|

Title: |

1920 Article-Marshalltown Mfg. Co., Boiler Plate Milling Machine |

|

Source: |

American Machinist, 26 Aug 1920, pg. 432 |

|

Insert Date: |

11/16/2015 8:48:59 PM |

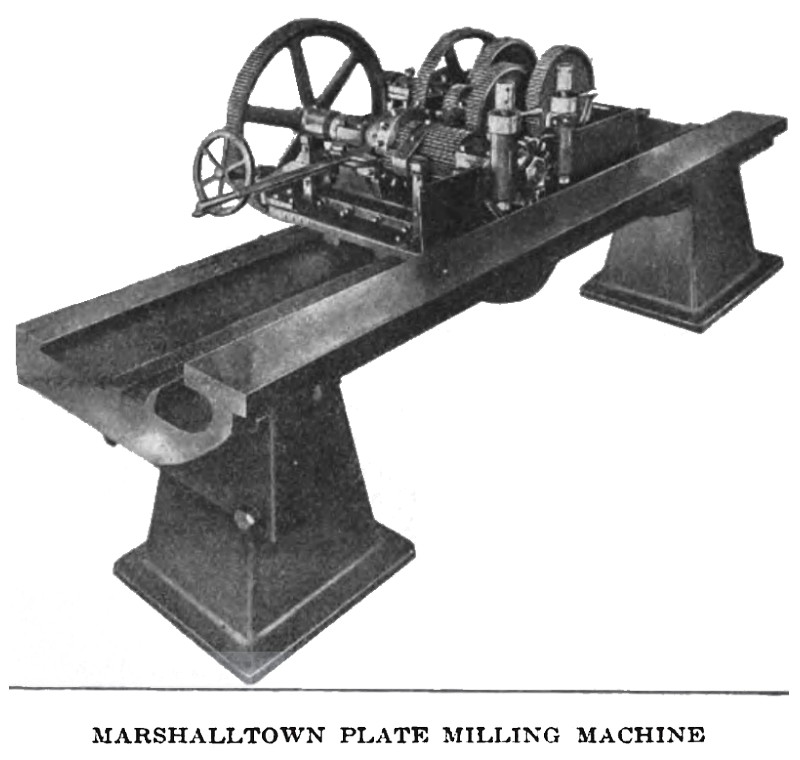

Marshalltown Plate Milling Machine

The illustration shows a plate milling machine built by the Marshalltown Manufacturing Co., Marshalltown, Iowa. It is intended for beveling and squaring the edges of boiler plates up to 1-in. thickness, the full length of the sheet. Curves can also be milled. The machine consists of a bed mounted on pedestals and carrying a sliding head containing all the operating mechanism. A 5-hp. motor on the head is geared to the spindle, driving the feed as well as the spindle. Both a friction slip and a quick return are provided in the feed mechanism. An inserted-tooth cutter 8½ x 2 ½ in. is used, the end thrust on the spindle being taken by ball bearings. A traverse of 2 in. is provided for the spindle, so that offset edges may be machined. Rollers are provided on both sides of the cutter for holding down the work. The cutting lubricant is circulated by means of a motor-driven pump located in a case at the end of the bed. The machine is built in four sizes to mill lengths up to 8, 12, 16 or 24 ft. The weights range from 8,600 to 14,765 lb. |

|

1920 Marshalltown Mfg. Co., Boiler Plate Milling Machine

1920 Marshalltown Mfg. Co., Boiler Plate Milling Machine

|

|