|

Title: |

1880 Article - Colburn's Improved Boring and Spacing Machine |

|

Source: |

October 1880 issue of Manufacturer & Builder |

|

Insert Date: |

12/3/2019 4:35:38 PM |

Article text:

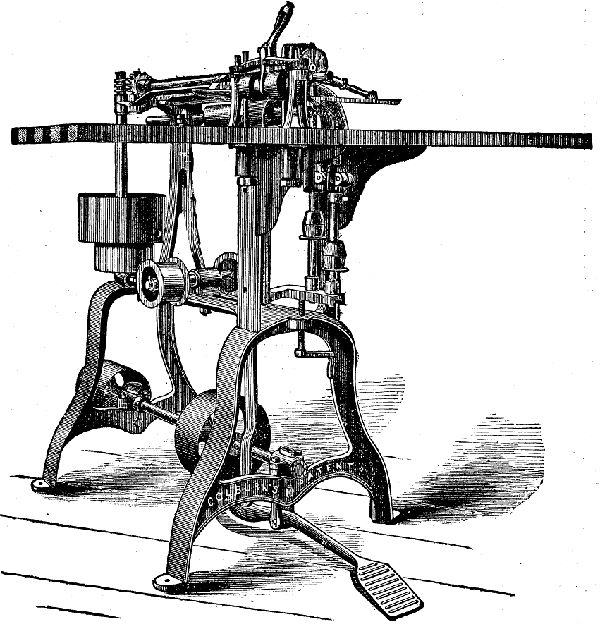

COLBURN'S IMPROVED BORING AND SPACING MACHINE.

The accompanying engraving represents a machine which is well known throughout the United States and Canada as Colburn's boring and spacing machine. The inventor, Mr. L. S. Colburn, himself a practical mechanic, and feeling the need of an improved machine in his own shop, devised the machine originally for his own use; but finding it so well adapted to the wants of manufacturers of rolling blinds, among whom it speedily became popular, he has established a special manufactory for supplying the demand which has sprung up for them. It was originally designed for boring the stiles to rolling blinds exclusively, and for this specialty is claimed to be unequaled by any competing machine. It has been recently improved by the addition of a horizontal arbor and bit, which adapts it to every variety of boring required in a sash, door and blind factory, and is now built from entirely new patterns, with superior workmanship and finish. The two vertical bits are used for blinds only, and will bore, without any previous marking or laying out, 8,000 holes per hour. The stiles, after being jointed, are placed upon the table, with a ratchet or pattern between them, the lower ends of the stiles resting against two blocks, which are securely fastened to the end of the pattern, and are moved over the bits by means of a pawl working in the notches of the pattern. It spaces its own work with perfect accuracy, at any distance apart, from 1 to 1 7/8 inches, and bores the entire length of the stile without stopping, hence no time is lost in stopping the machine to pass the lock-rail mortise, nor to lay out the work, as the boring is always done before mortising. The mortises are marked on the edge of the stile while the machine is in operation, from corresponding marks on the edge of a thin strip which has been previously laid off and tacked to the side of the pattern, and which can be replaced with any length required. The boring being done from the under side of the stile, the chips drop freely from the bits, and leave the holes of a uniform depth, so that the pivot of the slat may work on the end instead of the shoulder, which renders it less liable to bind or to become stuck fast by the paint.

We learn from the manufacturer that hundreds of blind makers, including some of the largest manufacturers in the United States, are using these machines at the present time with entire satisfaction. These machines were all placed on trial, with the guarantee that they should prove satisfactory or be returned; and they have, therefore, achieved their present popularity solely upon their merits. Further details may be obtained on application to the manufacturer, L. S. Colburn, Oberlin, Ohio.

US Patent: 82,803

http://www.datamp.org/patents/displayPatent.php?number=82803&typeCode=0 |

|

IMPROVED BORING AND SPACING MACHINE

IMPROVED BORING AND SPACING MACHINE

|

|