|

Title: |

1909 Article-American Tool Works Co., Sensitive Radial Drill |

|

Source: |

American Engineer & Railroad Journal, V83, May 1909, pg. 210 |

|

Insert Date: |

1/16/2016 5:58:51 PM |

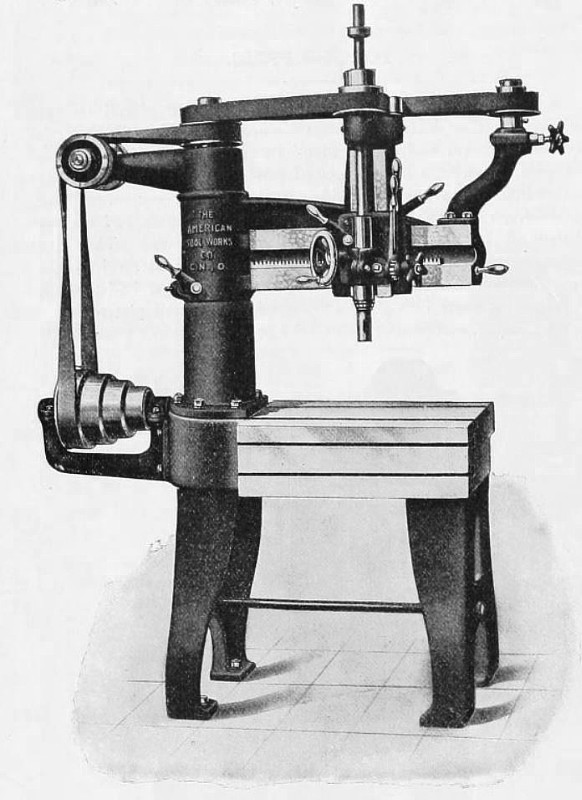

What is believed to be the first sensitive radial drill made in this country is shown in the accompanying illustration. A considerable amount of small drilling can be handled more economically on a tool of this type, where the high speeds are obtained without the use of gearing than on the heavier and more expensive radial drills. This drill is especially adapted for drills up to ¾ in. in diameter. To give some idea of its capacity it may be said that a machine of this type, with a 2 ft. arm, drilled a ¾ in. hole in cast iron, with a feed of .028 in. per revolution or at the rate of 10½ in. a minute, using 3¼ h.p. The head that carries the spindle is adjustable, in and out, on the swinging arm; the work is supported on the stationary table. All the levers controlling the operation are located conveniently for the operator.

The arm is of a parabolic beam and tube section, to give it the proper resistance to the bending and torsional strains. The lower edge of the arm is parallel with the surface of the table. It swings easily on the column and may be securely clamped in any position by the binder lever. The arm does not move vertically, as provision is made on the head for variable heights of work. The head is moved along the arm by a hand wheel through an angular rack and spiral pinion and may be clamped at any point on the arm by the lever shown at the right of the head. The head consists of the main saddle which slides upon the arm and carries an auxiliary sliding head upon a vertical dovetail, thus allowing a vertical movement to the head and doing away with the necessity of elevating or lowering the arm. The vertical slide may be locked by the lever shown at the left of the head.

The double loose pulley at the top of the column is driven from the cone and in turn drives the spindle by a flying belt arrangement, giving a constant tension at all positions of the arm. This tension is adjustable by shifting the position of the idler at the extreme right of the arm. All of the driving and idler pulleys are equipped with specially designed ball bearings. They are dust proof and form a retainer for the lubricant, which needs to be renewed only at long intervals. The spindle has six changes of speed, ranging from 300 to 900 revolutions per minute, and is provided with a ball thrust bearing. It is fed by a long hand lever on a ratchet wheel, the latch handle being self-releasing when in the uppermost position. A convenient star wheel supplies a quick return movement to the spindle.

The table is 35 in. above the floor, a convenient height for the average operator. The top and front sides are fitted with T-slides, planed from the solid. The column is of tubular section, internally ribbed, and extends through the arm into the cap at the top of the drill. This machine with the 2-ft. arm drills to the center of a circle 49 in. outside of the column; the minimum distance from the spindle center to the column is 6¼ in., and the maximum distance from the spindle to the table is 19 in. These machines are also made with 3-ft. arms and can be equipped with a tapping attachment if desired. They are manufactured by file American Tool Works Company, of Cincinnati. |

|

1909 American Tool Works Co., Sensitive Radial Drill

1909 American Tool Works Co., Sensitive Radial Drill

|

|