Manufacturers Index - C. B. Rogers & Co.

C. B. Rogers & Co.

Norwich, CT, U.S.A.

Manufacturer Class:

Wood Working Machinery

Last Modified: Nov 9 2020 8:08PM by joelr4

If you have information to add to this entry, please

contact the Site Historian.

|

Caleb B. Rogers got his start in the woodworking machinery business working for the J. A. Fay & Co. The early history of the company is somewhat confusing as it appears that Rogers was for a time working for both Fay and his own company. Some ads indicate that the C. B. Rogers firm was founded in 1841; at that time Rogers was a director of J. A. Fay & Co., and in that year he constructed a factory in Keene, NH, for J. A. Fay & Co. It seems that Rogers operated the factory, and all machines were made under contract to J. A. Fay & Co.

In 1848, Rogers, again partnering with Fay, built a second factory in Norwich, CT where he supervised the entire plant. A few years after that, a third factory was built in Worchester, MA, again for manufacturing Fay machinery under the supervision of Rogers.

In 1854, upon the death of J. A. Fay, Fay's interests in the Norwich firm was transferred to Rogers and took over the business and apparently at least some of the machines were moved to his own line under the name of C. B. Rogers, & Co. They were one of several companies to claim that they were "successors to J. A. Fay & Co." Ultimately, Fay's Cincinnati operations under William H. Doane won the right to continue using the Fay name.

Rogers, who had become a curmudgeonly elder statesman of the industry, died in 1871. Over the ensuing decades C. B. Rogers & Co. continued to make a full line of woodworking machinery.

In 1897 C. B. Rogers & Co. merged with ten others to form American Wood Working Machine Co. The 1980 book Planers, Matchers and Molders in America says that Rogers's specialty was molders, but they also made matchers, including the "New England Planer and Matcher."

|

|

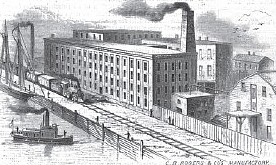

| C. B. Rogers & Co. Exterior Factory View |

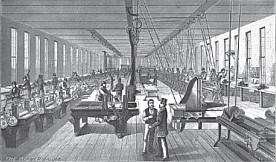

C. B. Rogers & Co. Interior Factory View |

Lyman Gould

Lyman Gould became the president of C. B. Rogers & Co. after the death of C. B. Rogers himself. Gould held some patents that are believed to have been used by the company. He was also the president of the Uncas Bank of Norwich, CT. The following obituary appeared in the February 1891 issue of Manufacturer & Builder: We regret to announce the recent death of Lyman Gould, president and treasurer of C. B. Rogers & Company, the extensive and well-known manufacturers of wood-working machinery at Norwich, Conn. Mr. Gould was born in Stoddard, N. H., in 1819, and was consequently in his 72d year at the time of his death. He had received in his youth an excellent mechanical training, which, associated with natural gifts of a high order, were the foundations of an eminently useful and successful career. He went to Norwich in 1855, and some years later entered the establishment of C. B. Rogers, with which he was to be so long and honorably associated. Shortly after his entrance into the Rogers shops, he was called upon to design and superintend the constiuction of the new factory at present occupied by the establishment.

Later on, when the present company was incorporated, he was chosen secretary, and upon the death of Mr. Rogers, was successively elected president, and president and treasurer, which last connection he held until his death.

Mr. Gould combined with mechanical ability an excellent knowledge of the patent law and sound judgment in business matters. Personally, he was a man of fine character, upright and exemplary in his relations with others. He was highly esteemed in the city where the major portion of his life was passed, and Norwich, by his death, loses one of its representative citizens.

Information Sources

- Scientific American 07 Jan 1880.

- 1855 mention and 1867 ad in Scientific American

- Various genealogy sites give Caleb Baker Rogers' birth and death as 1806-06-26 and 1871-11-22, respectively. Both occurred in or near Norwich, CT.

