|

Title: |

1907 Article-Johnston Oil Engine Co., 200 HP Crude Oil Engine |

|

Source: |

Machinery Magazine, V13, Aug 1907, pg. 464 |

|

Insert Date: |

3/3/2016 5:29:54 PM |

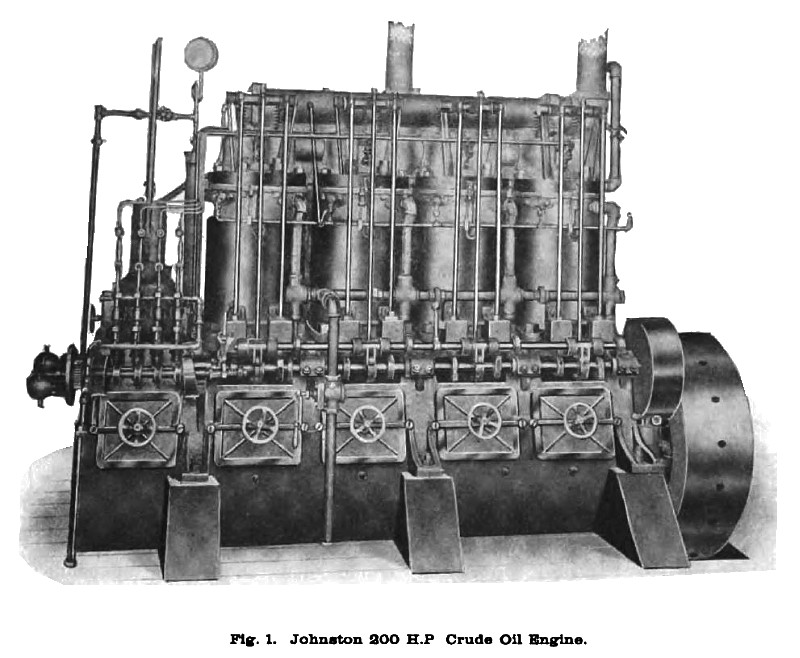

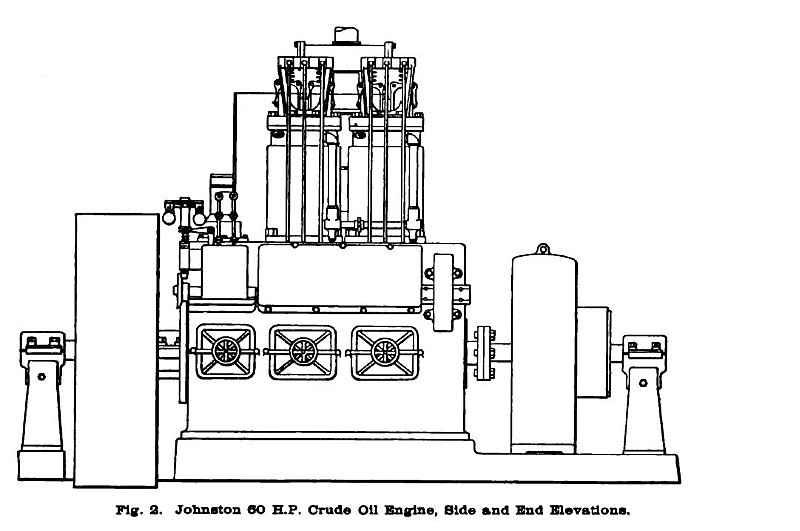

The Johnston crude oil engine, shown in Figs. 1, 2 and 3, operates on a cycle somewhat similar to that of the Diesel engine, but is without its disadvantages. The compression pressure usually carried is 150 pounds per square inch, but any compression from 90 to 300 or 400 pounds may be used if so desired. The fuel is injected in a spray at the end of the compression stroke, and is immediately ignited and burned as it enters the cylinder. The ignition is independent of the compression, and is caused by a plate of special alloy fastened to the end of the piston; this plate is maintained at a high temperature by the recurrent charges of oil burning in the cylinder. The first few charges are ignited by a hot thimble, which is heated externally for two or three minutes before starting the engine. When the engine is once started, no further heating is required.

The oil is broken up by means of a specially designed spraying device and compressed air. A two-stage air-pump is attached to the engine, which maintains the air pressure at any desired point, usually 300 to 400 pounds. Storage tanks are supplied with the engine, and compressed air is used for starting, the start without cranking being certain when instructions are followed. The governor acts on the oil-pump and controls the amount of oil injected into the cylinder each working stroke. As the compression pressure remains practically constant under all loads, the economy, when running light, is much better than in the ordinary throttling gas engines.

