|

Title: |

1880 Article-T. M. Nagle, Portable Engine & Boiler |

|

Source: |

American Machinist, 15 May 1880, pg. 7 |

|

Insert Date: |

8/12/2015 8:42:35 PM |

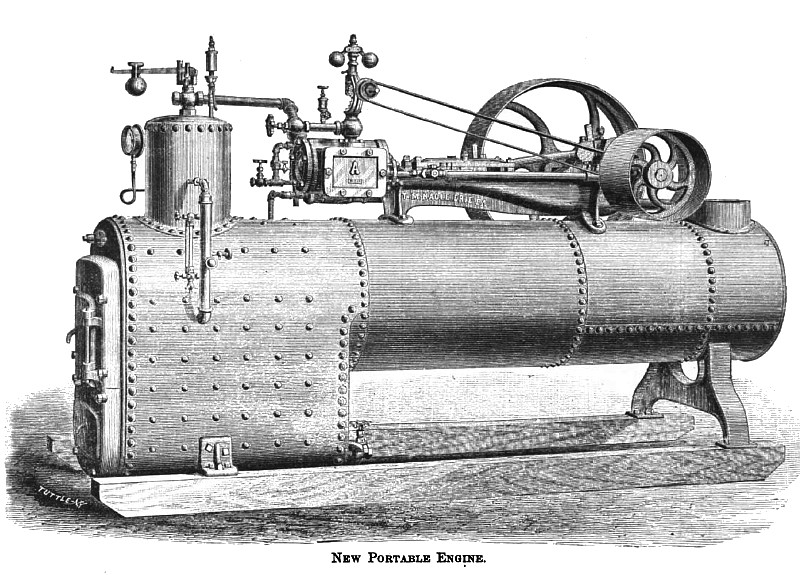

New Portable Engines

The engraving on this page represents a style of portable engine now being made by T. M. Nagle, Erie, Pa. These engines, of which five sizes are made, are built from entire new patterns with a view to securing the latest and best improvements. The aim has evidently been to make all parts plain, simple, strong and durable. All the wearing surfaces are unusually large. The frames which are strong are shaped so as to carry off all the waste oil. All the cylinders have hot air jackets which decrease the condensation in cylinder. The arrangement of the steam chest and steam ports is such that all the water forming in the cylinder is readily carried off. The ports extending below the bottom of cylinders, and the heaters being still lower, a perfect drainage is secured. The heaters are independent of the frames and all the pipes are easily accessible. The pumps are large and simple, firmly secured to cylinders and it is claimed unable to get out of alignment. They are provided with large air chambers and brass valves and seats, which can be readily taken out and replaced while the engine is working at full speed. The cranks are large and made of solid forgings. The pistons are fitted with self-adjusting steam packing rings and, it is claimed, do not require any attention nor do they cut the cylinder. The connecting rods are of wrought iron, with straps, bolts and keys to take up the wear of the brass boxes. The general design of the engine is neat and compact.

The boilers for these engines are of the plain water bottom furnace style, of the most approved proportions. They have large furnaces with removable fronts, giving easy access to flues, &c., for thorough cleaning and repairs; fusible plugs in crown sheets which will melt in case of low water in boiler and allow the steam to enter into furnace and put out the fire. The water bottoms admit of free circulation of water, and, it is claimed, are a perfect safeguard against fire under the furnace and allow the sediment to settle below the line of the fire. Hand-holes are provided in suitable places, in addition to the blow-off valve, to give easy access to the inside for cleaning. They are tested at 150 pounds hydrostatic pressure per square inch. Two sizes of engines are also made of the box-bed plate pattern, but having the same style of boiler as here shown.

The builder of these engines declares that the very best materials and workmanship are employed. |

|

1880 T. M. Nagle, Portable Engine & Boiler

1880 T. M. Nagle, Portable Engine & Boiler

|

|