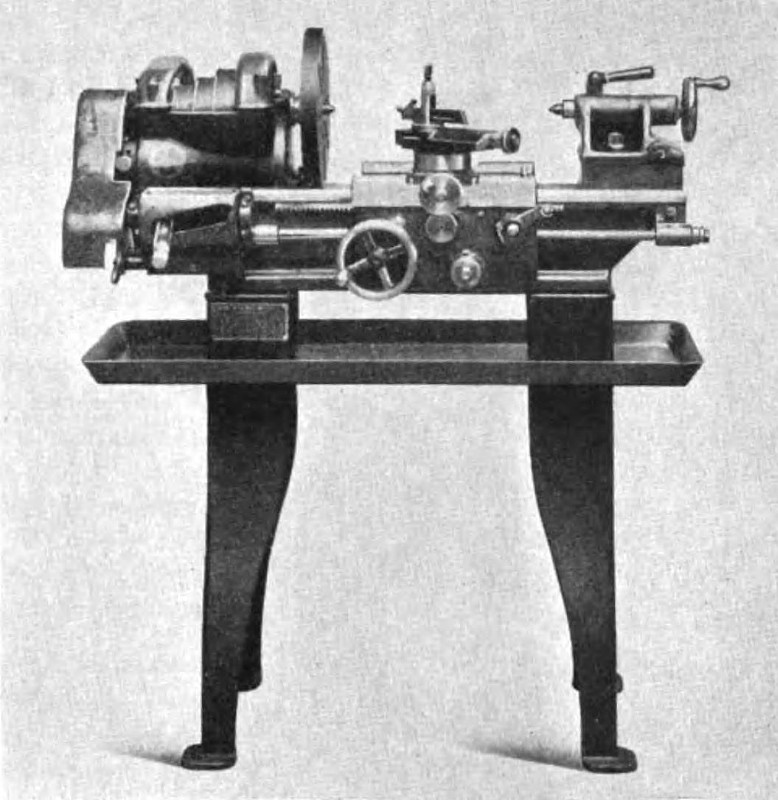

A line of engine lathes of 9- and 11-inch swing, made in bed lengths of from 2½ to 5 feet, has been brought out by the Monarch Machine Tool Co., 209 Oak St., Sidney, Ohio. These machines are sold under the trade name of “Monarch Junior." A 9-inch lathe provided with bench legs is shown in Fig. 1, while Fig. 2 illustrates an 11-inch machine equipped with a chip pan and floor legs. The headstock of these machines is of the solid full-webbed bowl type, and the spindle is made from crucible steel, accurately ground and having a 1 1/16-inch hole running through its entire length. The spindle is driven through a three-step cone pulley and single back-gears. The latter are locked in and out of position by a ball and spring plunger.

The base of the tailstock is graduated to enable accurate settings for taper-turning, and is so arranged that it can be considerably overhung on the bed to give greater distances between centers. Either a full-quick or semi-quick change-gear box can be furnished. With the former, fifty-four changes of threads and feeds are obtainable. The feed and lead-screw reverses are secured through a lever on the headstock. Reversing is done instantly, while the lathe is running. The countershaft is equipped with Edgemont friction clutches and cast-iron hangers provided with ring-oiled bearings.

The compound rest is gibbed throughout, and has large bearing surfaces. The tool-post is provided with a “Mac-It" non-breakable screw. The lead-screw is tested on a Hartness screw-thread comparator. The carriage is drilled and tapped to receive a taper attachment, chasing dial, or chasing stop. The upper knurled hand-wheel on the apron has three positions; when thrown to the left-hand position, the longitudinal feed is engaged, when placed in the right-hand position, the cross-feed is engaged and when placed in the neutral position, the half-nut is engaged. The lower knurled hand-wheel controls the mechanism that operates both the power cross-feed and the longitudinal feed. The regular equipment furnished includes a double-friction countershaft, face-plate, dog plate, center-rest, follow-rest, centers, compound rest and wrenches. A taper attachment and other accessories can be applied by a customer without any machine work or fitting. |

|

1921 Article-Monarch Machine Tool Co., Small 9" Engine Lathe

1921 Article-Monarch Machine Tool Co., Small 9" Engine Lathe

1921 Article-Monarch Machine Tool Co., Monarch 11" Junior Lathe

1921 Article-Monarch Machine Tool Co., Monarch 11" Junior Lathe

|

|