|

Title: |

1903 Article-James J. Guest & Co., Cutter Grinder |

|

Source: |

Emery Grinding Machinery, 1903, pgs. 113-115 |

|

Insert Date: |

11/24/2015 12:37:18 PM |

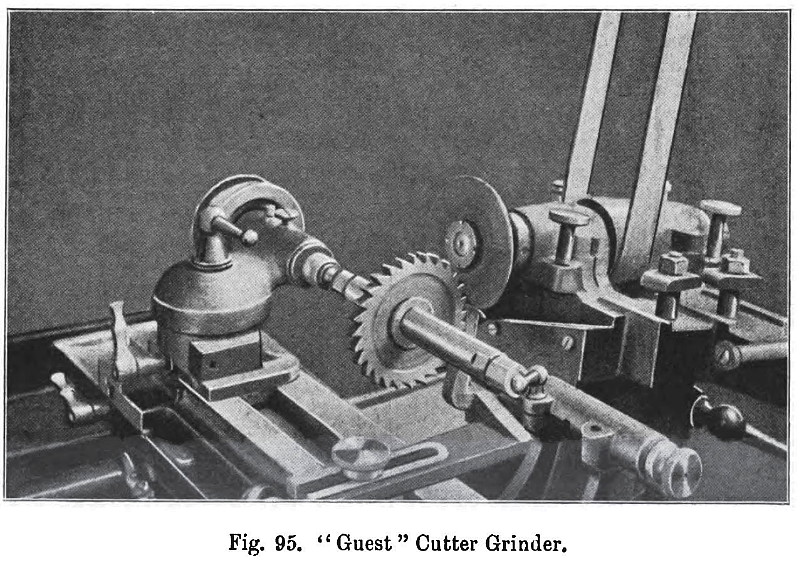

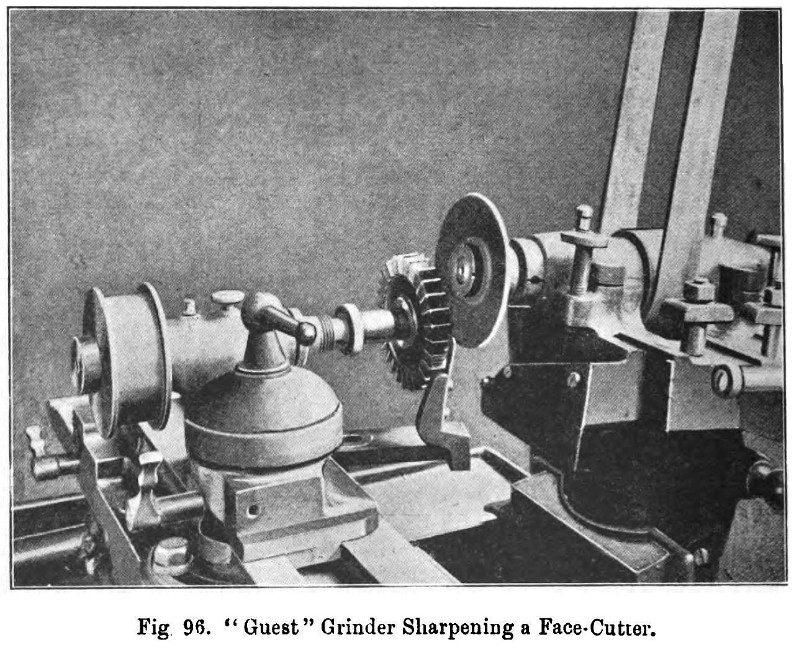

Fig. 95 represents a cutter being ground. The tooth is located by a tooth rest, which acts as a pawl upon the tooth being ground, and fixes it at the same height as the centre. The tangent to the circle enveloping the cutter is then vertical, but the face of the wheel, which is of the cup or dish type, is concave. The edge of the tooth is inclined to this at the desired angle of clearance so as to put the correct clearance on the cutter. Hence, since the edge of the tooth rest is permanently fixed at the same height as the centres, the correct clearance is necessarily ground upon the cutter. It does not matter at what height the knee is set, but it is usually best to set it low and work towards the bottom of the wheel, nor does the diameter or angle of the cutter matter, for if the cutter has a uniformly varying diameter, that is, if it is an angular cutter, the clearance will still be the same. This will also be true when the angle of the cutter is so great that the cutter becomes a face cutter. Fig. 96 represents a cutter of this kind in the process of being ground.

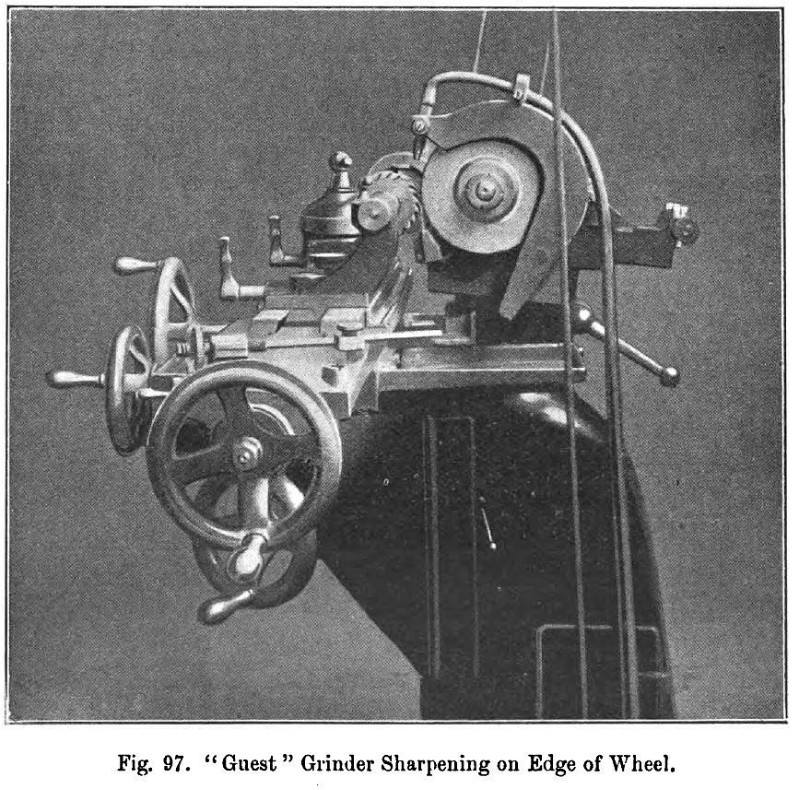

Sometimes, however, it is best to grind a cutter on the edge of the wheel, as is represented in fig. 97. To grind a cutter in this way, place the tooth rest on the inclined plane formed on the wheel headstock, and set it so that its edge is just outside the grinding wheel. Place the same tooth rest upon the table and adjust the knee until the edges meet. The table is then set for producing the correct clearance, the tooth rest removed, and the cutter set as shown in the figure. |

|

1903 James J. Guest & Co., Cutter Grinder

1903 James J. Guest & Co., Cutter Grinder

1903 James J. Guest & Co., Cutter Grinder (Sharpening a Face-Cutter)

1903 James J. Guest & Co., Cutter Grinder (Sharpening a Face-Cutter)

1903 James J. Guest & Co., Cutter Grinder (Sharpening on Edge of Wheel)

1903 James J. Guest & Co., Cutter Grinder (Sharpening on Edge of Wheel)

|

|