|

Title: |

1874 article - history and description of some metal-working machines |

|

Source: |

"Manufacturer & Builder". Vol. 6 No. 6, June 1874, p. 127 |

|

Insert Date: |

10/8/2007 11:09:47 PM |

The Manufacture of Special Machinery

It is interesting to trace the history of our manufacturing establishments, and see what vicissitudes and changes have attended many of them, until by contributions from successive owners, or by changes of times or employment, or by judicious management, the latest holder acquires an enviable position in the business community. Such has been the case with the works of Messrs. Jones, Lamson & Co., of Windsor, Vt. This establishes was begun by Messrs. Kendall & Lawrence, custom gun-smiths. In 1845 they made 10,000 rifles for the United States army, under the firm name of Robbins, Kendall & Lawrence; two years later, they were incorporated as the Robbins & Lawrence Co., and in consequence of the excellence of arms exhibited by them at the first World's Fair in England, they were employed by that government to furnish a set of machinery for the Enfield Armory, and 20,000 Enfield rifles. This machinery was the first introduced into that country for making guns with parts interchangeable upon the American plan. They also made a full set of machinery and tools for the Sharpe's Rifle Co., Hartford, Ct. By a complication of circumstances the Robbins & Lawrence Co. failed in 1856.

The works were purchased about 1861 by Lamson Goodnow & Yale, and were employed by them and their successors, the Windsor Manufacturing Co., in manufacturing machinists' tools and arms. During the late war, more than 60,000 guns were made here. In 1870 the works were purchased by the present firm of Jones, Lamson & Co., who found it profitable to change the main buildings into cotton mills. They are now running in their cotton mills 12,000 spindles and 224 looms, and employ in them and their machine-shop an aggregate of 200 hands.

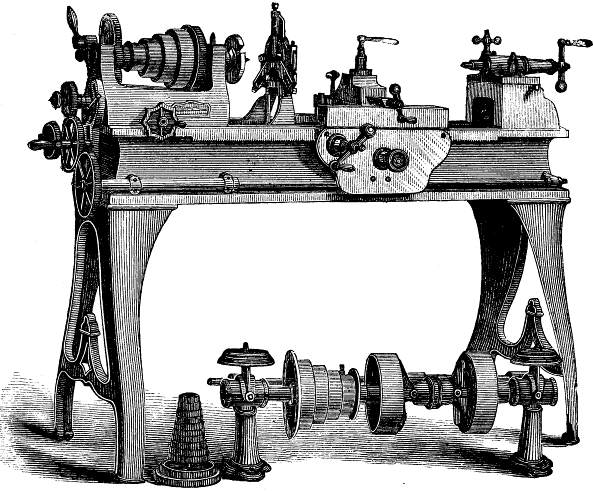

This firm makes it now a peculair business to produce machinists' tools and special machinery for gun-makers, sewing-machine makers, and others, of which we represent two samples in our engravings. Fig. 1 is an engine lathe, of 5 feet bed, 15 inches swing, and adapted for screw cutting. It is a fair representation of other of different of other of different sizes. Attention is called to the following features, which, with the care taken in the workmanship, are believed to make these lathes second to none: The stud quadrant at the end fo the head stock can be shifted and fastened so that the stud gear will operat at pleasure the screw or the feed-rod. The hand wheel in front of head stock may be turned so that, according to its position, it will reverse or stop the stud gear, and consequently the carriage. In this simple and convenient arrangement, a single stud gear answers both for feeding and for cutting right and left hand screws, and as any stud gear may be used in connection with the feed rod, any feed may be obtained for turning. The carriage is gibbed, the tool post bed held down by a spring, and the construction such as to give all the advantages of a weighted carriage. It has an adjustable stop for the cross motion. Any accumulation of dirt in the screw channel is prevented by a suitable clearance hole through which the chips drop when the tool is run back. The friction arrangement for fastening the spindle cone to the large gear is especially convenient. It fastens at any point by turning a screw. The spindle is made tubular, to admit of working wire or bars through a chuck. The screw is steel; while each lathe is provided with a center rest, wrenches and counter-shaft, with friction pulleys or with clutch pulleys.

