Image

|

Title: |

1921 Article-Betts Machine Co., 52 in. Boring Machine |

|

Source: |

Machinery, V28, Oct 1921, pg. 151 |

|

Insert Date: |

6/14/2016 7:05:50 PM |

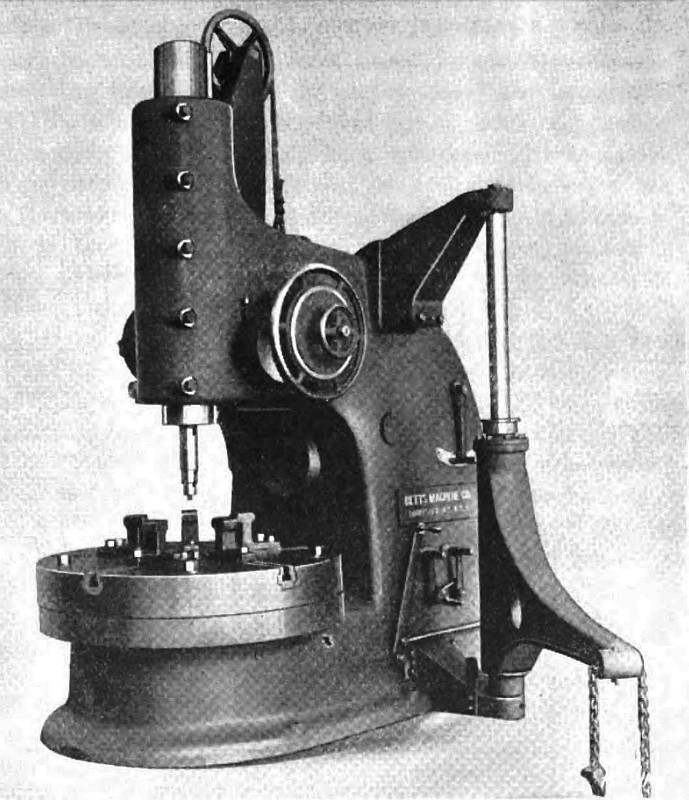

A 52-inch car-wheel boring and facing machine has been added to the line of heavy railway machines manufactured by the Betts Machine Co., 400 Blossom Road, Rochester, N. Y. This machine is intended to cover the requirements of both manufacturing and repair shops. The bed and frame are one massive casting, and the entire machine is designed to withstand high stresses. Special attention has been given to simplicity of operation. The machine may be driven by a single pulley or by being direct-connected to a constant or variable-speed motor. The necessary speed changes to given faceplate revolutions of 10.2, 13.9, 20.4 and 30.7 per minute are obtained by means of hardened sliding steel gears running in oil. The two short levers seen on the frame in the accompanying illustration are used for obtaining the four speed changes. These levers are interlocked so that no two sets of gears can be placed in mesh at the same time.

The table revolves on a wide bearing and has a large spindle running in a bronze-hushed bearing. This spindle is provided with a locking collar at the lower end to prevent it from lifting. The table is equipped with a five-jaw chuck that is both universal and independent, and is readily adjustable for wheels of any size within the range of the machine. Five stations are provided for operating this chuck so that one of them will be convenient to the operator, regardless of where the table is stopped. The long lever seen just to the right of the table is used for operating a friction clutch and brake. whereby the machine may be started and stopped instantly.

Six automatic boring and facing feeds are obtained by means of a two-step cone pulley and sliding steel gears so arranged that the feeds can be changed instantly from roughing to finishing. The boring ram has an easy hand adjustment that is facilitated by a counterweight within the machine. When so desired, the machine can be equipped with a facing ram on which the facing head is supported close to the cut. This ram is of such construction that it can he slid out of the way when chucking wheels of large diameter. The machine is regularly equipped with a quick-acting air-operated crane for loading and unloading the car wheels. This crane can also be arranged to be driven by an individual motor or by belt. All control levers and the hand adjustment of the boring ram are within easy reach of the operator from one position. |

|

1921 Betts Machine Co., 52 in. Boring Machine

1921 Betts Machine Co., 52 in. Boring Machine

|

|

|

|