- 1875, 1886 mentions, 1883-1891 ads, and numerous 1882-1888 articles in Manufacturer & Builder

- 1873, 1876, 1883, and 1886 catalogs. The 1886 catalog lists "planers, planing and matching machines, surface planers, hand planers and cornering machines, knife grinding machines, a machine for setting matcher-cutters, four side molding machines, sash machines, timber tenoning and gaining machines, timber gaining machines, a rotary car mortising and boring machine, bridge and car mortising machines, a large power hub mortising machine, band saws, a cabinet jointing machine, a pedestal shaping machine, a fret scroll saw, vertical and circular re-sawing machines, a large railway saw, an over cutting-off carriage saw and gaining machine, etc., etc."

- A J. A. Fay & Co. ad from 1856 lists C. B. Rogers as the director of the Norwich operations of their company; it is not clear whether "C. B. Rogers & Co." constituted their Norwich operations, or whether Mr. Rogers was working for himself and J. A. Fay at the same time.

- An 1874 Manufacturer & Builder article says, "The business of this firm dates back to 1841, while in 1848 it was established at Norwich, CT, under the personal direction of Mr. C. B. Rogers. In 1863, a joint stock corporation was formed, with a capital of $200,000, under whose auspices the business now continues." That same 1874 article says that he had about 200 employees.

- An 1883 Manufacturer & Builder says that they had about 100 employees.

- Planers, Matchers and Molders in America notes that C. B. Rogers and J. A. Fay jointly developed the first successful roll-fed molder ("sticker"), which was produced by both of their respective companies. This machine had wooden pulleys and working table. Also according to that book, in 1862-1863 this company was one of three to introduce molders with cutter-head shafts supported on both ends; the others were S. A. Woods and Charles R. Tompkins.

- A Photo Index entry showing a C. B. Rogers miter chopper mentions that the machine is labeled as a Hall's Patent Mitre Machine. The only Hall patent for a miter chopper is the 1858 patent 21,194, granted to Stephen W. Hall of Williamsport, PA. The patented features (guides for the sides of the blades to prevent them from deflecting) do appear to be present on the C. B. Rogers machine.

- Carriage and Wagon Makers Machinery and Tools by Kenneth L. Cope, 2004 page 150

- The following is an excerpt from The Manufacture of Wood Working Machinery, an article in the 1880-01-17 Scientific American.

Among the various mechanical industries of the world there is none--with perhaps the exception of iron--which is more widely spread or employs more capital and labor than the working of wood in the manifold uses to which it is applied. In the present advanced state of manufactures machinery is employed for nearly every process to which wood is subjected. From the wooden toothpick to the railway car or the palace of royalty, machinery is used for producing the required form. The manufacture of machinery for working wood has become, therefore, one of our most important industries, for only by securing the greatest perfection in the machinery employed, can the best results be obtained.

We have selected as the representative of this industry the house of C. B. Rogers & Co., at Norwich, Conn., the oldest as well as one of the largest engaged in this business. The house originated at Keene, N. H., in 1833, when Mr. J. A. Fay commenced the manufacture of mortising and tenoning machines for sash and door work. Previous to that time, with the exception of the Woodworth and Daniels planers, saws, and a few special tools, very little wood-working machinery was used. The new machines made by Mr. Fay met a ready sale and increased demand, and in 1848 Mr. C. B. Rogers engaged with Mr. Fay in the business, opening a factory at Norwich, Conn., for the purpose, and bringing out the sash sticking machine, which met with such an unprecedented demand that for over three years one machine per day was the average sale. A few years later a shop was started at Worcester, Mass., which was devoted to Woodworth and Daniels planers.

In 1861 the death of Mr. Fay, together with the need of condensation of the business at some central shipping point, made it advisable to remove the entire business to Norwich. The firm was made into a joint stock corporation, a large works erected to accommodate the whole business, and the name, which up to this time had been J. A. Fay & Co., was changed, and the present title, C. B. Rogers & Co., adopted. The history of the establishment from the start has been one of progress, and the inventive talent of the managers has been kept constantly employed to keep pace with the demand for improvement. Many of the most indispensable machines in use originated with this house--notably the power mortiser, tenoning machine, sash sticker, and four side moulding machine.

