Manufacturers Index - Dauber-Bell Machine Co.

Dauber-Bell Machine Co.

Oshkosh, WI, U.S.A.

Manufacturer Class:

Wood Working Machinery

Last Modified: May 28 2016 11:52AM by Jeff_Joslin

If you have information to add to this entry, please

contact the Site Historian.

|

The C. G. Dauber Machine Co. was established in 1907 by Charles G. Dauber and L. A. Pomeroy, taking over H. C. Doman Co.'s line of dowel door machinery. In 1911 Edwin J. Bell joined the business and the name changed to the Dauber-Bell Machine Co. Bell brought with him some innovative ideas for a box-making machine that automatically assembled tongue-and-groove boards to a preset width.

Dauber left the business in 1912 but it continued under the Dauber-Bell name until 1921 when it became Bell Machine Co.

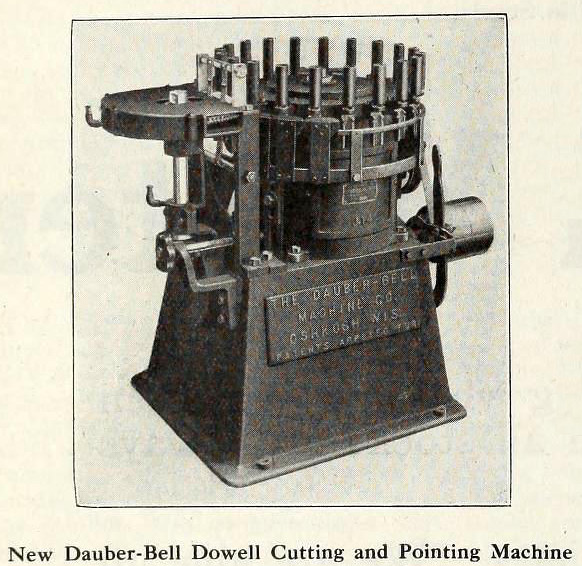

No shop complete with a dowel cutting and pointing machine. From 1913-01-01 Canada Lumberman and Woodworker

Information Sources

- 1907-05-30 Iron Trade Review.

The C. G. Dauber Machine Co., Oshkosh, Wis., has been chartered with an authorized capital of $10,000 by Charles G. Dauber, L. A. Pomeroy and C. W. Vande Walker.

- 1907-06-27 Iron Trade Review.

The C. G. Dauber machine Co., Oshkosh, Wis., recently incorporated, will manufacture Dowel door machinery, including an upright automatic door clamp, stile and rail borers, Dowel sticker, drivers, gluers, etc. The company is already doing good business in the central western states, and plans to operate through agencies in all parts of the country.

- 1911-05-11 Iron Trade Review.

The C. G. Dauber Machine Co., Oshkosh, Wis., has changed its name to the Dauber-Bell Machine Co., and has increased its capital stock from $10,000 to $30,000.

- 1911-06-01 Iron Trade Review.

The C. G. Dauber Machine Co., Oshkosh, Wis., which recently increased its capital stock and changed its name to the Dauber Bell Machine Co., advises that it is adding a concrete and steel building, 46 X 120 feet, for which contracts have been let. It manufactures dowel door, furniture and case shook machinery.

- 1911-10-15 St. Louis Lumberman.

The Dauber-Bell Machine Company.

A Word or Two About this Enterprising Company and Its Extensive Line of Machinery—A Machine that Makes Built-Up Boards.

The business of the Dauber-Bell Machine Co., Oshkosh, Wis., was started about five years ago. by C. G. Dauber and L. A. Pomeroy under the name of the C. G. Dauber Machine Co., the company purchasing at the time of organization the patents, patterns and good will of H. C. Doman for his line of dowel door machinery, Mr. Doman being a pioneer in the manufacture of this line.

The line was broadened and the business expanded until a new and larger plant became necessary. In the spring of 1911 E. J. Bell, who had been for some years superintendent of the plant of the Diamond Match Co., became interested in the business, the name being changed to The Dauber-Bell Machine Co. A complete new and modern plant of concrete and steel was erected, and has just recently been finished and put in operation. Realizing that there was a wide field in the furniture business for more modern machinery and that several machines in their line could be adapted to this work, the company started some time ago to add chair and furniture machinery to their line.

