John A. Wood was a carpenter who was granted an 1870 patent for a self-feeding circular ripsaw that could also be used for rabbeting, grooving, and tenoning. He manufactured and sold the saw until at least 1879.

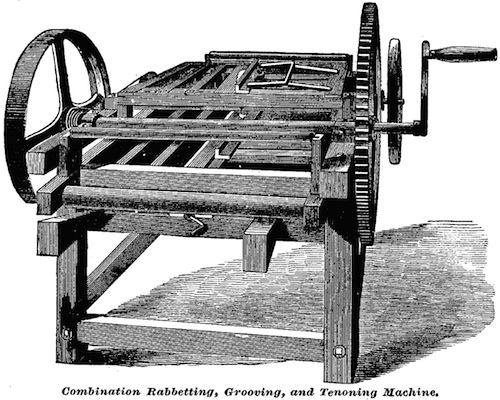

Etching from "Combination Wood-Working Machine" article in the March 1878 Manufacturer & Builder

Information Sources

- An illustrated article in the March 1872 issue of Manufacturer & Builder shows the "Eureka Circular Wood-Working Machine". The article notes that it received the machine was patented on 5 July, 1870, and it received the first premium at the Fair of the American Institute that year. The machine has a wooden frame with iron components, and weighed 350 pounds.

- The 1872 and 1873 issues of Manufacturer & Builder carried a text ad:

WOOD'S

Hand Circular-Saw Rabbeting and Tenoning Machine

Self-feeding.

Rips 700 feet per hour. Simple, durable, and easily operated. Patented 1870. Received first prize at American Institute Fair, New York, 1870. State rights and machine for sale. Send for circular.

J. A. WOOD, Rockaway, Long Island, N. Y.

- The March 1878 issue of Manufacturer & Builder had an illustrated article on J. A. Wood's "Combination Wood-Working Machine". The illustration appears identical to the one in the 1872 article.

Combination Wood-Working Machine

We represent in the adjoined engraving one of the time and labor saving machines, in the introduction of which this country at the present time stands foremost. The inventor, Mr. J. A. Wood, of Lawrence, Long Island, N. Y., is a carpenter by trade, and of course saw the need of a machine adapted to supersede the common hand-saw, and after several years of thought and experiment, produced a machine which he claims to be far superior to any hand-sawing machine ever offered for sale. It saves time and lumber in both sawing and planing. It is substantially built of the best material, weighs 350 pounds, occupies a space of 4 x 5 feet, and is capable of being run by steam or horse power. The many advantages of this machine are evident to any person acquainted with the circular-saw.

This machine is self-feeding; a combination of cone pulleys with self-feeding feed rollers, having a portion fluted or serrated to give proper hold upon the wood, enables the feed to be varied at pleasure. Directly underneath, and operating in connection with the feed-rollers, are loose roller upon which the wood to be saws rests for ripping. The boards are fed in under the saw-shaft and in the direction in which it revolves, thus insuring both cleanness of cut and economy of power. Upon the saw-arbor, chisels or other suitable cutting apparatus may be substituted for the saw. Above the main table used in sawing rests an upper table, and both are raised and lowered by means of double inclined planes, which are moved backward and forward by a crank-screw. The upper table, which can be readily removed when not required, is used for sawing or grooving as desired. Both tables have adjustable guides, and are provided with rollers at their respective levels, over which the stuff is fed. Besides being strong, durable, and inexpensive, the machine can be readily repaired, and it not liable to derangement. It, moreover, requires no skilled and expensive labor to operate it, a boy being quite able to cut 13 feet of 1-inch boards per minute on it.

The inventor is now prepared to furnish the machine at a reduced price to all who wish it, and trusts that excellence of material and build, cheapness and durability, variety and quality of its work, and facilities for changing it, will give perfect satisfaction. It obtained the first premium at the American Institute Fair, New York, in 1870, and silver medal in 1875.

- Brief mention in the January 1879 issue of Manufacturer & Builder that hits the highlights of the much longer March 1878 article.