The works, of which the central cut of our first page illustration is a fine representation, are located in the city of Norwich, Conn., on the banks of the river Thames. The location is most excellent as regards freighting facilities--an important item with this class of goods--the city baing midway between Boston and New York, with a daily line of steamers to the latter, and two railroads centering there, by which freights may be forwarded expeditiously to all points, and are by special arrangement to all Western points at the regular New York freight tariff. The works, including the foundry, cover nearly three acres of ground. The manufactory surrounds three sides of a quadrangle, and consists of the main building, 125x45 feet, four stories, with blacksmith shop, 30x25 feet, attached; a wing, 65x40 feet, four stories; and a second wing, 50x20 feet, three stories. The fourth side is occupied by a storehouse, 100x30 feet, three stories, for lumber and coal. The factory has about 40,000 feet of floor space.

Entering the works at the north end, ground floor, we come first to the motive power, steam, applied to an 80horse power high pressure double engine, built by this company, running 125 revolutions, and so delicately adjusted in its valve motion that the stoppage of half the tools in the building can scarcely be detected in the speed. Passing the engine, we enter the "planer room," so-called from its being devoted exclusively to the manufacture of planing and matching machines. Our artist has sketched this room entire, with the various planers in process of construction. Of this class of tools this house make twenty different sizes and styles, from the diminutive "Pony," so-called, to the planer and matcher weighing from four and one half to five tons. The greatest care is used in the construction of these machines, and the latest improvements and processes are applied. A recent oue is the use of cast steel for all cylinder heads, as well as for the smaller gearing where the wear is greatest. The severe tests to which these machines are put have always proved successful and eminently satisfactory to the user. In the center of the room, but upon the outside, is an elevator running to the fourth story, and sufficiently powerful to raise the heavy planers to the street level for shipment.

Leaving the planer room, we pass through a store room filled with bar iron, of all shapes and sizes, and enter the blacksmith shop, which has six forges, two trip hammers, power shears, and all facilities for the various forgings. From here we ascend to the second floor, machinist room. This floor is engaged on moulding machines, of which seven sizes are made; sash machines; mortisers, twelve sizes; tenoners, seven sizes; band saws, three sizes; scroll saws, railway cutting off and splitting saw frames, resawing machines, and various other tools.

Passing the casting room, where tons of castings are in process of cleaning, we ascend the main staircase to the third floor or " wood room." This floor is engaged upon woodwork; framing machines, making foundry flasks, pattern work, of which a large amount is required in the production of new machines and alteration of the old. Although iron frames are the rule for most machinery, some of the wood frames are still retained as being lighter and cheaper--as the sash machine, tenoner, saw tables, etc. The frames retain their position equally with iron, but to insure this a large stock of hard wood is kept in store and seasoned for years before using. On this floor is the paint room, where the finishing touches are applied and the gray iron rendered more agreeable to the eye. At the south end of the room--the foreground in the sketch--is one of the most important departments in the building, where every machine before being shipped is thoroughly tested on the work it is designed to perform, and any error or oversight in the construction corrected. This was for many years a system followed only by this house, and its value has been amply proven by the universal success of the machines sent out.

Many purchasers have but a limited knowledge of machinery, and it is a great assistance to them to receive their machines all set and with tools prepared ready to set at work. The machine shown as being tested is a vertical tenoning machine made for tenoning car sills and doing the heaviest work with great ease and rapidity. The company have recently completed a machine of this class for working oak timber 16 inches square, cutting a double tenon 8 inches deep at one cut. A companion machine to this is the rotary car mortising machine, which works mortises 12 inches deep, 15 wide, and any length required, the timber being moved by power, and the whole operation almost automatic.

