Image

Manufactured By:

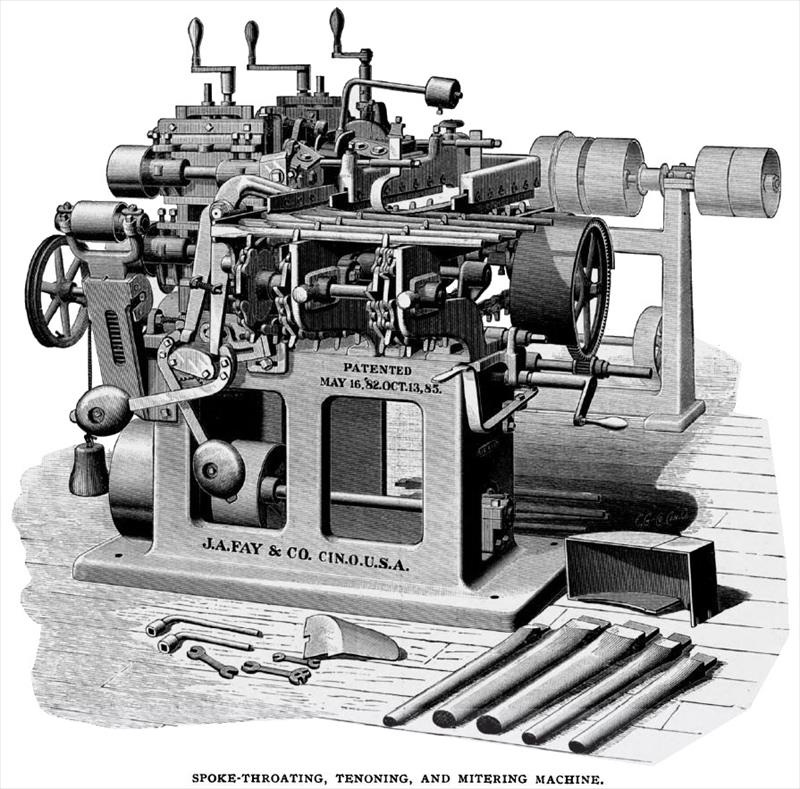

J. A. Fay & Co.

Keene, NH; South Keene, NH; Worcester, MA; Norwich, CT; Cincinnati, OH

|

|

|

Title: |

1897 Article-Fay, J. A., & Co., Spoke-Throating, Tenoning & Mitering Machine |

|

Source: |

The Hub, V39, May 1897, pg. 124 |

|

Insert Date: |

2/26/2016 9:46:51 PM |

For Sarven, other Patent, and Common Spokes. Capacity 12,000 to 18,000.

This machine has been designed to reduce the labor in preparing the turned spokes for the wheel. It is simple in construction, easy to operate and keep in order, and invaluable for the purpose designed.

The three operations of tenoning, mitering, and throating are performed in the most perfect manner on this machine at a single pass, or either operation-tenoning, mitering, or throating can be done separately. Consequently it does the work of three separate machines with one handling of the spoke.

The column is heavy, with broad base. The tenoning and mitering cutter heads and arbors are mounted upon independent frames, both adjustable vertically by a hand-wheel and screw. The throating cutter-heads are located beyond the tenoning cutter-heads, and so arranged as to permit spoke to be fed by the same traveling bed, from the tenoning cutter-heads to the throating-heads, and throated at the proper point.

The throating arbors have a vertical adjustment, to suit different sizes of spokes. A double pressure-bar securely holds the spokes on to the traveling bed, which are provided with drivers, jointed and flexible, so that any inequality of the spoke is provided for. The spokes are fed crosswise, in a straight line through the cutter-heads, the bed lying at a slight angle in order that they may be so tenoned as to secure the proper dish when driven into the wheel-hub. It is supplied with a novel, patent, self-centering attachment, which receives and presents the spokes to the cutters so that the tenons are always formed exactly in the center of the spoke, regardless of inequalities of thickness, or irregularities of turning. After the tenons have been made the tenoned end passes between guides, and is held until the throating is completed, when the spokes drop from the bed at the end of the machine into a rack. A floor countershaft in the rear communicates power to the cutter-heads and feed. The capacity of this machine is to work spokes (common or patent) from 15/16 in. to 3½ in. in diameter. Any shape of throat can be made by this machine, and in the most and perfect and rapid manner. The cuts are made progressively, and the capacity of this machine, with one man, is to tenon and throat from 12,000 to 18,000 buggy spokes per day, according to size of spokes. A shop number is attached to each machine, and numbers on each casting, for reference in ordering. The tight and loose pulleys are 10 x 5 in. and should make 1,000 revolutions. |

|

1897 Fay, J. A., & Co., Spoke-Throating, Tenoning & Mitering Machine

1897 Fay, J. A., & Co., Spoke-Throating, Tenoning & Mitering Machine

|

|

|

|