|

Title: |

1880 Article-Fitchburg Steam Engine Co, Automatic Cut-Off Horizontal Steam Engine |

|

Source: |

American Machinist, 07 Feb 1880, pg. 3 |

|

Insert Date: |

7/7/2015 4:18:53 PM |

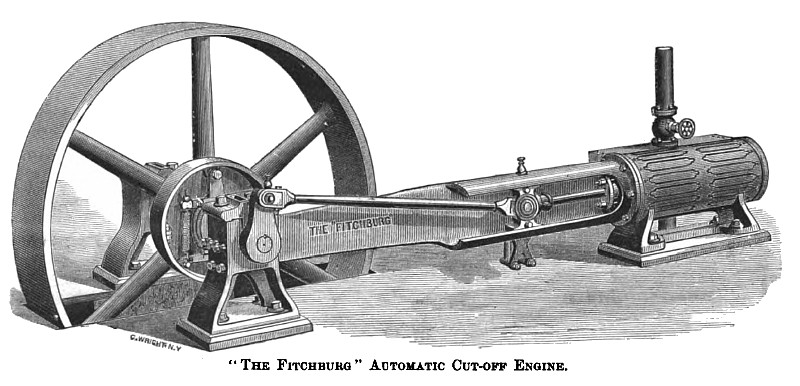

Fitchburg Horizontal Steam Engine

The advancement of practical knowledge as to the uses and abuses of steam, in connection with the means of transforming it into available work, has had the effect of stimulating different engine builders to exert their best efforts, and put to use all their talents, to either perfect the engines they have been making, or to design new ones in accordance with the latest principles of steam using theory and experience.

It is argued by eminent engineers of the present day that, from the uncontroverted experience of the past few years, other things being equal, the greatest economy in the use of steam is gained by using, for a given power, a cylinder small in diameter in proportion to those heretofore in common use, and, at the same time, a sufficiently high piston speed to make the work in foot pounds the same. In theory that gain should hold good to absurdly small cylinders and terrific speeds of piston, but practically piston speed must be confined below 800 to 1,000 feet per minute, owing to the fallibility of all metals. In fact, in the light of the most recent experience, it is safe to limit piston speed at 500 feet for smaller engines, and 700 ft. for larger engines up to 1,000 horse power—a speed double that which was considered the limit but a very few years ago; an engine thus requiring a piston with but half the area, and therefore, but half the radiating or condensing surfaces, the latter accounting in part for the economy attained.

In automatic cut-off engines, a second important point is, that the waste or clearance spaces contained between the piston head, at the end of its stroke, and face of the valve, should be reduced to the smallest possible per cent, of the piston displacement, in order that in early cut-offs the terminal pressure of expanded steam may be the least possible in proportion to the mean effective pressure throughout the stroke. In fixed cut-off or throttle valve engines this consideration does not necessarily hold, as by a proper proportion of the valve gear it can be nearly or quite obviated by compression at the end of the stroke, compression, also, having a valuable office in automatic engines.

In order to get the necessary high velocity of piston in such engines, there must be a compromise between too long and too short strokes, the former requiring a long and un-rigid bed or framing, the latter giving too high a number of revolutions to allow the centrifugal and reciprocating forces to be properly controlled. The proportion adopted in the engine we here illustrate, is that of a stroke twice the diameter of piston, and a piston speed of 500 feet per minute for a 10inch cylinder, increasing as powers increase to 600 feet for a 34-inch cylinder. There is also necessary a positive valve motion with such high speeds, or one which is not dependent upon the force of gravity alone, or assisted by a spring, but which at any number of revolutions, has the same sure opening and closing of ports. In the engine here shown, named "The Fitchburg," and built by the Fitchburg Steam Engine Company of Fitchburg, Mass., there are used entirely independent valves for the live steam and exhaust, so that, at whatever point steam may be cut off, the exhaust, release, and closure remain always the same, can be adjusted to exactly fit the circumstances in which any engine may be placed. The valves are of the balanced piston type, the seats being reamed and valves ground and "lapped," to a perfect fit, the weight of the valves being taken upon hardened steel spindles running in hardened steel bushings.

This company has probably the largest experience in the use of the piston valve of any firm in the country, as it has been used upon the well-known "Haskins" engine built by the same firm, for the past ten years, and in that time has fully proved its great value.

As steam is taken between the ends of the valve, the stuffing boxes need packing only very lightly against exhaust pressure.

The exhaust valve obtains its fixed or constant motion from the usual simple eccentric and straight connections, its action, to accommodate different circumstances, being varied by changing the relative position of the eccentric upon the shaft and setting it fast.

The cut-off valve is also actuated by a simple eccentric and straight rod connections; but the action of this eccentric is automatically regulated by the governor, so as to admit more or less steam as speed decreases or increases, by reason of changes in load or steam pressure. The governor is fixed upon the shaft and rotates with it, its parts being contained in a disk case, the centrifugal force of weighted arms, and the centripetal force of stiff-coiled steel springs (resisting the outward movement of the arms) being so connected to the movable eccentric as to properly control its movements, as described before.

As the control of the engine is thus dependent only upon the quick action of a "live" spring, changes of load, even to the full power of the engine, are instantly detected by it, and the steam is at once admitted according to the need of the power to be exerted.

The parts of the governor have but the slightest motion upon each other, limited to one-eighth of an inch in any case, and this only when load changes very materially, so that being made of steel, and of the nicest workmanship, they are almost beyond danger of being ever worn out or accidentally destroyed.

The valves of the engine are placed very close to the cylinder and use straight ports into it, reducing clearance to from 2 to 2½ per cent, of piston displacement. The cylinder is jacketed with a thick coating of a non-conducting compound, surrounded by iron or wood lagging, reducing radiation to its lowest point. The working parts are all claimed to be made of the best materials.

The whole engine is one of those exemplifying the high speed principles which are everywhere gaining favor with progressive engineers.

The builders are willing to furnish all information desired to those contemplating the purchase of an engine. |

|

1880 Fitchburg Steam Engine Co, Automatic Cut-Off Horizontal Steam Engine

1880 Fitchburg Steam Engine Co, Automatic Cut-Off Horizontal Steam Engine

|

|