|

Title: |

1856 Article-William Muir & Co., Slide Lathe |

|

Source: |

The Engineer, 03 Oct 1856, pg. 540 |

|

Insert Date: |

10/15/2015 7:51:46 PM |

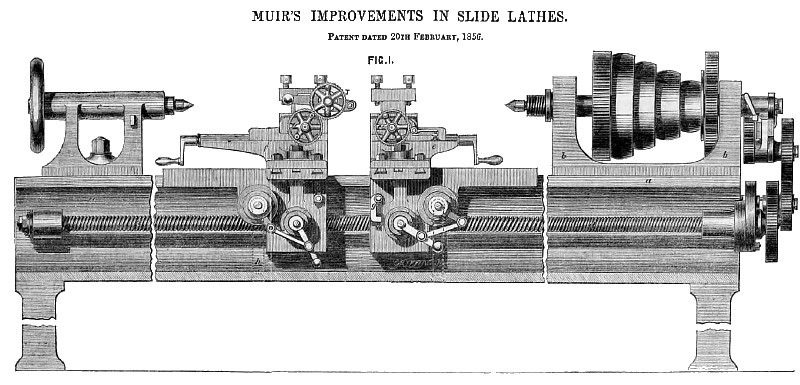

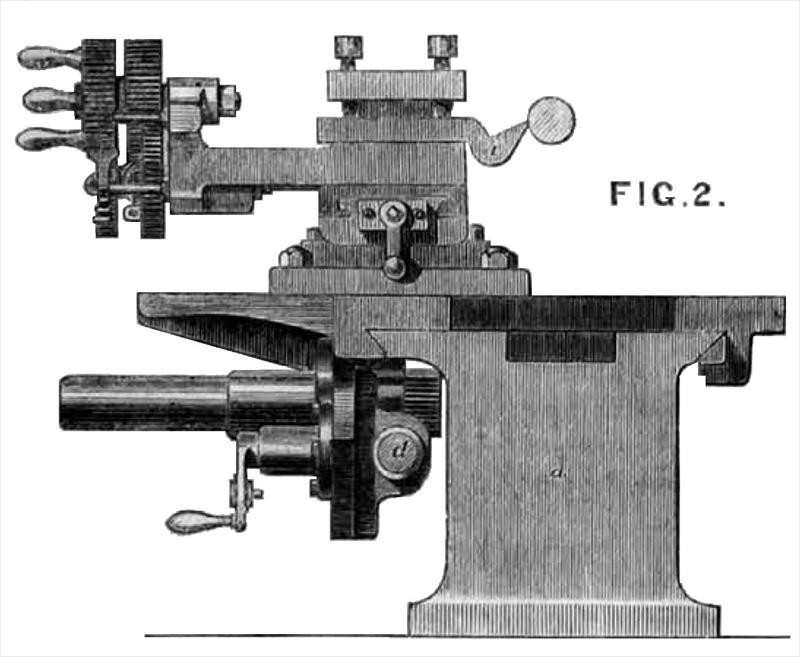

The nature of this invention consists in applying one or more additional slide rests to slide lathes of the ordinary construction, to economize time and labour in taming or screw cutting. Figure 1 is an elevation of a slide lathe of the ordinary construction, to which the improvements are applied; and Figure 2 is an end view. a represents the bed of the slide lathe; b, the fast headstock; c, the loose headstock: and d, the screw by which motion is communicated to the ordinary slide rest e and to the additional slide rest f.

Although only one additional slide rest is shown, it is evident that in long slide lathes two or more additional slide rests may be employed. In Fig. 1 the rests e and f are shown at a certain distance apart. The workman, by turning either of the handles h, can regulate the distance between the rests, each of the said handles being in connection with a pinion gearing into the main screw d in the usual manner; but as seen as the distance between the rests is determined, both the rests are moved simultaneously along the bed by the main screw d.

Each slide rest is furnished with a back stay and with a cutting tool, as shown in at i in Figure 2; and as each tool is capable of being adjusted laterally and for the depth of the cut independently of the other or others, it is evident that in turning or sliding a shaft the first tool will be giving the rough cut, while the other or others is or are performing the finishing cut; by this means a considerable saving in time and labour is effected.

A modification may he made from the above, which is particularly applicable for screw cutting. The tool holders in this case are connected by a pinion, which revolves on a stud fixed to the slide rest; this pinion, when the rests are connected together, gears into both the pinions attached to the screws of the tool holders, consequently, when the attendant turns rounds either of the three pinions, the requisite motion for regulating the depth of the cut or for inserting or withdrawing the tools is performed simultaneously.

The depth of the cut is capable of being adjusted in each tool independently of the other by a worm and worm wheel. The worm on being turned round gives motion to the worm wheel, which is fast on the screw acting on the tool holder: consequently, by turning the said screw round, the depth of the cut is increased or diminished. |

|

1856 William Muir & Co., Slide Lathe

1856 William Muir & Co., Slide Lathe

1856 William Muir & Co., Slide Lathe (End View)

1856 William Muir & Co., Slide Lathe (End View)

|

|