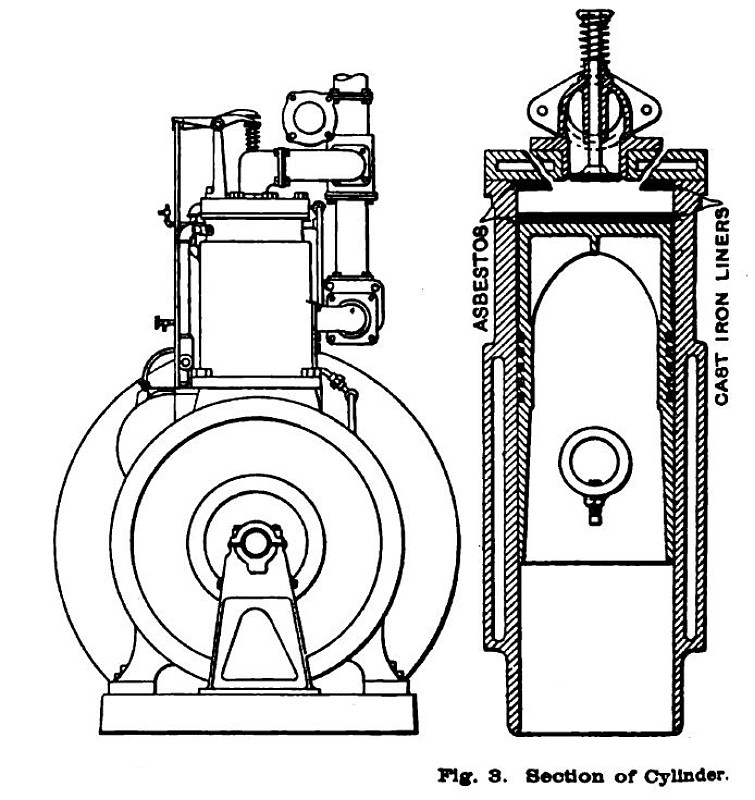

One of the principal reasons for the success of this engine is the use of a “hot” combustion chamber. Inasmuch as no air is mixed with the fuel charge until the proper time for ignition has arrived, it is impossible for pre-ignition to take place. Hence there is no limit to the cylinder temperature or compression, so far as pre-ignition is concerned. This is an important feature of economy, as high working temperatures are possible—temperatures that are impossible in explosive charge engines. These, in fact, have to waste a large percentage of their heat in water-jackets designed to keep the cylinder walls below the igniting point of the charge. The Johnston engine is so constructed that during the injection and burning of the oil and the early part of the expansion stroke no water-jacketed surfaces are exposed to the charge. The whole interior of the combustion chamber is at such a high temperature that there is no tendency for tar or carbon to accumulate, and after a long run the interior of the combustion chamber will be found perfectly clean, more so, in fact, than if the engine had been run only a few minutes. In very short runs, the temperature does not rise high enough to burn the walls perfectly clean, but even on no load there is no accumulation of carbon.

The question which immediately springs up in the mind of the engineer when hot cylinders are mentioned, is: “What about the lubrication?” By referring to the section, Fig. 3, the method of providing hot surfaces for combustion chamber and cool surfaces for the piston and piston rings may be seen. The piston proper works in a water-jacketed cylinder in the usual way, but the piston is constructed with an extension which is 1/16 inch smaller in diameter than the bore of the cylinder, and hence never comes in contact with it. No matter how hot the piston extension may become, no harm can result, as there is no contact or fiction between the hot parts. The small ignition plate is the only part that deteriorates, this having to be renewed in from six to twelve months.

Samples of every obtainable oil have been tried in this engine, including many grades of crude oil, crude residues, coal oil, gasoline and benzene, without showing any signs of clogging with any grade fuel, No adjustments whatever are necessary in changing from one fuel to another. A 9 x 12-inch engine has supplied power for the factory of the company for over a year, using the cheapest grade of crude fuel oil, having an average specific gravity of 0.875 and a flash point 170 degrees F. The fuel consumption in small engines, say of 15 H. P., is 34 gallon of any kind of oil per 10 horsepower hours, at normal load.

This engine is the invention of H. Addison Johnston, and is built by the Johnston Oil Engine Co., Ltd., Toronto, Canada. |

|

1907 Johnston Oil Engine Co., 200 HP Crude Oil Engine

1907 Johnston Oil Engine Co., 200 HP Crude Oil Engine

1907 Johnston Oil Engine Co., 200 HP Crude Oil Engine (Side Elevation)

1907 Johnston Oil Engine Co., 200 HP Crude Oil Engine (Side Elevation)

1907 Johnston Oil Engine Co., 200 HP Crude Oil Engine (End Elevation & Cylinder Section

1907 Johnston Oil Engine Co., 200 HP Crude Oil Engine (End Elevation & Cylinder Section

|

|