|

Title: |

1880 Article-New York Safety Steam Power Co., Vertical Steam Engine |

|

Source: |

American Machinist, 17 Apr 1880, pg. 6 |

|

Insert Date: |

7/7/2015 8:33:46 PM |

Vertical Engines

During the past few years there has been a constantly increasing desire among manufacturers to secure an efficient and durable steam engine which would possess the greatest advantages.

The vertical engine seems to have developed more points of superiority than any other, for the following reasons. It occupies the least floor space. The design is very simple, and the frame, though possessing great strength, is of such a design that the least amount of material is used to secure that end. A heavy, bungling frame is thus avoided, and the engine has instead a neat and shapely appearance. The frame also encloses the working parts of the engine, which protects them .from injury, and also prevents the accidents which frequently happen to persons who come in contact with the moving parts of horizontal engines. Access to all parts is readily attained for inspection or repairs. As the working parts all move vertically there is consequently an equal amount of wear upon all sides of each part; besides, the friction is greatly reduced. On account of its simplicity, the price is much less than of a horizontal engine which will develop the same power. This is an important advantage to say nothing of the small amount of labor required to set them up. The lubrication is necessarily more perfect upon a vertical engine than upon any other.

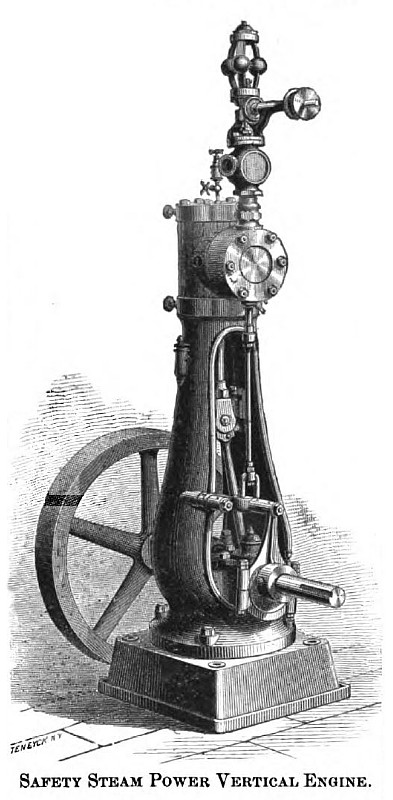

Vertical engines are not only adapted to light work, but are also used for the driving and rolling mills and blast furnaces, as well as the largest steamers. We illustrate herewith a vertical steam engine which is built by the New York Safety Steam Power Company. This engine is known as an independent or double crank, vertical engine.

It will be observed that there are two bearings for the crank-shaft, both of which are cast solid with the frame. The guides form a part of the frame, and are bored out when the top of the frame is faced off for the reception of the cylinder, consequently there can be no derangement of lines, and the friction is equally distributed. The shaft bearings are large, and present a large wearing surface, as well as ensuring great strength. The piston-rod is of steel, as is also the cross-head pin, which is lubricated through a hole in the center. The connecting rod is solid. The end connecting with the cross-head is furnished with best composition boxes, while the crank-pin bearing is composition-lined with Babbitt metal. The valve which admits steam to the cylinder is of the plain slide description. The valve-rod, which is of steel, passes through both sides of the steam chest, thus leaving the valve perfectly free. There is no thread upon the valve-stem, but a block of composition, with a set screw, is used instead. The joints and general workmanship are excellent. There is no oil or dirt thrown upon the floor from these engines. Each part is made to fit a gauge, therefore they are interchangeable. A number of the same class are built at the same time, which greatly reduces the cost of production. They are not only well made, but are nicely finished. In operation, they are virtually noiseless. During the past ten years, over one thousand have been put into use.

These engines are made in sizes from two to twelve horse power. Salesrooms of the New York Safety Steam Power Co., are at 30 Cortlandt St., New York. E. T. Copeland, General Agent. |

|

1880 New York Safety Steam Power Co., Vertical Steam Engine

1880 New York Safety Steam Power Co., Vertical Steam Engine

|

|