|

Title: |

1921 Article-Ex-Cell-O Tool & Mfg. Co., Parker Grinding, Drilling & Turning Machine |

|

Source: |

Machinery, V28, Dec 1921, pg. 333 |

|

Insert Date: |

6/17/2016 9:56:45 PM |

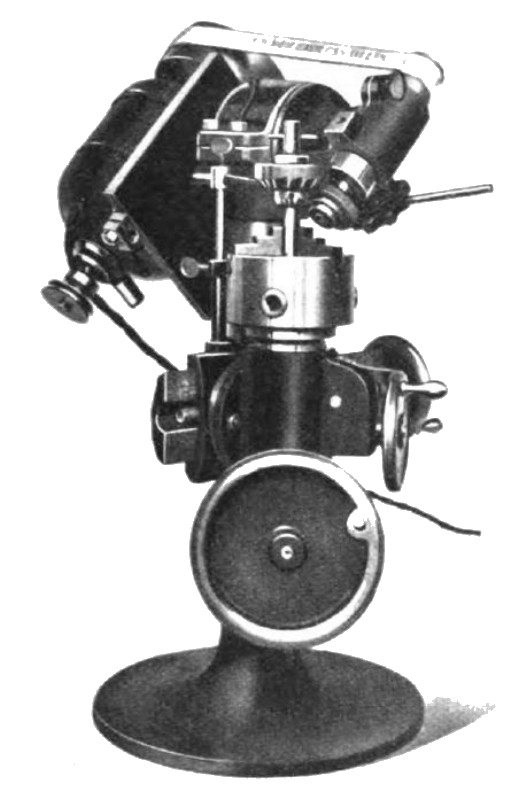

Such operations as the grinding of valve reseating tools, valve cages, commutators, and gears, the sharpening of milling cutters, the drilling and regrooving of pistons, the milling of keyways, and other small machine operations can be readily accomplished by the use of a new bench grinding, drilling and turning machine, which has been brought out by the Ex-Cell-0 Tool & Mfg. Co., 1214 Beaubien St., Detroit, Mich., under the trade name of Parker. From Fig. 1 it will be seen that the upper or grinding spindle is driven by belt from a ¼-horsepower motor, mounted on the same arm as that which supports the spindle on the column. The grinding spindle can be adjusted to various positions to suit angular operations, the motor swiveling with the head. The motor can be furnished to run from any lighting current. A small lever on the right of the grinding spindle head is employed for reciprocating the grinding wheel back and forth across the work.

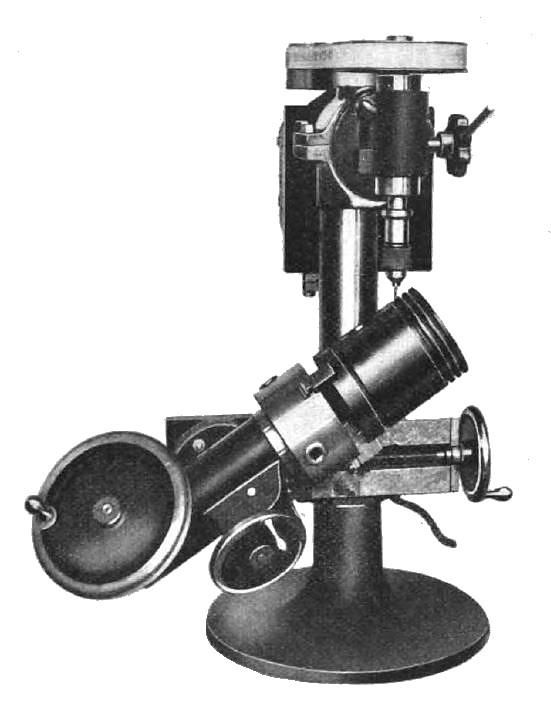

The lower spindle, or work-spindle, is shown equipped with a 4-inch universal scroll chuck, but a 6-inch faceplate is also provided. The work-spindle may also be swiveled to any desired angle, as will be apparent by referring to Fig. 2, in which the upper spindle is in a vertical position and provided with a chuck and drill for drilling holes at an angle through the wall of an automobile piston. Both the swiveling members of the upper and lower spindle heads are graduated to enable accurate adjustments. In Fig. 2 it will also be seen that a large pulley has been mounted on the upper spindle instead of the small pulley seen in Fig. 1. A larger pulley is necessary in drilling and milling operations for reducing the speed of the spindle to suit these classes of operations. The lower spindle may also be revolved by a hand-wheel which is driven by a V-shaped belt, the hand-wheel being provided with a groove around its periphery for this purpose. This V-shaped belt is connected to the small pulley mounted on the shaft extending from the lower end of the motor, previously referred to in connection with Fig. 1. The proper tension is maintained on this driving belt by means of a double idler pulley fastened to a spring on an adjustable rod secured to the motor support. This arrangement is not illustrated.

The upper spindle is equipped with ball bearings, while the work-spindle has a straight bearing which extends its full length and also has a %-inch 45-degree angle thrust bearing. Both external and internal grinding operations can be performed on the machine, and an idea of its grinding range can be obtained from the fact that it is used for grinding the outside cylindrical surfaces of automobile pistons and for grinding holes as small as 5/16 inch in diameter. The regrooving of pistons and the turning of small armatures can be accomplished by mounting a tool in the lug at the left of the grinding spindle bearing. An overhanging center bracket can be furnished. The lower spindle head has a horizontal travel of 7 inches and a vertical movement of 8¾ inches. The machine has an over-all height of 24 inches and weighs about 135 pounds. |

|

1921 Ex-Cell-O Tool & Mfg. Co., Parker Grinding, Drilling & Turning Machine

1921 Ex-Cell-O Tool & Mfg. Co., Parker Grinding, Drilling & Turning Machine

1921 Ex-Cell-O Tool & Mfg. Co., Parker Grinding, Drilling & Turning Machine

1921 Ex-Cell-O Tool & Mfg. Co., Parker Grinding, Drilling & Turning Machine

|

|