|

Title: |

1880 Article-D. J. Murray Mfg. Co., Gang Edger & Lumber Trimmer |

|

Source: |

American Machinist, 20 Mar 1880, pg. 5 |

|

Insert Date: |

7/7/2015 4:39:09 PM |

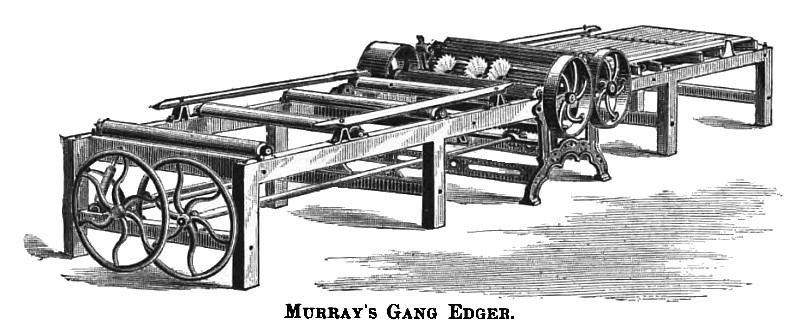

New Gang Edger and Improved Lumber Trimming Machine

Of the two wood-working machines, shown in the accompanying illustrations, the Gang Edger serves an important purpose, namely that of securing accuracy and uniformity in the width of the strips, scantling, etc., upon which it operates. It prevents waste and depreciation in value of the lumber, an economy which in this age of improvement and competition is indispensable for large profits. This object is effected by latching the hand wheels that man the saws, so that when changing widths, the movable saws will be set with precision and held fast while the saws are cutting. One of the movable saws is moved with a handle, which has a spring attached to the side of it working in a quadrant, with hatches to receive the spring. This saw may be instantly changed to saw 4, 6. 8, 10 or 12 inch widths; more notches can be filed, if necessary. The hand wheels have notches on the rim at 4, 6, 8, 10 and 12 inches, with springs attached to the floor to fit into the notches. These spring latches cannot wear loose and allow the lumber to be inaccurate. The saws are all movable; when four or more saws are required, they are put stationary. The gauges are of iron, 8 feet long, 5 inches wide, the edges planed to guide all the lumber perfectly. When four saws are used, most edgers need the movable gauge on the side next to the stationary saw, which is usually on the pulley side of a machine, and a stationary gauge next to a movable saw on the other side. The saw arbor has three bearings in a heavy iron frame, with an iron stand to make the outer one solid. The bearings are furnished with anti-heating arbor box caps. Rubber packing is used for adjusting when screwing down the cap; cotton wicking is laid in the channels against the arbor to prevent the oil from flowing too fast, which stops it altogether when the arbor is at rest. The idle rolls are of iron, turned, four inches diameter and 48 inches long, and they are mounted on substantial wood frames, that hold the rollers perfectly parallel in order to carry the lumber through straight. The machine itself is all built of iron and steel and is independent of itself, the wood frame being bolted to ears on the side. It is substantially built, and should run nicely for many years. As now constructed, this machine is regarded as one of the best Gang Edgers in use; it is still growing in favor, as it becomes known to manufacturers, on account of its substantial make, quantity and quality of work and facility of operation.

The working capacity of this machine in green white pine is from 75,000 to 125,000 feet per day.

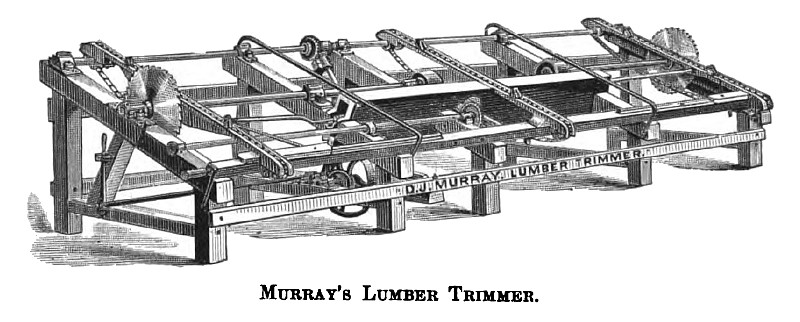

The practical working of the Lumber Trimmer, shown herewith, deserves careful notice. The saws slide four feet each on the arbors. By turning the crank one revolution each saw is moved 12 inches; one-half revolution moves each saw 6 inches. Both saws are moved by the one crank. The crank has a spring attached to the side of it that fits into notches, to hold the saws in their places when set to the exact length of cut desired. The lever on the left is to stop or start the transfer chains, which are driven by face frictions, and which can be changed to drive them fast or slow. Two sizes of this trimmer are made: No. 1 trims from 10 to 18 feet, size 5x20. No. 2 trims from 6 to 20 feet, size 5x22. These trimmers are first put together and finished ready for running. They are then taken apart, and each piece marked so that any mechanic can put them together, or they can be shipped all put together, as may be desired.

It is claimed that No. 2 will trim from 75,000 to 85,000 feet per day without crowding.

Both of these machines are manufactured by the inventor, D. J. Murray, of Wausau, Wis. (a point of importance in the lumber business), and have become popular in that locality. |

|

1880 D. J. Murray Mfg. Co., Gang Edger

1880 D. J. Murray Mfg. Co., Gang Edger

1880 D. J. Murray Mfg. Co., Lumber Trimmer

1880 D. J. Murray Mfg. Co., Lumber Trimmer

|

|