Upon the fourth floor is the "machinist room." This is similar to the second, but engaged on a lighter class of tools, with one exception--the inside head moulder, which is one of the finest tools in use. It weighs 3,500 pounds, and works moulding up to 12 inches wide, and by special adjustments is capable of producing 50,000 feet of narrow mouldings per day, a feat said to be unequaled by any other machine. Among the other tools are: iron frame tenoning machines, whose advantages consist in great facility of adjustment and ease of operation; upright shaping machines, five sizes; boring machines, one ingenious two-bit machine for cabinet work, cabinet jointers for piano work, Reidy's patent ironing and mangling machine, a specialty recently introduced into this country by an English patentee, its 'peculiarity being the method cf heating the roll by a combination of gas and air. Last, but not least, in one corner, occupying but little space, is the manufacture of Boardman's barbed blind staple, which was invented by an employee of the house, and has been made by them for over twenty years. Here several machines arc running constantly, for some time past night and day, to produce these little articles, 2,200 of which weigh but a pound, and of which orders have been received within three months for upward of forty tons. It would seem the work of a lifetime to produce such an amount, but the machines are tireless, and, like Oliver Twist calling for more, they consume it in their insatiate maws, and the finished staples drop from them like the rain drops.

The three upper floors of the main wing are filled with finished tools ready to be shipped out on order, and the long lines of machines in dozens or half dozens of a kind make a fine display. On the third floor of this wing, a light, pleasant room, with a fine view of the river, is used for draughting the many new designs and improvements required in the business. Something in this line is in process constantly. One of the most recent is the large hub mortising machine, shown in the right hand cut of our illustration. This was produced on a requirement for a machine to mortise a hub 16x18 inches, a task as yet unaccomplished. The machine shown does the work successfully, mortising 8 inches deep in solid hard wood, and although very heavy and powerful--weighing 3,500 pounds--with as much ease to the operator as one of the lighter door mortisers.

This house have always given special attention to perfecting machines for specially difficult classes of work. Complete sets of machinery for making lead pencil woods and finishing the pencils were perfected by this house and furnished to the Messrs. Faber and others. Machines for making meat skewers, turning them out by the million, and many other specialties have been produced, it being only necessary to state the work to be done and something will be invented to meet the emergency. This company work their iron from the pig, the castings being produced in their foundry, of which an interior view is given. It has about 15,000 feet of floor space, two cupolas, one of seven tons capacity, large core ovens, cranes, and every facility for doing a large quantity of work. The present production is from three to four tons on alternate days. The quality of iron is an important item in this class of tools, and the company are able, by making their own castings, to insure the best. Attached to the foundry is the pattern house, 30x15 feet, two stories, and packed to overflowing with the patterns used.

The offices of the house are in the second wing of the works, fronting the street. Here are the accounting department, the correspondence which is extensively carried on with all parts of the world, and in addition to these is a constant production of catalogues, cuts, and circulars descriptive of the various machines. A catalogue is issued frequently of 175 pages, giving full information relative to the 125 different machines made by the house, among which are tools embracing in their ranges of work house building, sash and door, furniture, cabinet and musical instruments, wheels and wagons, railway cars and coaches, to which class special attention is given, planing mills, lumber producers, mouldings and picture frames, brooms, curtain rolls, and in fact for nearly every purpose to which wood is applied. The house has a ware-room at 109 Liberty Street, New York, and their shipments extend to Great Britain, France, Germany, Sweden, Austria, Russia, Australia, New Zealand, South America, and every corner of North America, and in nearly every country named the house has a ware-room with machinery in stock.

The machines have been exhibited at every exhibition of note from the Crystal Palace down to the present time, and over 1O0 medals in gold, silver, and bronze attest the competitive merit of the exhibits.

The present officers of the company are: Lyman Gould, President; R. M. Ladd, Treasurer; and B. H. Rogers, Secretary and Superintendent.

|