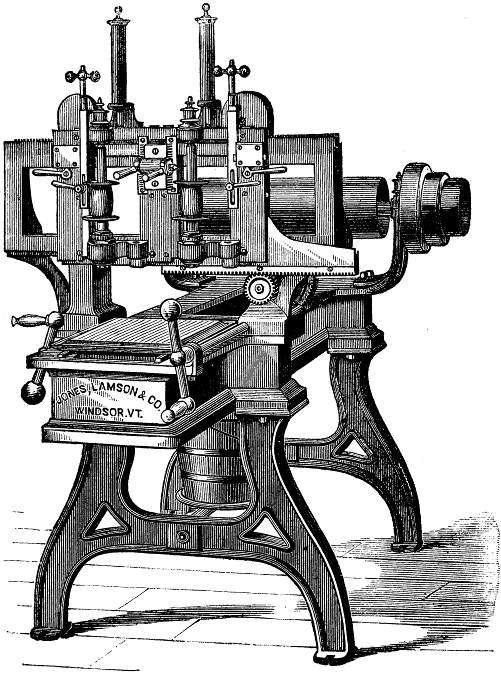

Fig. 2 represents an edging or profiling machine, with two spindles. As is well known, these machines serve for milling around the inside and outside edges of irregular shapes and for surfacing and inside milling. The spindle-carriage has a side motion across the bed, and the platen has a longitudinal motion under the cross-head. A former or profile of the shape required fixed to the platen, and a guide-pin fixed to the carriage act upon each other when the machine is operationed, and by combining the two motions give the cutter any direction required. The spindle slides have a vertical movement in the carriage. The lower spindle bearings shown in the cut are bell shaped, with solid hardened steel boxes and nuts for taking up wear, but when preferred, they are made plain with split boxes. The spindle carriage runs on rollers, which are prevented from sticking and wearing in spots by a rack on top of cross-head and pinions attached to the rollers. The actuating gears of the carriage and platen are made double, and any back play from wear is taken up positively, and not by friction. The platen and bed have channels to convey oil or soda-water into a pail under the machine. The following are the principal dimensions: cross movement of spindle carriage, 19 inches; longitudinal movement of platen, 15 inches; vertical movement of spindle, 3 1/2 inches; diameter of spindle at lower bearing, 1 1/2 inches; length of platen, 15 inches; width of platen, 12 inches; usual distance from platen to bottom of carriage, 5 inches; while it weighs 2,000 pounds. These machines are designed by and constructed under the superindendence of Mr. H. D. Stone, who has been connected with the works from their beginning. He is the inventor of the revolving-head screw machine or turret lathe, so extensively known and used. The introduction of these machines has revolutionized the process of machine screw-making, and a description of them and their adaptability to other work, and of some late improvements, wil be the subject of a future article in these columns.

The following is a partial list of the machines made by this firm: iron planers, shaping machines or compound planers, engine lathes, hand lathes, chucking lathes (3 spindles,) chucking lathes (6 spindles,) broaching machines, hot trimming machines, common milling machines, index milling machines, universal milling machines, arm milling machines, clamp milling machines, screw milling machines (6 sizes,) small trip hammers (oron beds,) screw slotting machines, tapping machines, press drills (4 spindles,) pres drills (3 spindles,) die-sinking machines, edging or profiling machines, polishing machines (Ball's patent,) bullet lubricating machines (Ball's patent,) Lane's patent circular-saw mills, Dutcher looms, etc. It is with satisfaction that we can state that all these machines are of the same solid and reliable workmanship as those here represented. |

|

Fig. 1. Improved screw-cutting engine lathe

Fig. 1. Improved screw-cutting engine lathe

Fig. 2. Edging or profiling machine, with two spindles.

Fig. 2. Edging or profiling machine, with two spindles.

|

|