|

Title: |

1918 Article-W. Tasker & Sons, Steam Tractor with Winding Drum |

|

Source: |

The Engineer, 25 Jan 1918, pg. 67 |

|

Insert Date: |

9/2/2015 10:57:30 AM |

A series of tractors, specially designed for agricultural work, are made by W. Tasker and Sons, Limited, of Andover. The series consists of four engines, three of which are practically identical saving in details, while the other only differs from these three in having a larger fire-box, so that straw and other similar fuel may be burned, and in having a rather longer boiler. We propose, therefore, to give one general description of the type, and to draw attention to the points in which the machines differ from one another. The standard tractor, which has the form of an orderly road locomotive, has been designed to comply with the Motor Car Acts and with the Local Government Board Regulations for continuous road haulage, and it can not only be used for direct ploughing, but also for driving threshing and other farm machinery. Its overall dimensions are: length, 13 ft. 8 in.; width, 5 ft. 8 in., and height to the top of the chimney, 9 ft. 9 in., while its weight, unladen, is 4 tons 17 cwt. The engine is of the compound type, with cylinders 5 in. and 7¾ in. in diameter by 8 in. stroke. It is fitted with link motion reversing gear of the Stephenson type.

Steam is supplied by a locomotive type boiler, designed for a working pressure of 180 lb. to the square inch, and furnished with28 tubes. The heating surface is 64.7 square feet, and the grate area, 3.18 square feet. There are, in the standard machine, two methods of feeding the boiler. One is by means of a ram pump fitted with a gun-metal plunger and valve boxes, and driven from the crank-shaft of the engine. The other feed is provided by an injector. Both pump and injector have their own independent check-valves. As an alternative to the feed pump, a second injector, or an independent steam pump, can be supplied, if required. There are two water tanks, one in the tender, with a capacity of 90 gallons, and the other usually arranged under the boiler, and holding 45 gallons. The combined capacity is, therefore, 135 gallons, and the two tanks are in connection with one another by means of pipes. For filling the tanks, a gun-metal water lifter, with 24 ft. of wire-bound suction hose and a strainer, are provided. The coal bunker capacity is 2 cwt.

The brake horse-power of the engine, as taken at the fly-wheel, is 25, and the fly-wheel, which is 2 ft. 9 in. in diameter by 5 in. wide, runs at 230 revolutions per minute. When it is intended that the machine shall be used for driving fixed machinery, a high-speed governor of the Pickering type, which acts directly on an equilibrium valve, is provided. The driving wheels, of the standard pattern tractor, are 5 ft. in diameter and 10 in. wide, but wheels 12 in. wide can be provided, and they can be furnished with extension plates so as to give an effective width of 18 in. Ordinarily, the tractors are arranged to give two travelling speeds—namely, three and six miles per hour—but additional gearing so as to give a third speed can be fitted, if required. The three speeds are then 2, 4½ and 7 miles per hour. The main gearing runs in a completely enclosed oil bath. The various speeds are controlled by a single lever, which is conveniently within reach of the driver on the foot-plate. The whole of the driving gear runs in fixed bearings, so that a constant depth of mesh of gear teeth is maintained. The drive is transmitted from the fixed spur gear to the differential gear plate on the hind axle by means of a floating ring, having two lugs on each side at right angles, the arrangement being exactly similar to that employed in the Oldham coupling. There is, hence, no limit to the free play of the springs. In the standard tractor both front and hind axles are mounted on a system of laminated springs, and the mounting is arranged on the Hoare patented system, in which the hind springs are placed under the axle and across the boiler, an adjusting bolt passing between the springs; a complete system of compensating levers is also provided. With this arrangement, the makers claim that the range of springs is greater than that of any other spring mounting at present on the market.

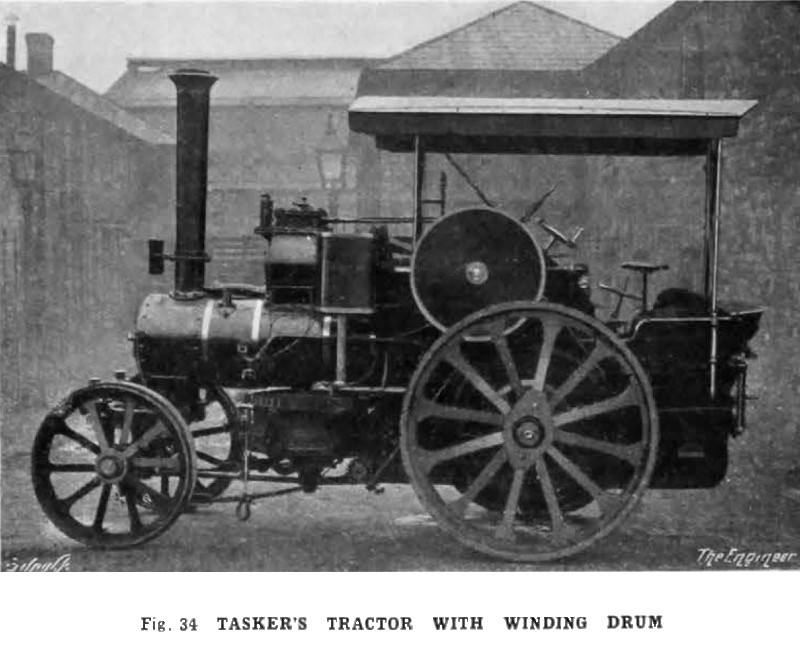

Another modification of the standard design is shown in Fig. 34, which represents a tractor having a winding drum placed under the boiler, and provided with 200 yards of ½ in. steel-wire rope and automatic coiling gear. Such tractors are intended for ploughing on the double engine system, each tractor alternately hauling the plough towards itself. This system can be used under conditions which would not be favourable for direct ploughing, and the machines, besides doing the heavy work of ploughing, can also be used for cultivating, harrowing, &c. The rope is also available for removing trees, roots, &c., from the land, and for the transport of trees from the land to the roads. The small size and comparatively light weight of these tractors, render them particularly handy for that class of work. The engines will, we understand, haul a three or four furrow plough, according to the condition of and the consistency of the soil.

Image courtesy of http://www.gracesguide.co.uk |

|

1918 W. Tasker & Sons, Steam Tractor with Winding Drum

1918 W. Tasker & Sons, Steam Tractor with Winding Drum

|

|