Amongst the machines developed along this line are their Completely Automatic and Semi-Automatic Dowel Drivers and Gluers for chair and furniture work. One of their automatic dowel drivers and gluers for chair seats will glue the holes and drive the dowels into forty pieces of chair stock per minute, any number of dowels desired being driven at one stroke, the gluing of the holes being done with their patent injector system, which effects a great saving of glue. Other machines along the furniture line are their Chair Back Gluer for gluing holes in chair backs, chair legs, chair seats, etc. This glues any number of holes at one operation, Coating the inside of the holes and leaving the face of the stock clean.

These machines met with so hearty a reception by the trade that other machines are now being brought out, among them a Power Clamp for pressing seat frames together. In the use of this clamp, the frames do not have to be started together by hand, as under the old method, the machine bringing the parts accurately together and squaring the seat up automatically as it comes together.

Among additions to their line of door machinery is their Automatic Stile Gluer, in which the stile is glued at one operation instead of dipping the rails, as in the old method, which they claim effects a great saving of glue and labor as well as making a better door. Also their Dowel Pin Cutting-Off and Pointing Machine, which cuts off and points dowels of any length or diameter, giving them any shaped point desired, the complete operation being done with one cutter-head.

A Continuous Board Builder

But probably the most remarkable of all the machines comprising the company's extensive line is Bell's Board Builder. It is something entirely new and revolutionary, and its inventor, E. J. Bell, holds pioneer patents on it, issued in May of the present year.

The machine is used in connection with any box board matcher, and as the tongued and grooved stuff comes through the matcher it is dropped into the hopper of this machine and the pieces are carded out of the hopper by a series of pusher heads under and between retarding and feeding rolls.

As the built-up board continues to advance on the table its forward edge impinges against an adjustable stop, previously placed for the width desired. The action of the board striking this stop shuts off the feed and also causes saws to separate the desired portion, and rollers to throw it from the table. As the piece so cut off is discharged from the table, the feed is automatically started up again. The capacity of the machine is exceedingly large and it requires only one man to operate it.

The machine will handle any width pieces, from the narrowest scraps that would pay to put a tongue and groove in up to 16 inches wide. It will also handle any thickness from 3/8 inches up to 2 inches.

- 1912-01-01 St. Louis Lumberman has an article on the Dauber-Bell Machine Co.'s "Dauber" new style gluer for assembling dowel-joined doors.

- Ad in 1920 issue of The Wood-Worker for Fader-Taggart Machinery Co. of Chicago, which says that they are a representative for Dauber-Bell.

- 1920 William H. Field Co. catalog that lists a "Bell" double cutoff saw; the saw is labeled "The Dauber-Bell Machine Co."

- Former Oshkosh Industrial Firms, by Steve R. Langkau, 2004.

...The company was originally known as the C. G. Dauber Machine Company, named after its founder Charles G. Dauber, and was located at 50 Ceape Street. They manufactured a small line of woodworking machines and tools. Manufactured products were used in every state in the nation as well as every province in Canada and many countries throughout the world. The furniture in your home, the windows and doors in your house, the brooms and mops in your closet, the lawn mower in your garage, your radio or television set and even your coffin could have been made in part by the machinery built by this firm.

In May of 1911, when Edwin J. Bell became associated with the business, the name was changed to the Dauber Bell Machine Company. The business had grown to a point where a new and larger factory was needed and it was built on Jackson Drive, just south of the former Soo Line Railroad tracks. There was ample land surrounding the plant to take care of any future expansion. When Mr. Dauber disposed of his interest in the company in 1912, the business continued under the name of the Dauber Bell Machine Company, with E. J. Bell as president, until September of 1921 when the name was changed to the Bell Machine Company. E. J. Bell was a skilled inventor and designer.

- From a 1938 issue of The Wood-Worker.

Passing of Edwin J. Bell

E. J. Bell, president of the Bell Machine Co., Oshkosh, Wis., died on June 20, at the age of 65; his death takes from Oshkosh one of the most outstanding industrialists. His reputation in his chosen field went far beyond the boundaries of his community and he was known and respected for his inventive ability and...

|