|

Title: |

1905 Article-Hanchett Swage Works, Band Saw Sharpener |

|

Source: |

Wood Craft, Nov 1905, pg 95 |

|

Insert Date: |

10/1/2015 1:29:10 PM |

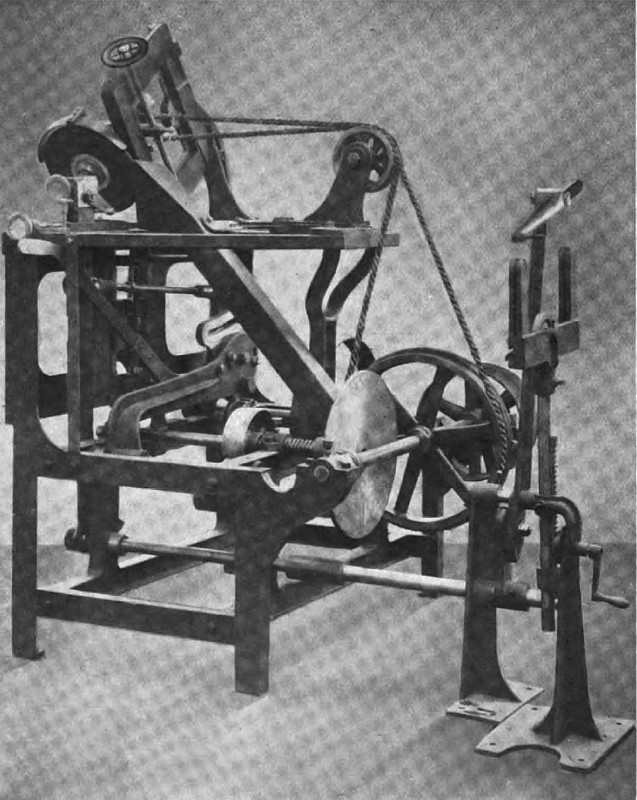

A Band-Saw Sharpener

The proprietors of the Hanchett Swage Works, Big Rapids, Mich., are best known as pioneers in the manufacture of saw swages, in fact it has confidently been claimed that 75 per cent of the swages in the country are of this make. The progress of the enterprise quite naturally led to the consideration of other filing room equipment to go with the swages. When Mr. Hanchett was in Seattle last winter, the manager of the Simonds Mfg. Co. called his attention to a new machine for sharpening saws. This tool was the invention of a Mr. Hedstrom, formerly a foreman with the Covel Mfg. Co. Mr. Hedstrom had had excellent opportunities for studying saw filing equipment and the machine here illustrated embodies the result of his research.

There is one thing about the modern automatic saw sharpener which is difficult to control; that is vibration. It is of first importance that a saw sharpener in action shall as nearly as possible be free from vibration. If this condition does not obtain in practice, then the result is an unevenly ground tooth with consequent loss in quality and quantity of work from the saw. Most manufacturers meet the trouble by making their machines of heavy box construction on the anvil principle to absorb vibration. In the majority of cases the brackets and pulleys are on top of the machine and these are connected with the emery wheel, the mechanism being driven direct from the countershaft by screws, gears, chains, etc.

The machine seen in the halftone lacks the brackets and gearing already mentioned. It is driven by a rawhide rope, the emery wheel being belted direct from the countershaft by a rope passing over the top of the machine by way of idlers. The feed is run by a friction and disk. Both feed and drive are noiseless and smooth running.

The cam adjustment also is different. Commonly a new cam form must be furnished for every shape of tooth. These are exchanged whenever the shape of the tooth changes. As a rule the mill owner purchases several of them. The Hanchett machine has an adjustable cam, the one cam being sufficient.

This machine is compact and strong. Will sharpen band-saws from 8 to 16 inches wide; has a stroke for a 1¼ to 3 inch tooth. All boxes have oil cups. The bearings are hand scraped, and wearing surfaces have oil chambers. The sheave pulleys give four different speeds for the emery wheel. A long clamp, faced with hardwood and hinged to drop downward to admit or withdraw saw, holds the saw rigid while being fed through the machine, and is clamped at the top of the machine when the saw is in place, to prevent any lateral spring. The emery wheel may be adjusted to any angle, from o to 45 degrees, simply by loosening a setscrew and tilting the head. The gate or slide in the head is made so the wear may be taken up by means of a gib.

The stands for carrying the saw are light. They have a spiral and rack adjustment, a positive stop at any required height without the aid of setscrews. The lips at top of stand diverge and the inside arm is shorter than the other. This, makes it very easy to place the band-saw. The machines deserve a special word of commendation for their workmanlike finish. The machined parts are made skillfully to get the greatest good out of the design. The machines are coated with a dull or fiat black oil proof paint. The hand wheels are nicely polished and nickel plated. |

|

1905 Hanchett Swage Works, Band Saw Sharpener

1905 Hanchett Swage Works, Band Saw Sharpener

|

|